On-site power efficiency measurement of an EV fast charger

Introduction

Electric vehicle (EV) chargers are the unsung heroes behind a sustainable future of effective replacement of the internal combustion engine by EVs. Fast chargers, also known as DC chargers, have taken a prominent position in the industry, especially as the capacity of electric vehicle batteries continues to increase. The substantial increase in battery capabilities has increased the need for EV fast chargers, since conventional (AC) chargers would simply take too long to charge.

Fast chargers (DC chargers) stand out from normal chargers (AC chargers) in their approach to power conversion, executing this process outside of the vehicle, within the charger unit itself. This distinctive method results in a higher voltage and amperage output, significantly accelerating the charging time for EVs. The charging time makes them a more favorable choice in public facilities.

In the power conversion process inside the EV fast charger, power loss cannot be denied. In this article we will take a look at the on-site power efficiency measurement of an EV fast charger and equipments required for this measurement.

Measurement purpose

When installing an EV fast charger, high power conversion efficiency means less energy loss. For example, if the specifications of the charger specify that the power conversion efficiency is 95%, this means that 95% of the AC power supplied from the grid is converted to DC power for the charging process.

Sometimes, even though the specifications for the fast EV charger are rated at 95% on paper, the measurement result on-site could say something different. For example, if the power efficiency measurement result on-site was 70%, meaning that 30% of the power is wasted during the conversion process. This will result in a longer charging time for the consumer as well as substantially higher electricity bills for the owner of the EV charger. It is a no-win situation for both the consumer and the owner of the charger. Therefore, measuring the power conversion efficiency on-site is essential to ensuring that the EV charger performs in line with the manufacturer's requirements and may serve as proof that the charger selected by the owner is an excellent investment.

Example of conducting EV fast charger on-site efficiency measurement

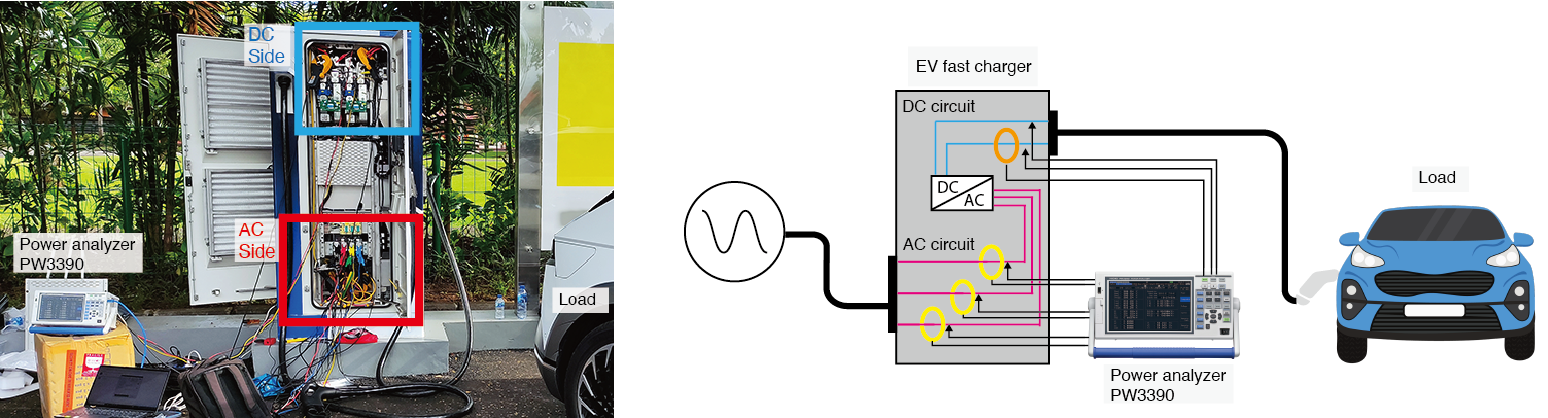

The measurement method may vary in different countries or with the charger's installer, but here is an example of how a fast EV charger power efficiency conversion was conducted on-site for one of Hioki's partners. During the installation process, an EV, which served as a load, was charged using the charger. A Hioki power analyzer recorded the measurement data. Figure 1 shows an example of how the connections were made. To conduct the measurement, the fast charger's housing was opened. The connections were then made between the charger's circuit panel and the instrument, on the grid side (three-phase AC) and the converted DC side. The duration of measurement varied, ranging from 15 minutes to an hour, depending on the vehicle type and its state of charge (SOC).

