Monitoring of Battery Voltage and Temperature during Charge and Discharge Testing

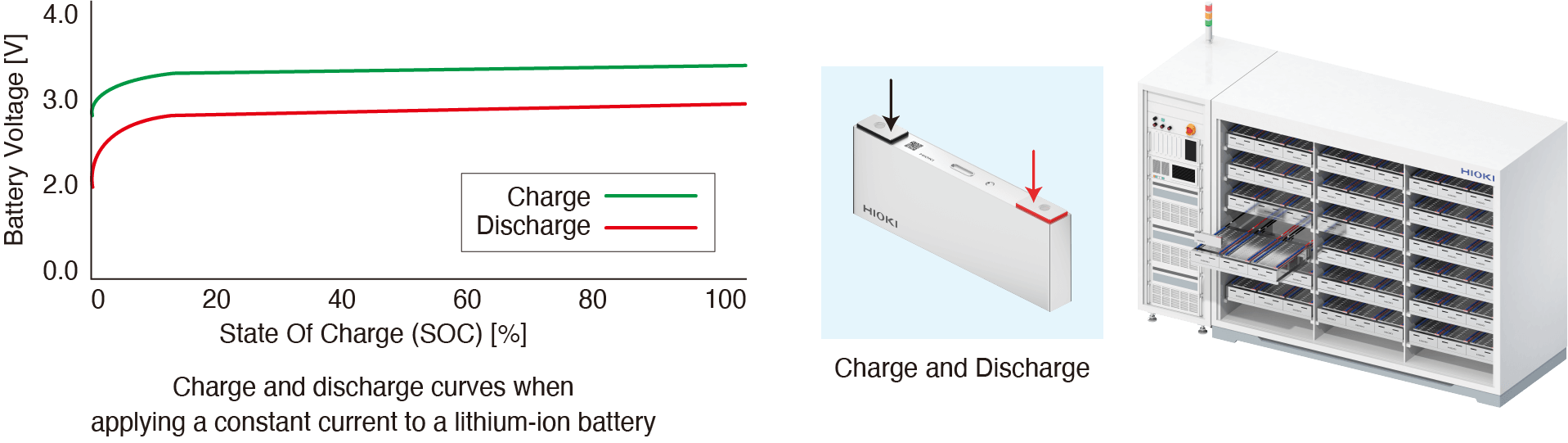

The battery manufacturing process includes a step where batteries are repeatedly charged and discharged, causing the battery to under go a chemical reaction known as formation. Formation, which enables the battery to store energy in a stable manner, is a key process that affects battery performance. It’s necessary to record cell voltage and temperature while the battery is charged and discharged.

Purpose of recording cell voltage and temperature during charge and discharge testing

Cell voltage and temperature are recorded during charge and discharge testing for the following reasons:

- To check the battery status

- To control the charge and discharge equipment

- To record data to ensure traceability across battery production processes

- To accumulate battery performance and safety data

- To identify defective batteries and grade batteries based on performance

Recording battery cell voltage and temperature

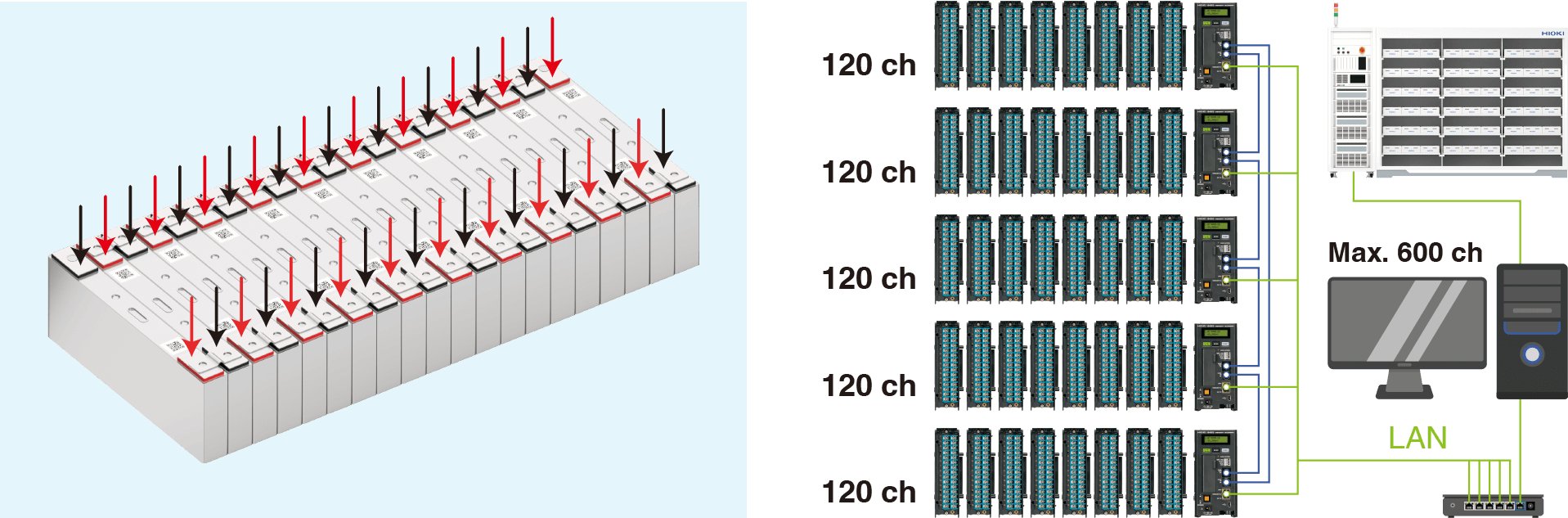

Since charge and discharge testing involves controlling large currents, measured values are prone to exhibit the effects of noise. The 8423 can accurately record cell voltage and temperature data in noisy environments. Moreover, the instrument minimizes cost and space requirements to eliminate waste because it lets users add 15-channel Voltage/Temp Units as necessary to accommodate the required number of connections.

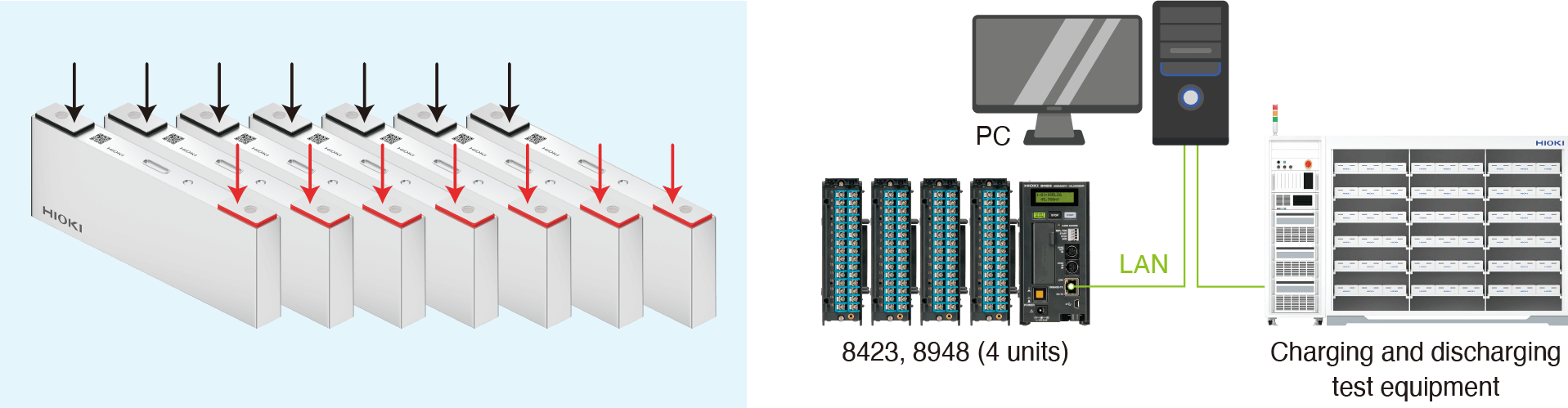

Charge and discharge testing of battery modules and packs

When measuring cell voltage and temperature in modules and packs, which connect cells in series, important considerations include the number of channels and the rated terminal-to-ground voltage. The 8423 can record voltage and temperature data across 600 channels (*1) at a 10 ms sampling rate. The instrument has a rated terminal-to-ground voltage of 600 V AC/DC.

- *1:Synchronous sampling of 8423 x 5 units