Lithium-ion Battery Open-circuit Voltage (OCV) Testing

What is open-circuit voltage (OCV) testing of lithium-ion batteries?

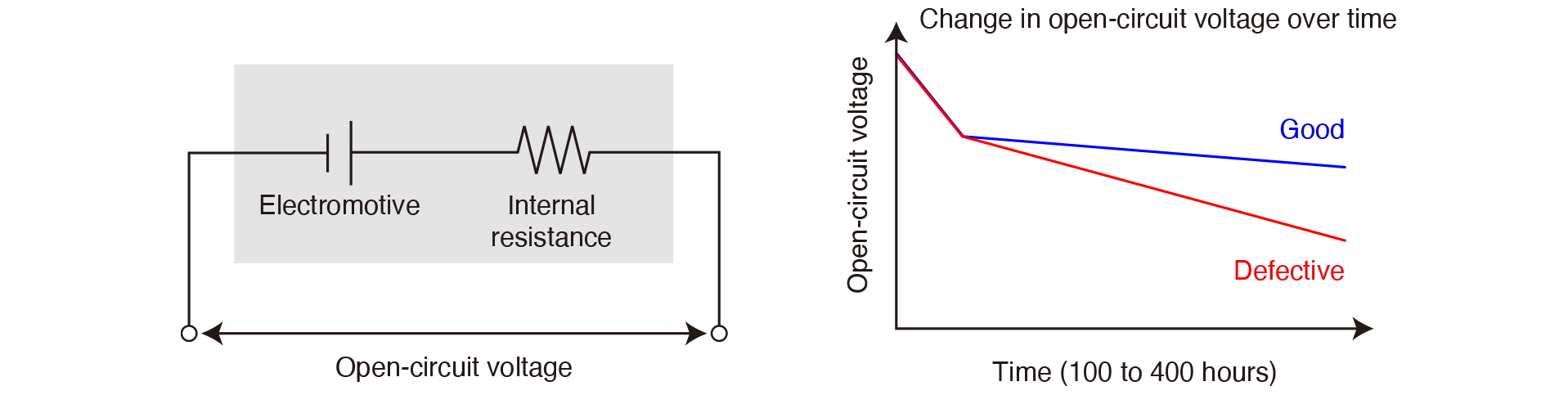

On production lines that manufacture cells for lithium-ion batteries, OCV testing plays a key role in detecting defects. OCV is a battery’s voltage when it is not connected to any load. Batteries exhibit self-discharge characteristics, which causes their OCV values to decline gradually over time. When a battery has an internal defect, self-discharge increases. On production lines, testing serves to detect batteries whose OCV has decreased beyond the defined value so that they can be excluded as defective.