Fig. 1 Hioki's partner measuring EV fast charger's power efficiency

Table 1 shows an example of measurement parameters, together with the purpose and challenges of those measurement parameters faced by the installer. Take note that the parameters might differ according to the country's regulations, the EV charger's installer, and the owner's preferences.

Table 1: Measurement parameters, purposes and challenges.

| Parameters | Purposes | Challenges |

|---|---|---|

| Power, voltage, current, AC to DC power conversion efficiency, power factor | To check the charging capacity, power conversion efficiency, and specifications correctness. |

|

| Harmonics and THD |

| High frequency bandwidth measurement capability to capture harmonics and supraharmonics compenents |

| DC ripple voltage and current |

|

|

To perform on-site measurements effectively, the power analyzer selected for this application should be portable and convenient to carry. In the field, the installer records the measurement results, which are then presented to both the owner and the utility service provider. This data serves as proof that the installation was done correctly and also did not cause any harm to the power supply side.

Hioki's on-site EV fast charger power efficiency measuring solutions

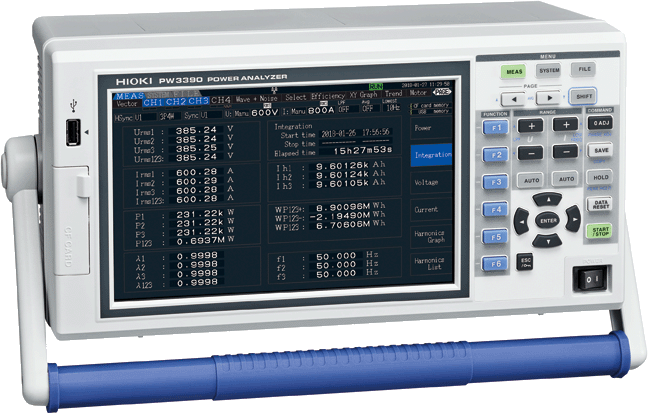

To conduct power efficiency measurements on-site for an EV fast charger, Hioki recommends the power analyzer PW3390. Here are three key points that highlight why the PW3390 is the best tool for this application:

- 1.Unsurpassed precision in a compact form

- 2.Wide-band measurement compability

- 3.Instant and effortless report generation

1. Unsurpassed precision in a compact form

Due to its portability and the ability to conduct power measurement accurately on-site, the PW3390 is ideal for this application. Table 2 shows an overview of the specifications for the PW3390.

Table 2: Overview of the specifications for the PW3390

| Items | Basic specifications |

|---|---|

| Channels | 4 channels, perfect for simultaneous AC 3-phase and DC power efficiency measurement. |

| |

| Power measurement range | 1.5000 W to 90.00 MW |

| Voltage measurement range | 15 to 1500 V, 7 ranges |

| Current measurement range | 0.1 A to 20 kA (depends on current sensor) |

| Dimensions and weight | 340 mm (13.39 in.) W × 170 mm (6.69 in.) H × 156 mm (6.14 in.) D, 4.6 kg (162.3 oz.) |

