Efficiency and loss evaluation of SiC inverters

The challenge of evaluating the efficiency and loss of SiC (Silicon Carbide) inverters

Realizing more accurate measurement with Hioki products

Featured customer

Company S is a manufacturer of household appliances that boasts some of the highest sales of any company in the industry worldwide. The company develops products and parts at facilities in Japan and supplies household appliances to various countries worldwide. In recent years, it has focused on developing energy-efficient appliances, and its products deliver unsurpassed energy-saving performance.

Background

Company S needed a system that could accurately evaluate the efficiency and loss of SiC inverters.

Manufacturers throughout the appliance industry are working to increase the energy-saving performance of appliances such as air conditioners, refrigerators, and washing machines. No exception to this trend toward developing higher-performance, more energy-efficient products, Company S has worked to increase the energy-saving performance of inverters and motors that it develops in house. As part of the effort to further reduce power consumption and shrink high-performance products, the company adopted a policy of using next-generation silicon carbide (SiC) inverters in its products. These inverters have low loss despite switching at high frequencies, and they make a significant contribution to smaller product sizes. Going forward, the industry-wide move to SiC inverters is set to accelerate as a stable supply of low-cost SiC power devices becomes available.

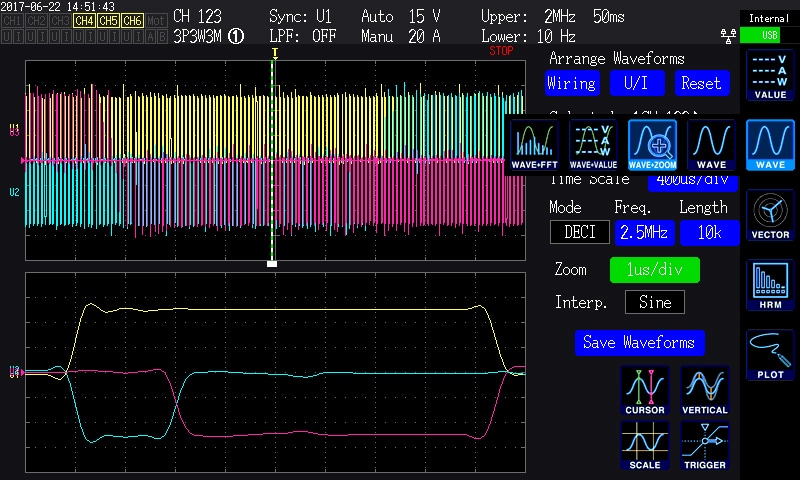

Switching waveform

Switching waveform

However, SiC inverters are more difficult to evaluate quantitatively because they have low loss despite their high-frequency switching operation. It is difficult to accurately measure the efficiency and loss of SiC inverters with the power analyzers and current sensors that have conventionally been used to evaluate inverter efficiency. To make progress in development, the ability to accurately measure power conversion efficiency is essential. When Company S measured the SiC inverters it had developed after calculating how much of an improvement a switch to a given part could be expected to yield during the design phase, it found a significant divergence between those expected values and the actual measured values, prompting doubts about whether the evaluations it had conducted in the past had been accurate. As a result, the company began considering purchasing a new measurement system that could accurately evaluate SiC inverters.

Key considerations that led the customer to choose Hioki

Ability to measure the efficiency of SiC inverters and to make accurate measurements at a variety of switching frequencies

