Measuring the impedance of piezoelectric ceramics more quickly, accurately, and easily

Realizing a testing system that can accommodate increases in production volume with an impedance measurement time of 0.5 ms per point

Featured customer

Company Z leverages development and production technologies it has developed over many years to develop, manufacture, and sell electronic components that are used in a variety of products. In recent years, the company has been focusing on developing new piezoelectric ceramics products and producing them at volume in response to rising demand from customers such as information and communications equipment manufacturers and automotive part manufacturers.

Background

Measuring the impedance of piezoelectric ceramics more quickly, accurately, and easily

For a facility manufacturing piezoelectric components operating at a given number of hours, production volume–whether the plant is manufacturing one part or 1 million parts–has little impact on labor costs and heating and light expenses. In other words, profit will increase in proportion to production volume, which means that companies can boost profitability by shortening the amount of time required to produce one unit. However, the benefits of faster production can only be realized if the time required by quality inspections can also be reduced. When the time available for measurement of impedance, a key parameter for evaluating the characteristics of electronic components, is reduced, accuracy is sacrificed; conversely, accurate measurement requires more time. This trade-off makes the process difficult to accelerate.

In recent years, Company Z, which develops, manufactures, and sells piezoelectric ceramic products, has run into this wall as it tried to strengthen its production system. The company has used instruments from Hioki competitors in the past but found them ill-suited to measuring large quantities of electronic components quickly, for example in 100% inspections. For example, it had difficulty measuring resonance frequencies while switching frequencies quickly during shipping inspections of its piezoelectric ceramic products. Other complaints included the instruments’ high cost, which meant that it couldn’t easily purchase enough of them to accommodate planned increases in production volume, and excessive specifications, which meant that many functions went unused.

As smartphones and other electronic products using sensors and actuators become more familiar parts of consumers’ lives, the market for electronic components like semiconductors and piezoelectric elements is expected to continue to grow.

With demand for piezoelectric ceramics forecast to continue to rise, Company Z understandably sought instruments that could measure impedance accurately, quickly, and easily without sacrificing production volume.

Key considerations that led the customer to choose Hioki

Impedance sweep measurement with overwhelming speed and ease of use

While there are instruments that can measure impedance precisely and at high speed, they aren’t suitable for use on Company Z’s production lines, for example due to their large size, high cost, and complex control requirements. The company also identified a number of other requirements, including that the instruments provide extensive functionality for generating pass/fail judgments during shipping inspections, along with ease of use, and that they be able to quickly switch settings so that they could test large numbers of electronic component models on the same line.

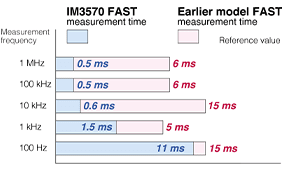

Company Z ended up seeking advice concerning impedance measurement on production lines from Hioki, with which it had a connection through a previous project. Hioki proposed the Impedance Analyzer IM3570 as a way to solve the problems Company Z was experiencing. Despite its compact size, the IM3570 can perform sweep measurement by continuously varying the measurement frequency and measurement level, and it brings to the table overwhelming measurement speed at 0.5 ms per point. For Company Z, this speed is an essential advantage that enables it to manufacture more piezoelectric ceramic products and test them all prior to shipment.

Other advantages included the IM3570’s ability to automatically search for resonance points during testing of piezoelectric ceramics and its ability to generate pass/fail judgments quickly. Additionally, simple configuration means the instrument can deliver continuous, high-speed measurement, even when testing different electronic components on the same line. Company Z has also praised the instrument’s integrated touch panel, which allows intuitive operation. In the end, the company made a decision to purchase the IM3570 based on a comprehensive evaluation of price and ease of deployment.

Benefits

Realizing a testing system capable of accommodating increased production volume through high-speed measurement at 0.5 ms per point

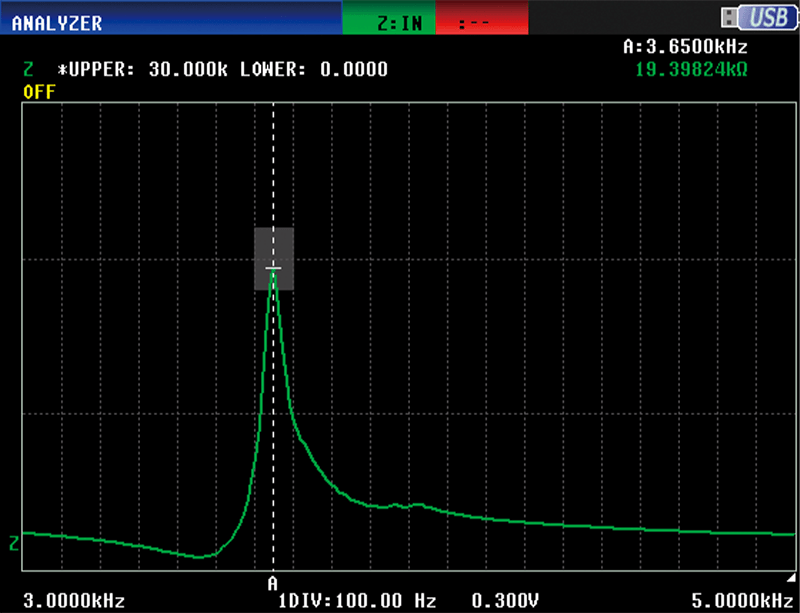

Resonance points and resonance sharpness are key indicators in testing of piezoelectric ceramics, and the IM3570 can generate judgments by automatically searching for them at high speed. The instrument also provides 5-count resolution (under 1 kHz, 0.01 Hz resolution) across a frequency band of DC and 4 Hz to 5 MHz. Moreover, its extensive judgment functionality means it can easily generate pass/fail judgments for a variety of electronic components.

Frequency sweep measurement Z peak comparator function

Frequency sweep measurement Z peak comparator function

The IM370's ability to perform stable, high-speed, accurate measurement not only helped improve inspection process yields, but also enabled Company Z to put in place an inspection system capable of accommodating its plans for increased production in response to market demand.

Prior to the purchase, the company had set the target of reducing impedance measurement time to about 0.6 ms per point in order to strengthen its production system. With the IM3570 purchase, the company was able to exceed that goal.

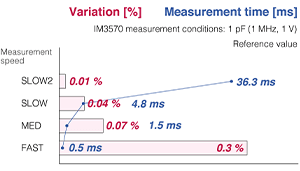

Comparison of measurement time of IM3570 and Earlier model

Comparison of measurement time of IM3570 and Earlier model Repeatability when measured 100 times

Repeatability when measured 100 times

As the company continues to use the IM3570 over the long term, Hioki will regularly review features such as internal calculation processing.

Currently, the measurement time is 0.5 ms per point, which is less than when the company purchased the instruments. That accomplishment was achieved through both companies’ efforts to trim measurement times as much as possible in order to increase production volume.

Company Z recently increased production to keep step with the growing market for piezoelectric ceramic products. There can be no doubt that the IM3570 played a role in this smooth expansion of the company’s business.