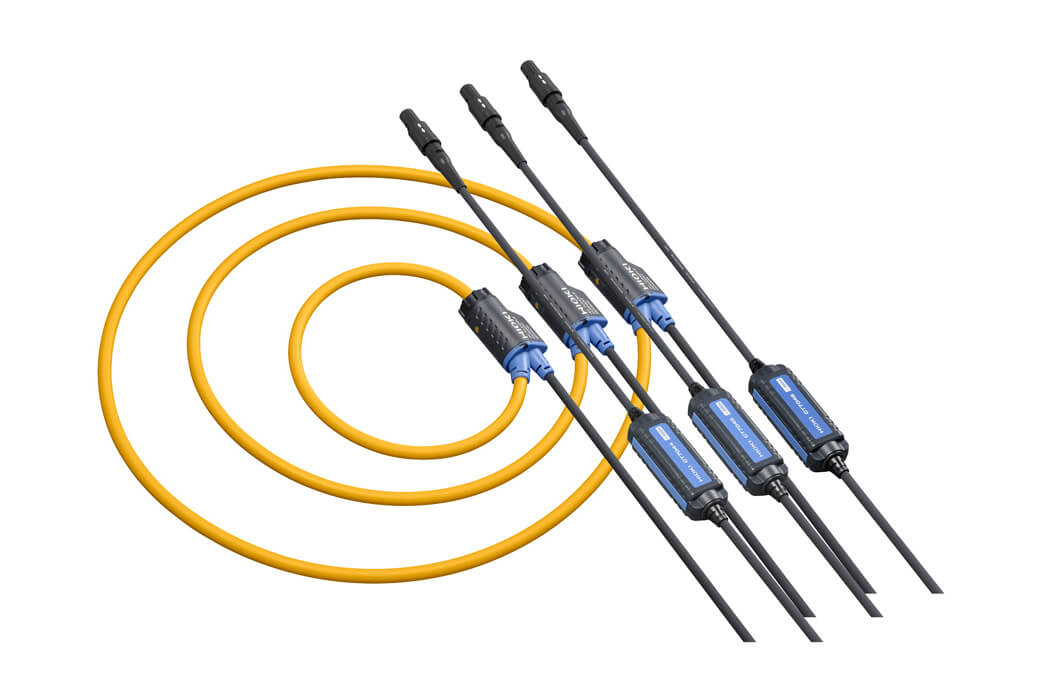

Not to forget, the PW3390 adopts the clamp sensor method for current measurement. For this particular application, we would recommend the AC/DC current probe CT6845A, as its measurable conductor size is up to 50 mm in diameter and the measurable current is up to 500 A. Using the clamp sensor method for this application makes on-site measurement much easier and enables high-current measurements to be done accurately over a wide operating temperature range.

Other than the mentioned clamp sensor, Hioki also offers a wide range of AC and AC/DC current sensors of different sizes and current ranges. (See Table 3)

