AEC-Q200-compliant evaluation of the temperature of electronic components

The number of electronic components used in automobiles is rising due to an extensive range of self-driving technologies like advanced driver-assistance systems (ADAS) and infotainment functionality, including in the form of human machine interfaces (HMIs). Electronic components used in automobiles must deliver a high level of reliability. To help ensure they do, the AEC-Q200 standard for reliability testing was developed for electronic components used in automobiles. The Automotive Electronic Council (AEC), which formulated the standard, includes automotive component manufacturers, electronic component manufacturers, and semiconductor manufacturers. The principal tests are temperature tests, which are used to verify changes in component characteristics in a high-temperature environment, including temperature cycle testing in which the temperature is varied. Variations in the characteristics of electronic components are verified before, during, and after testing.

Issues

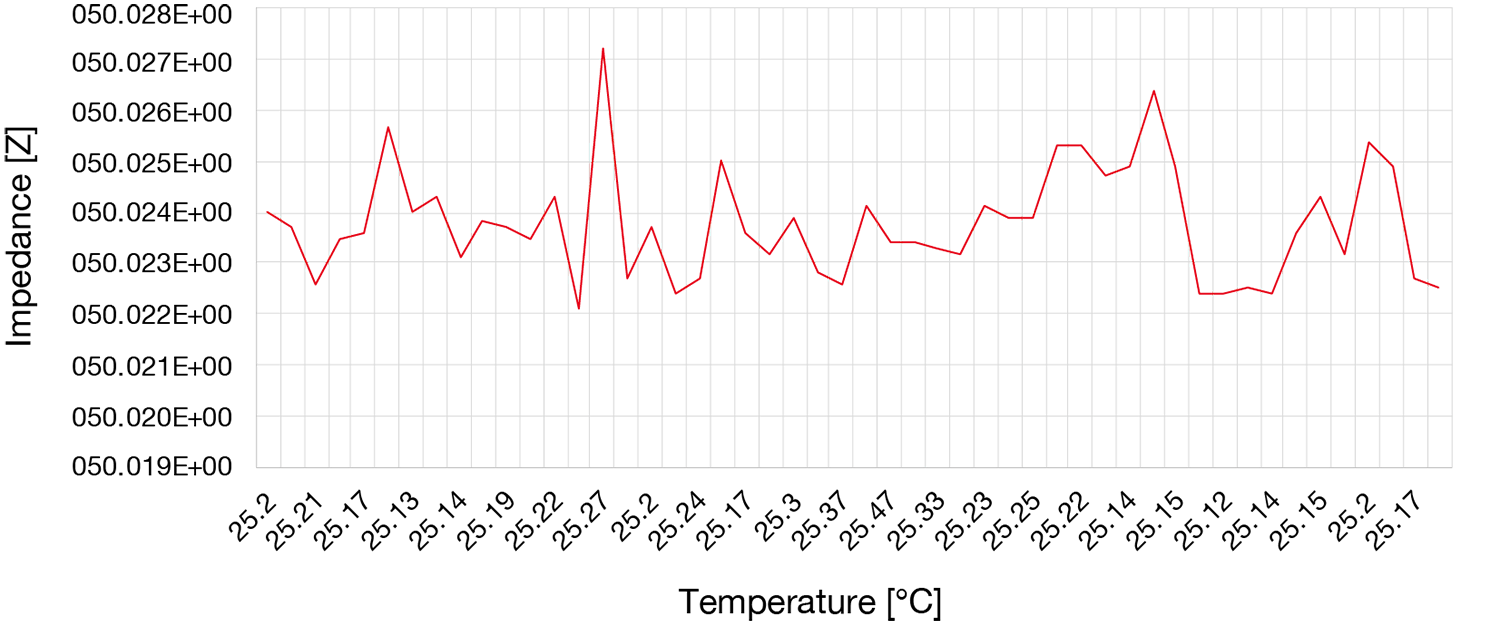

It's necessary to check how the characteristics and properties of electronic components change in response to changes in temperature. One effective method for doing so is to review a graph with temperature on the X-axis and the desired characteristic on the Y-axis. It’s typical to create such graphs using spreadsheet software and to use them in evaluation reports. However, different instruments are often used to measure electronic components’ characteristics and record temperature over an extended period, and it’s troublesome to aggregate data from different sources.