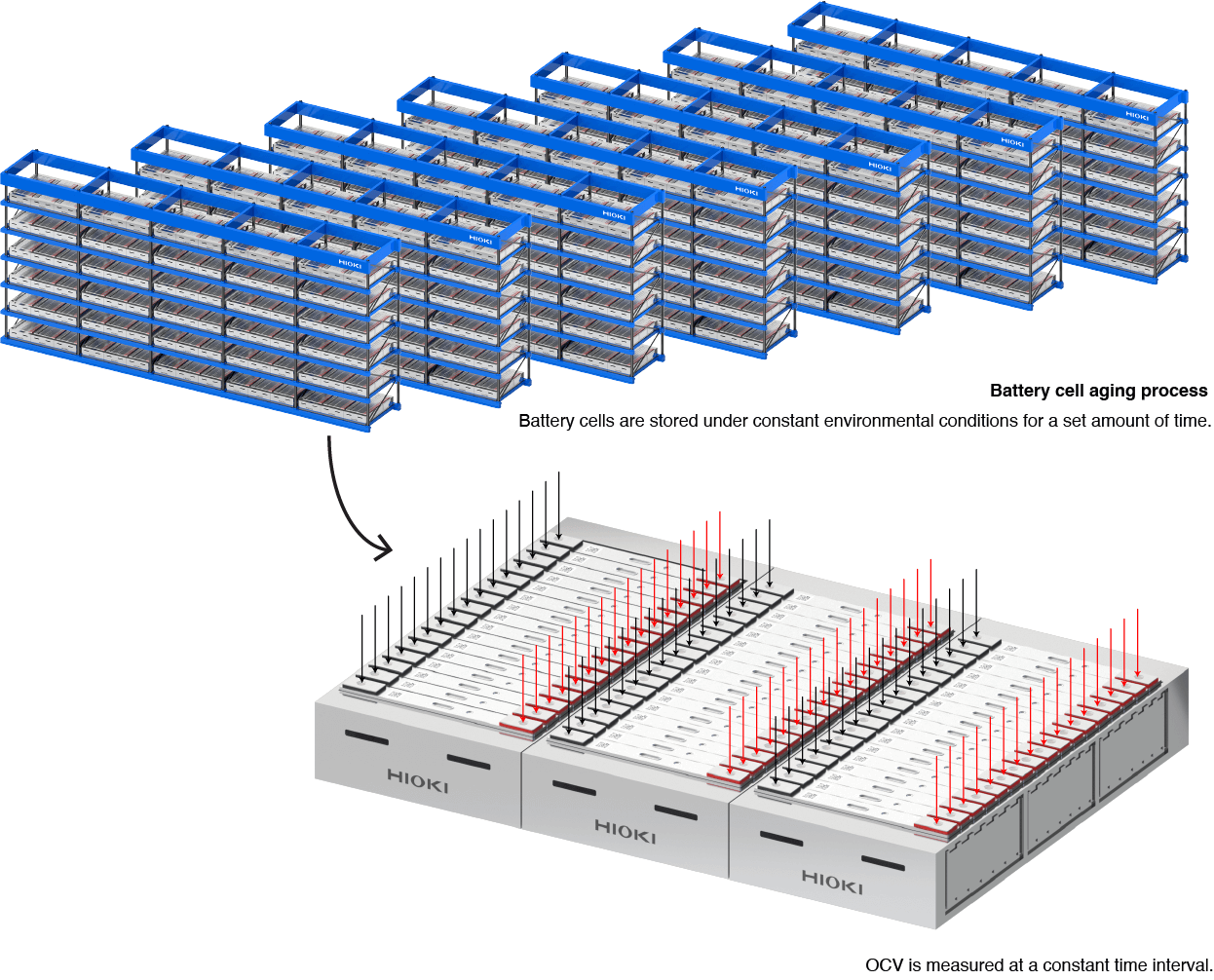

When to test Open-circuit Voltage (OCV)

Manufacturers carry out the OCV testing in each process after initial charging. Notably during the aging process, OCV should be measured at a constant time interval with high accuracy, to evaluate its small change due to self-discharge. It requires generally 100 to 400 hours to detect defective cells.

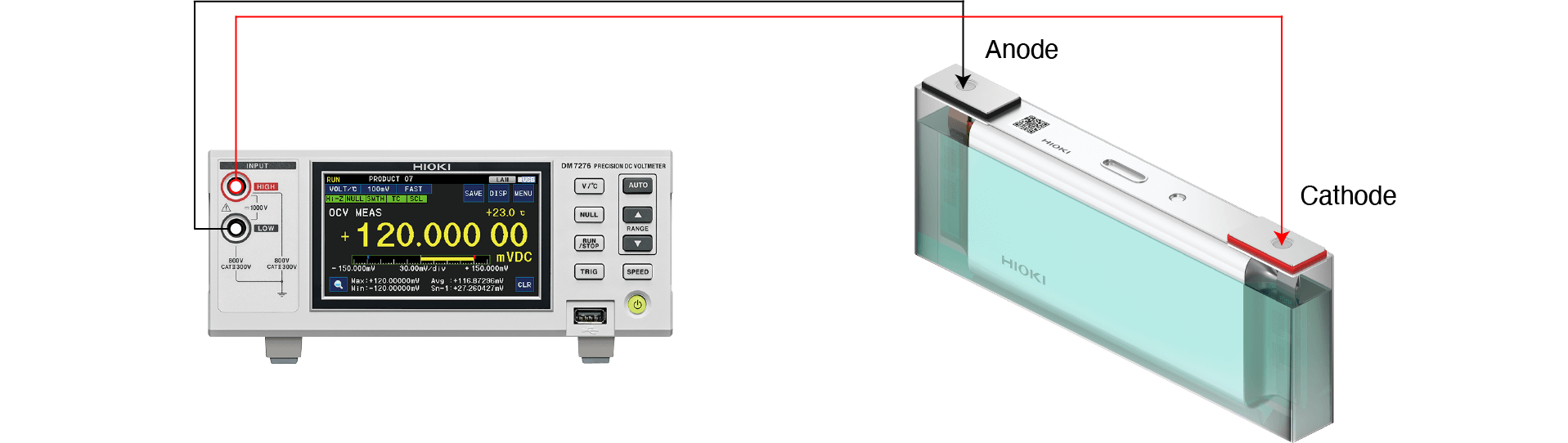

How to measure Open-circuit Voltage (OCV)

A DC voltmeter is used to measure battery cells’ OCV. The voltmeter detects the voltage between battery cells’ positive and negative electrodes.

Key considerations when choosing a DC voltmeter

The following considerations should be borne in mind when choosing a voltmeter:

- Resolution

- Accuracy calculations

- Temperature compensation function

Resolution

On battery cell production lines, defects are detected based on miniscule differences in OCV readings. Using a high-resolution DC voltmeter makes it possible to detect defective cells sooner, shortening testing times.