Table 3. Other recommended current sensors for charger testing

| Current sensor | Diameter of measurable conductor | Rated current |

|---|---|---|

| AC Flexible Current Sensor CT7045(*1) | φ 180 mm (7.09 in.) | 6000 A AC |

| AC/DC Current Probe CT6843A | Max. φ 20 mm (0.79 in.) | 200 A AC/DC |

| AC/DC Current Probe CT6844A | Max. φ 20 mm (0.79 in.) | 500 A AC/DC |

| AC/DC Current Probe CT6846A | Max. φ 50 mm (0.79 in.) | 1000 A AC/DC |

- *1:Conversion cable CT9920 is needed

2. Wide-band measurement compability

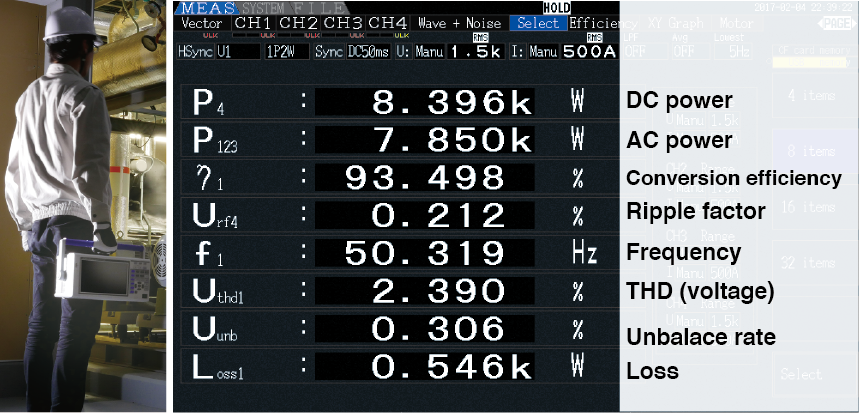

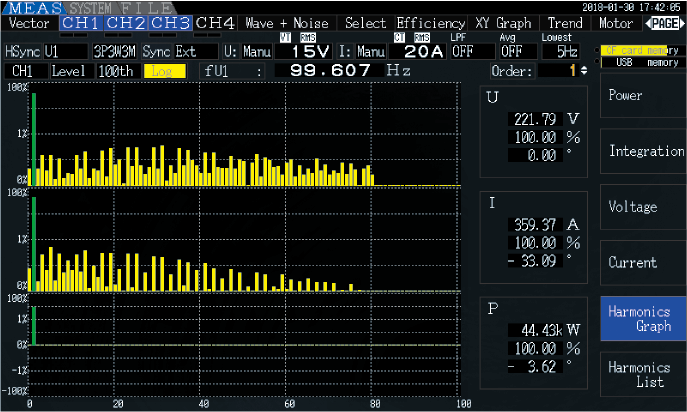

The PW3390 features FFT function analysis that covers a wide range from DC to 200 kHz. This capability enables the analysis of harmonics, supraharmonics, and THD measurements up to the 100th order. Additionally, the wide-band measurement capacity extends to the assessment of DC ripple voltage and current, making it suitable for measuring the ripple current of EV fast chargers within the 200 kHz range, aligning with relevant standards.

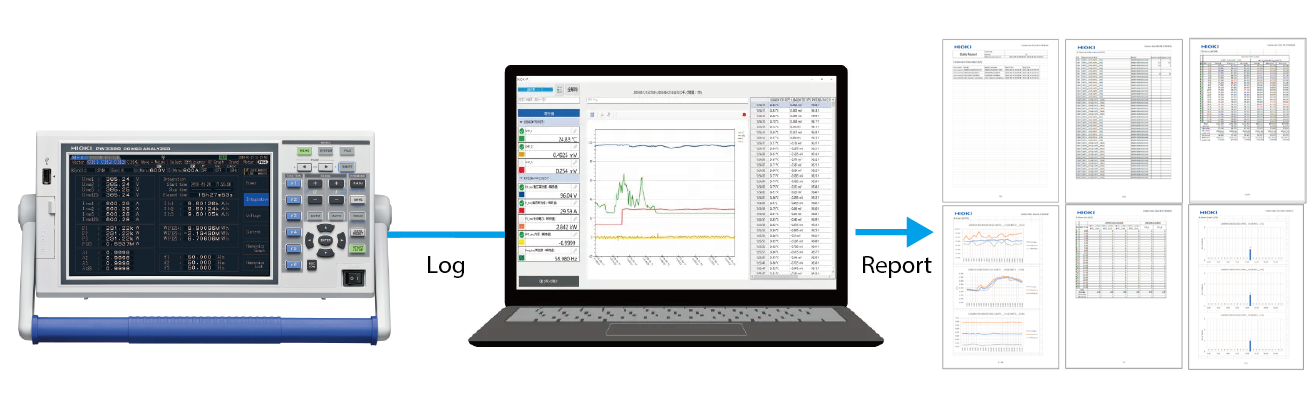

3. Instant and effortless report generation

GENNECT One (free software) allows for easy data collection from the PW3390. The software lets you log the measurement data so that you can observe the measurement trends in real time. You can also record the measurement data and instantly generate a report that can be presented to the owner and utility company as evidence that the installation was performed correctly and did not result in power quality issues.

Finally

With the increasing focus on EVs from the perspective of environmental protection, the power efficiency of fast chargers is an important measurement and evaluation criteria that is indispensable for furthering the use of EVs. Hioki's power analyzer PW3390 and the clamp sensors are the best measuring devices for on-site EV fast charger measurement due to their portability, electrical performance, and ease of report creation. Check the PW3390 product page or speak with our specialist for additional product information.