Unlock Insights by Using Hioki’s Memory HiCorder MR6000 for Motor Bench Analysis

Craft vibration and noise countermeasures more efficiently by simultaneously measure torque ripple, phase current, and induced voltage!

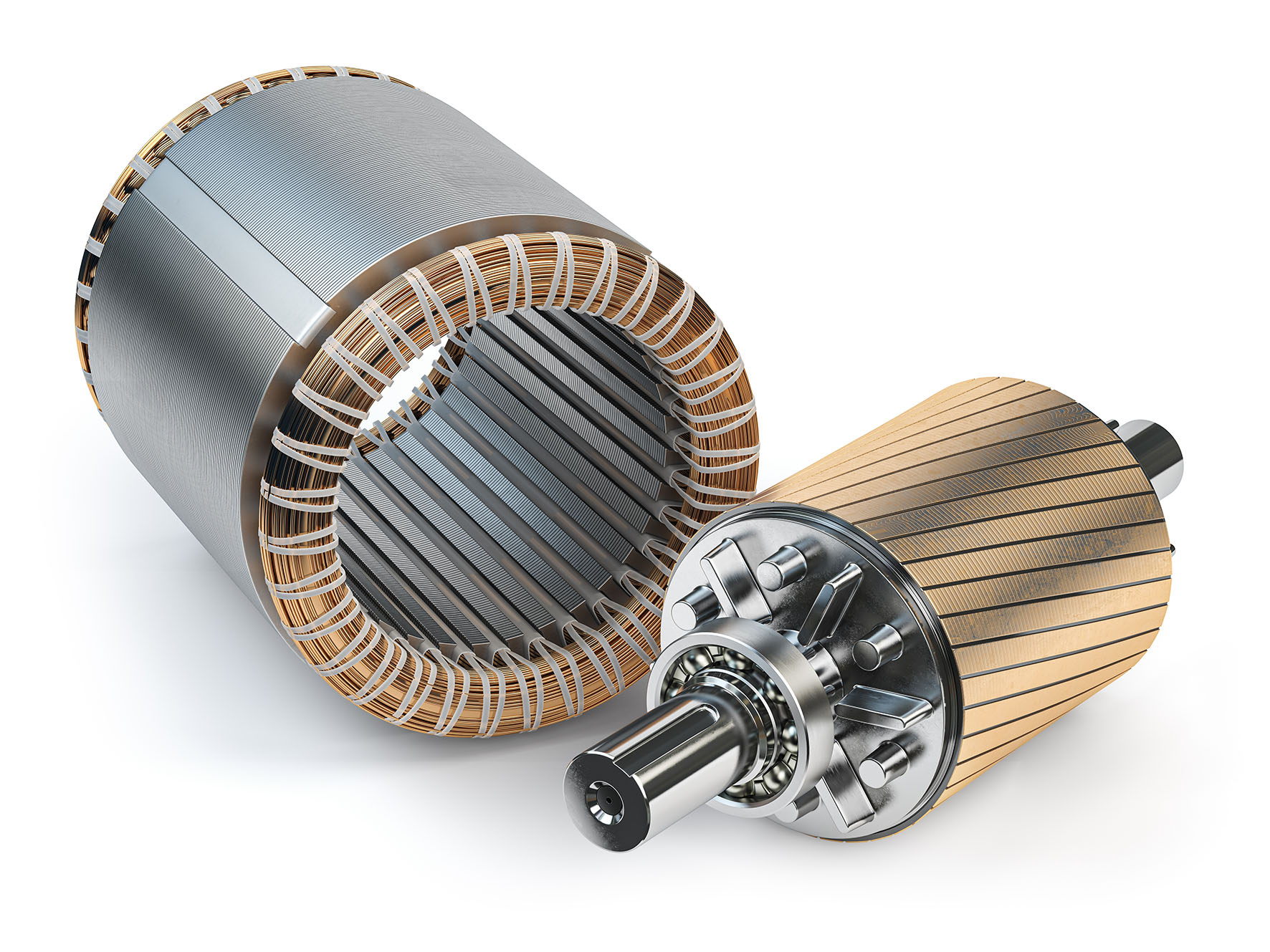

In recent years, motors used in EVs and other automobiles have been called upon to deliver ever-higher levels of quality. For example, if a power steering motor exhibits torque ripple, that could cause the steering wheel to vibrate when the driver is steering the vehicle, creating an unpleasant sensation. Since motor torque ripple can cause noise and vibration, manufacturers implement a variety of countermeasures and conduct research to reduce it.