Solution

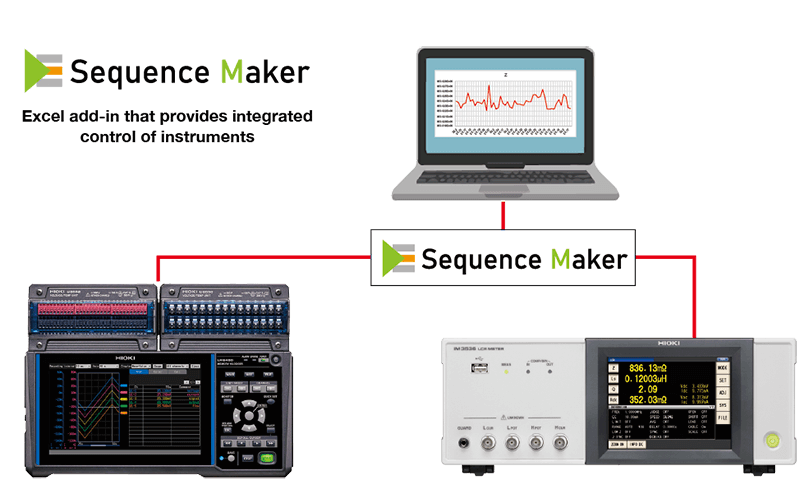

“Sequence Maker” is an Excel add-in that provides integrated control of measuring instruments. It supports USB, RS-232C, LAN, and GP-IB as communications interfaces. It also supports VISA, a model-agnostic communications driver for instruments. Since it can automatically search for and connect to instruments that are connected to a PC, you can implement the desired control by noting the control commands you wish to execute in order in the Excel file.

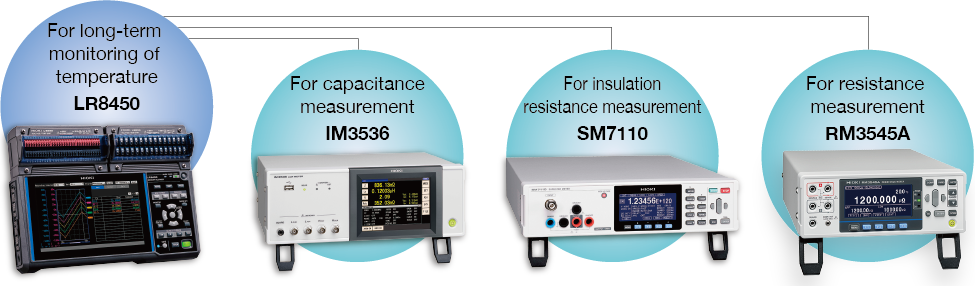

The add-in provides an instrument as appropriate for measuring the electronic component’s characteristics.

For details, please see the following site: https://sequencemaker.hioki.com/en/.

Click here to download an Excel sample.

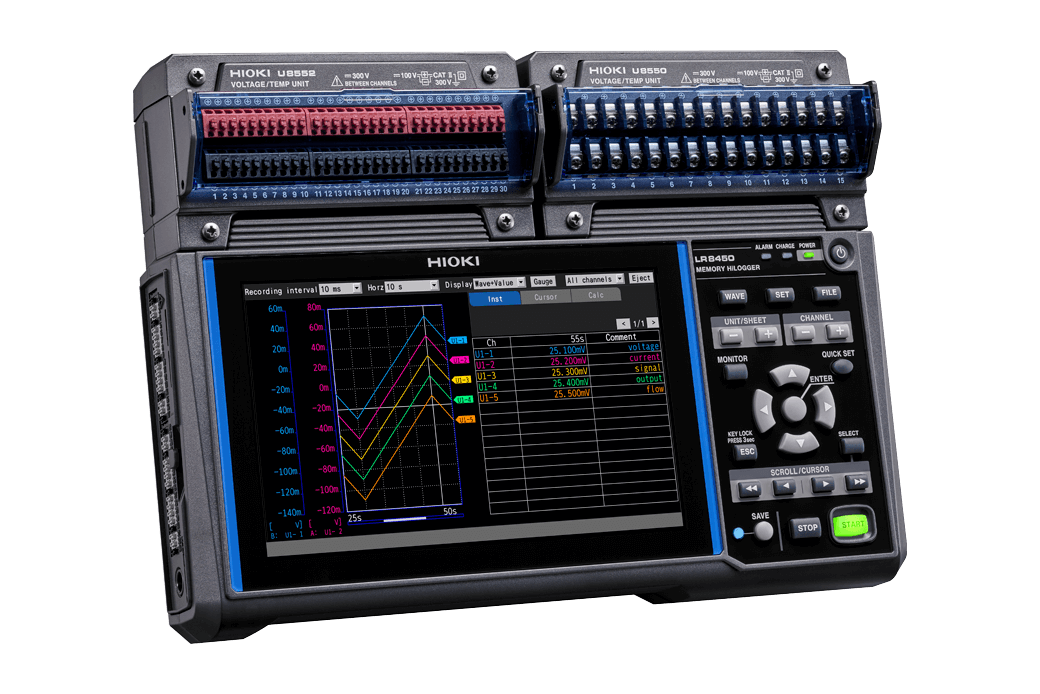

Case 1: Temperature variability of capacitance in a capacitor

(Equipment used: LR8450, IM3536)

Case 2: Temperature variability of insulation resistance in a capacitor or varistor

(Equipment used: LR8450, SM7110)

Case 3: Temperature variability of resistance values in a resistor or signal line

(Equipment used: LR8450, RM3545A)

Measured data

This example plots impedance on the Y-axis and temperature on the X-axis. In most cases, component temperature variations are evaluated after placing the component in a constant temperature chamber whose temperature can be controlled.