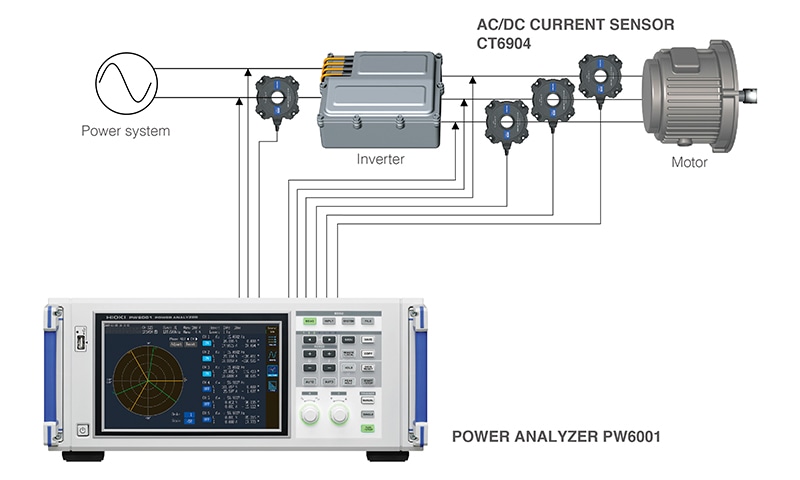

Measure the Power Conversion Efficiency of Inverters

Measure the Power Conversion Efficiency of Inverters

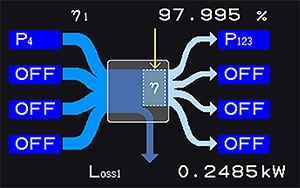

The power conversion efficiency of SiC inverters easily exceeds 95% these days, and manufacturers are refining their designs in the pursuit of figures beyond 99%. Consequently, an increase of just 0.1% is a significant improvement, and an error of 0.1% in measurements results will have a substantial impact on subsequent development. Similarly, the company needed a system that could accurately measure the remaining percentage of loss.

Company S had been using power analyzers and current sensors from another company, but for this purchase it undertook a comparative study of measurement systems based on their ability to accurately measure SiC inverters. The company also emphasized the performance that would be needed to accurately measure efficiency and loss at even higher switching frequencies in the future.

As a result of that process, the company chose Hioki as its partner for the system because Hioki has groups of products with the broad frequency band, high noise resistance, and high measurement accuracy needed to accurately measure SiC inverters, and because Hioki’s experience developing, manufacturing, and selling both power meters and current sensors means it can provide accurate measurement systems in optimal configurations. After actually measuring the efficiency of a prototype SiC inverter it had built, the company decided to purchase the Power Analyzer PW6001 and the AC/DC Current Sensor CT6904, which it found yielded the expected efficiency and loss figures at a variety of switching frequencies.

Efficiency and loss calculations

Efficiency and loss calculations

The decision was made after discussions between the two companies yielded a compelling technical explanation for the inability of conventional power analyzers and current sensors to make accurate measurements. This approach was an important process for Company S.

Benefits

Accurate measurement of SiC inverters and fine-tuning optimal operating conditions

Power Analyzer PW6001

Power Analyzer PW6001 AC/DC Current Sensor CT6904

AC/DC Current Sensor CT6904

By purchasing the Power Analyzer PW6001 and AC/DC Current Sensor CT6904, Company S gained the ability to accurately measure SiC inverters and to evaluate the results of development in the form of improved performance in metrics such as power conversion efficiency and loss. Compared to the company’s previous system, the new system’s power conversion efficiency measured values differ from the previous system’s by several percentage points, and its loss values differ by a factor of 4. Additionally, the new system helps smooth adjustment work when fine-tuning optimal operating conditions.

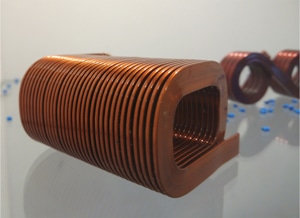

Company S is considering using the system in applications other than SiC inverter measurement, for example in measuring the power loss of high-frequency reactors installed in circuits. Since the high switching frequency used by circuitry surrounding the reactors makes accurate measurement difficult, the company is planning to use the Power Analyzer PW6001 and AC/DC Current Sensor CT6904, which provide exceptional high-frequency measurement capability, to measure loss in that application.

Reactor

Reactor

If the company develops products with large SiC devices in the future, it will be able to measure power conversion efficiency and loss of a variety of components simply by switching current sensors since Hioki offers a selection of current sensors with excellent measurement accuracy, noise resistance, and wideband performance (DC to 1 MHz) for currents up to 2000 A. Company S appreciates the ability to use the system in a variety of applications while limiting capital investment.

The new system promises to help the company launch products with some of the highest energy-saving performance in the world.