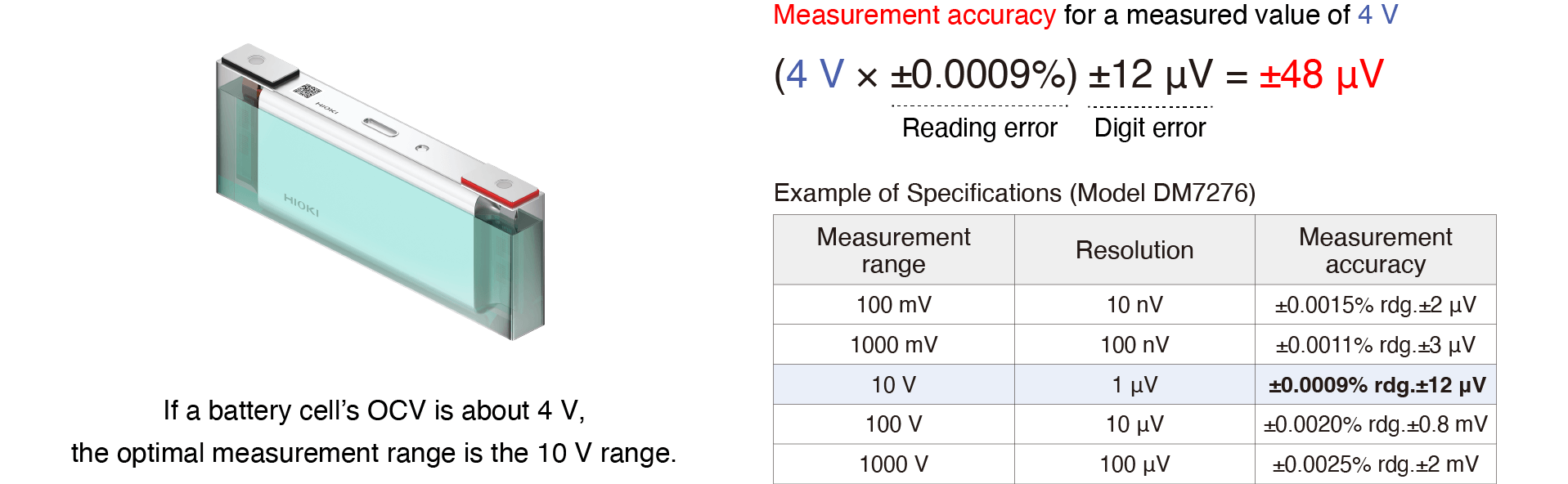

Accuracy calculations

Accuracy calculations are key accurately understanding instrument performance. Most instruments define accuracy in terms of reading error and digit error.

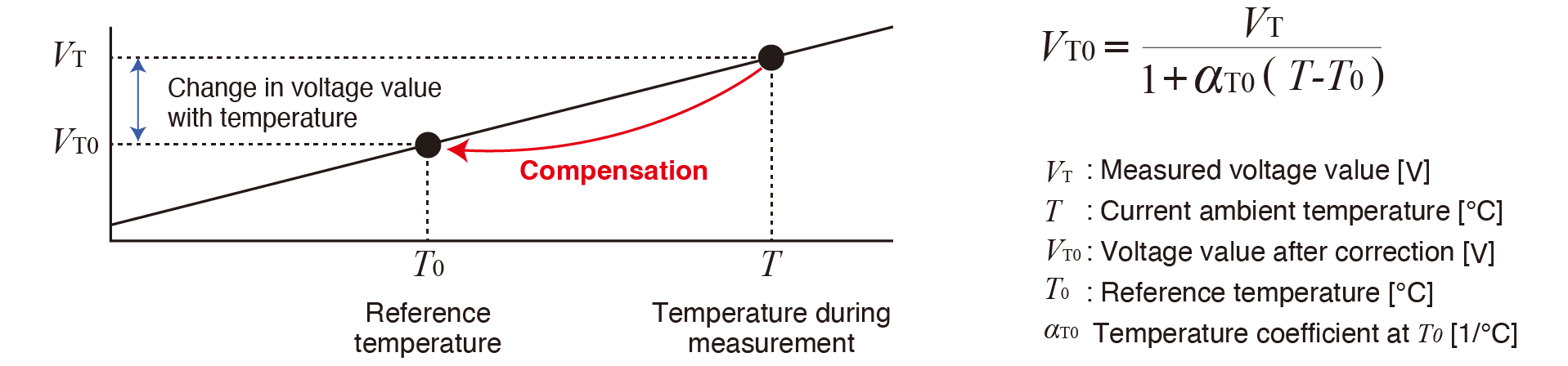

Temperature Compensation Function

Batteries’ OCV varies with temperature. A change of just 1°C in temperature at the time of measurement can cause the OCV value to change by several hundred microvolts. It’s important to keep the temperature environment constant during measurement. Instruments’ temperature compensation function converts measured values to voltage values at a reference temperature.