Torque ripple occurs for many reasons, and as engineers seek techniques for controlling it, for example by modifying the structural design of motors and implementing various control technologies, the ability to measure and evaluate torque ripple promises valuable clues and insights.

This Application Note introduces measurement methods that offer such insights concerning motor noise and vibration countermeasures. It also presents example measurements made with the Memory HiCorder MR6000.

Have you experienced these issues in regard to motor vibration and noise countermeasures?

- You've controlled torque ripple, but it’s unclear whether that’s actually serving to reduce vibration and noise.

- You want to measure electric signals (phase current or induced voltage) at the same time as vibration and torque ripple, but it's cumbersome and/or costly to have multiple instruments.

- Your application requires a large number of instruments, and preparing for measurement has become a daunting task.

◤ Hioki has solutions!

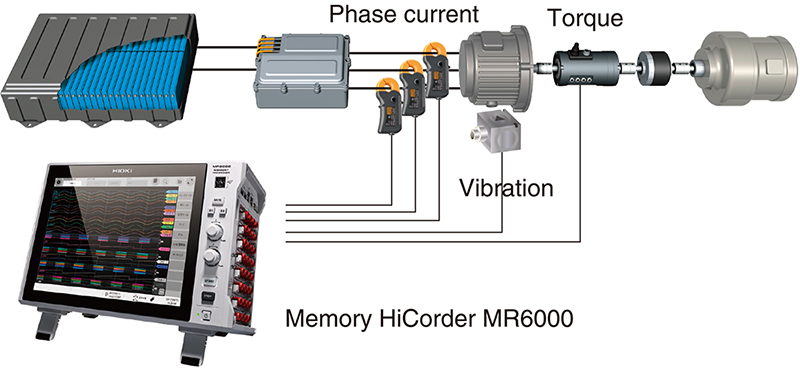

Hioki’s Memory HiCorder MR6000 can be used with an array of input modules to observe numerous phenomena, including vibration, torque ripple, phase current, and induced voltage, all on a single time axis. Reviewing the correlations among phenomena and performing FFT analysis by simultaneously measuring a large number of phenomena can help pinpoint the causes of motor vibration and noise.