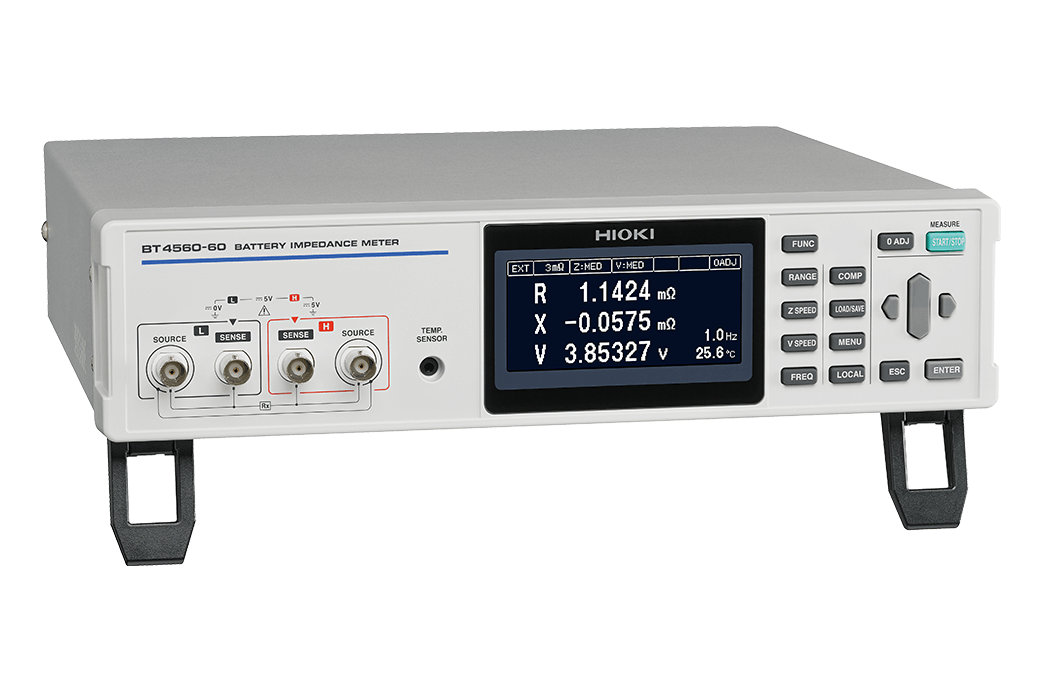

DC Voltmeters from Hioki

Hioki’s DC Voltmeters are used by battery manufacturers around the world. The following models are used in OCV testing in battery cell production processes.

| Product model | DM7276 | BT4560-50 BT4560-60 | BT3561A | BT3562A |

|---|---|---|---|---|

| Number of digit | 7 1/2 digit, 12.000 000 | 5 1/2 digit, 5.100 00 | 5 1/2 digit, 6.000 00 | 5 1/2 digit, 6.000 00 |

| Measurement range/Resolution | 120.000 00 mV/ 10 nV | 5.100 00 V/ 10 μV (*1) | 6.000 00 V/ 10 μV (*1) | 6.000 00 V/ 10 μV (*1) |

| 1200.000 0 mV/ 100 nV | —/— | 60.000 0 V/ 100 μV | 60.000 0 V/ 100 μV | |

| 12.000 000 V/ 1 μV (*1) | —/— | —/— | 100.000 V/ 1 mV | |

| 120.000 00 V/ 10 μV | —/— | —/— | —/— | |

| 1010.000 0 V/ 100 μV | —/— | —/— | —/— | |

| Basic accuracy (*2) | ±0.0009% rdg ±12 μV | ±0.0035% rdg ±5 dgt | ±0.01% rdg ±3 dgt | ±0.01% rdg ±3 dgt |

| Measurement error (*2) | ±48 μV | ±190 μV | ±430 μV | ±430 μV |

| Temperature compensation function | ✔ | — | — | — |

| Temperature measurement | ✔ | ✔ | — | — |

| Battery internal resistance measurement (*3) | — | ✔ | ✔ | ✔ |

- *1:When using recommended range for 4 V measurement.

- *2:Measurement accuracy and measurement error values apply to measurement of 4 V lithium-ion batteries in the 4 V measurement recommended range.

- *3:The BT3561A, BT3562A, and BT4560 series can simultaneously measure both OCV and internal resistance.