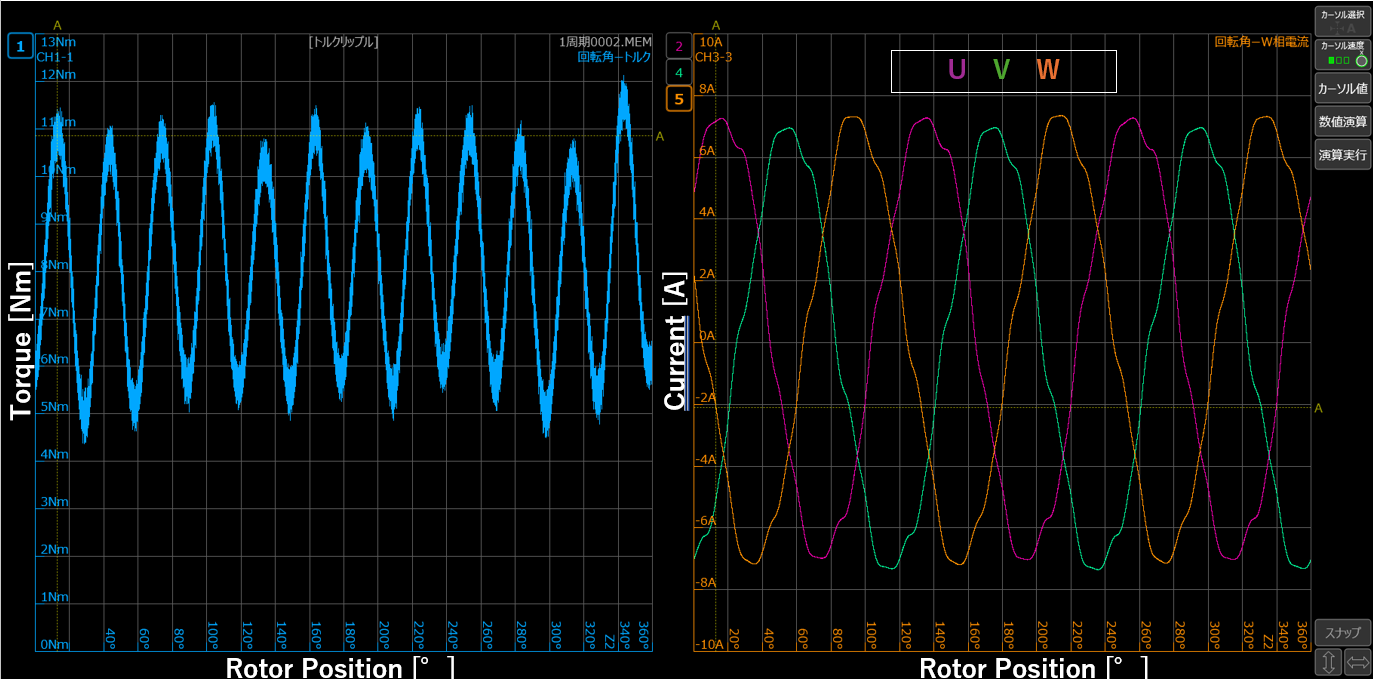

Observed IPSM torque ripple and phase current waveforms

◤ Observing correlation between rotation angle and torque/phase-current

You can evaluate correlations between motor torque ripple, vibration, and electrical parameters (phase current, induced voltage, motor efficiency, etc.,) by combining the rotation angle measurement function (output from a resolver or rotary encoder) with the instrument’s X-Y graph function.

Parameters that can be measured or evaluated

- Measure and evaluate electrical angle, mechanical angle, one-cycle torque ripple, vibration, phase current, and induced voltage.

- Evaluate torque ripple rate using the waveform calculation function.

FFT analysis to evaluate correlation between vibration, torque, and phase current

RPM: 400 rpm; carrier frequency: 10 kHz

In this example, the waveforms indicate that torque ripple peaks at the 12th order (240 Hz component) as a result of the motor being energized with a fundamental frequency of 20 Hz. It also indicates that the torque ripple is causing vibrations that peak at 240 Hz. In this way, a single MR6000 can evaluate torque ripple caused by phase current and the resulting vibration. If you’re considering methods of reducing torque ripple such as the application of harmonic current, it can be effective and useful to simultaneously analyze phase current, torque ripple, and vibration in this way.

Parameters that can be measured or evaluated

- Evaluate the correlation between vibration and torque ripple caused by coil energization.

- Simultaneously analyze vibration and noise conditions along with the torque ripple and phase current causing them.

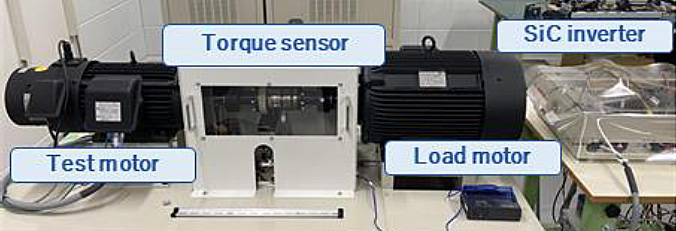

Measurement environment

HiCorder MR6000 used in analysis on a motor bench

The Memory HiCorder MR6000 is a waveform recorder that can perform high-speed sampling at up to 200 MS/s and record data across a large number of channels over an extended period of time. Thanks to an extensive selection of input modules, you can use a single instrument to simultaneously measure parameters like phase current, torque, and vibration with a combination of modules in motor bench analysis applications that in the past have required multiple instruments. Furthermore, you can perform frequency analysis of captured signals using the MR6000’s FFT analysis function.

Measurement parameters and functions

- Rotation angle measurement

- Vibration measurement using a charge amplifier

- Multichannel torque ripple measurement and simultaneous measurement of induced voltage, phase current, and other parameters

- Calculation of the torque ripple rate using the instrument’s waveform calculation function

- FFT analysis function

- X-Y graph function

| Product name | Manufacturer | Application |

|---|---|---|

| MEMORY HiCORDER MR6000 | Hioki | Recording and analysis |

| 4CH ANALOG UNIT U8975 | Hioki | Rotation angle measurement |

| CHARGE UNIT U8979 | Hioki | Torque and vibration measurement |

| 3CH CURRENT UNIT U8977 | Hioki | Current Measurement |

| AC/DC CURRENT PROBE CT6841A(20A)/CT6843A(200A) | Hioki | Phase current measurement |

| Acceleration pickup | Non-Hioki | Vibration measurement |

| Torque sensor | Non-Hioki | Torque measurement Band: 6kHz |

*Customer must provide acceleration pickup, torque sensor, and microphone.