Thermal Runaway & Propagation Testing for Battery Safety

Verifying Thermal Propagation in Lithium-ion Batteries During Thermal Runaway Events

Lithium-ion batteries used in electric vehicles (EVs) can experience internal shorts caused by manufacturing defects or damage from impact. Batteries with an internal short can heat rapidly, posing a risk of a thermal runaway event. This thermal runaway is very dangerous. It is a state in which a battery-cell’s heating causes more and more heating and reaches a point where it cannot be stopped. A thermal runaway event in one cell can progress or “propagate” into a chain reaction to adjacent cells, causing the entire battery system to catch fire. A variety of international standards have been enacted to prevent this phenomenon. That is why, as part of design verification and certification testing, manufacturers are required to evaluate how heat from a thermal runaway event is propagated. This application note introduces a solution in which a Hioki data logger is used in thermal propagation testing.

What is thermal propagation testing?

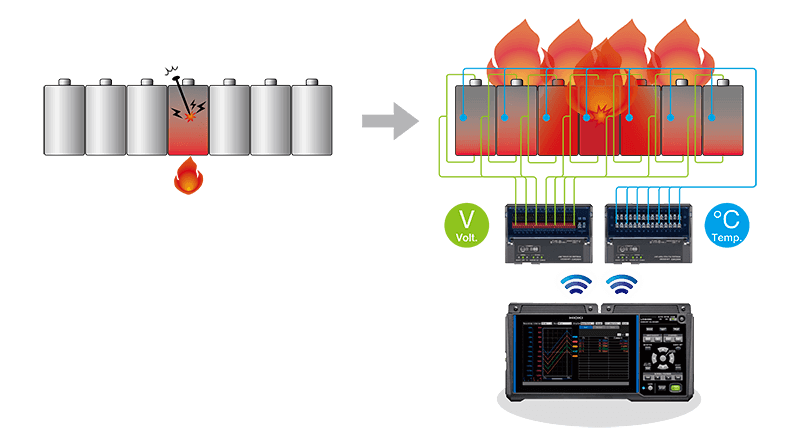

In this test, a single cell is heated or exposed to a mechanical impact by means of nail penetration in order to induce a thermal runaway event in the cell. By inducing the abnormal heating of the battery, the effect of a thermal runaway event on the battery system can be verified. The thermal propagation process is verified by measuring each cell’s voltage and temperature as heat from the thermal runaway event propagates to nearby cells. Some standards impose quantitative judgment criteria for changes in temperature and voltage, and thus require that measured values be recorded.

Measuring instruments required for thermal propagation testing

Since thermal propagation testing of batteries is a destructive test, it’s difficult to perform repeatedly from a cost standpoint. This necessitates the use of a data logger that can reliably acquire all necessary data during a single test. In addition, testing imposes risks associated with contingencies such as the heating and possible combustion of the battery, making it necessary to take steps to ensure the engineer’s safety.

All of the aforementioned points result in the following requirements for the test:

· Ensuring the engineer’s safety

· Simultaneously measuring each cell’s temperature and voltage as well as deformation of the package caused by heat

· Evaluating BMS (Battery Management System unit) behavior during the thermal runaway event

· Measuring voltage fluctuations in battery cells at a high sampling speed

Hioki data loggers can be used to perform safe, reliable testing

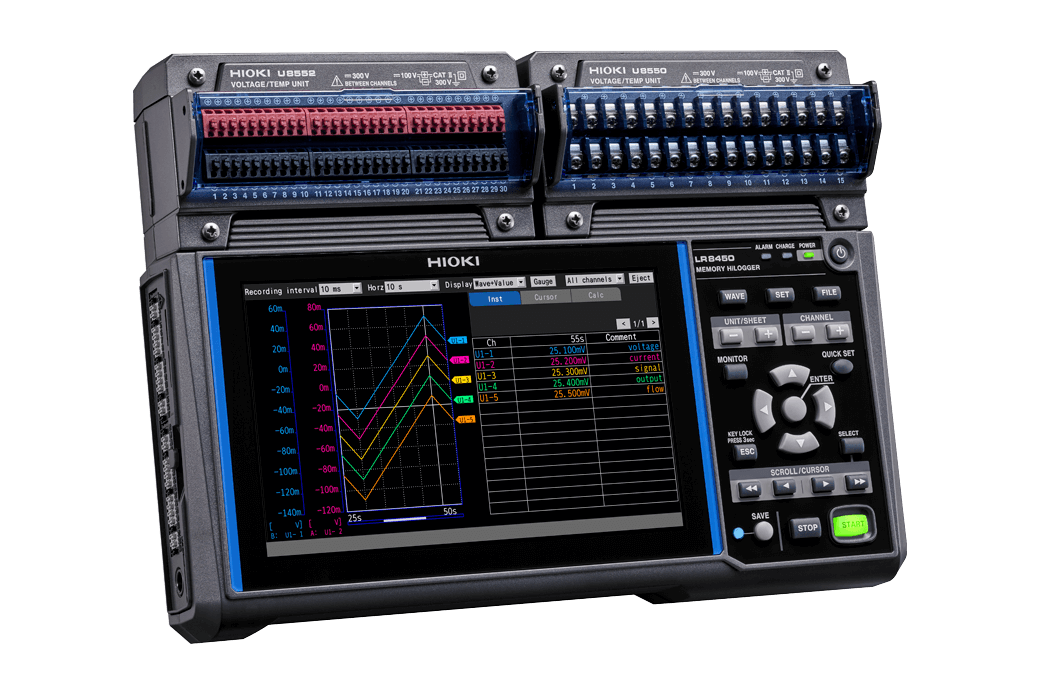

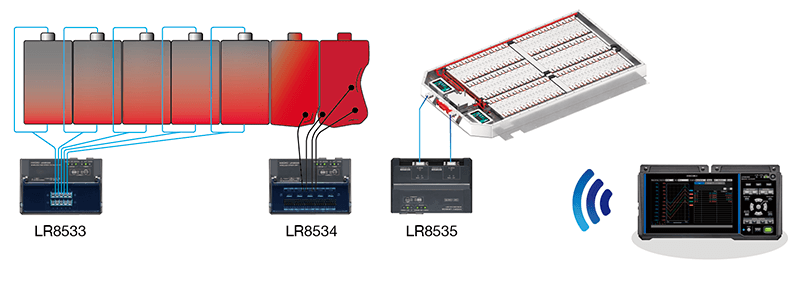

Hioki’s Data Logger LR8450-01 is well suited to recording voltage and temperature data during battery thermal propagation testing. The LR8450-01 is equipped with a display and is used with optional measurement modules. It can wirelessly acquire data measured by remotely positioned modules. In this way, it allows testing associated with risks such as fire to be reviewed in real time and from a safe location. An extensive lineup of measurement modules is available, allowing the instrument to simultaneously measure a variety of parameters. Up to 4 plug-in measurement modules and 7 wireless measurement modules can be used with a single logger. Consequently, the LR8450-01 can measure up to 330 channels and record data, making it, yet again, ideal for measuring every cell in a battery module.

The LR8450-01 is recommended for thermal propagation testing of batteries for two reasons:

1. Safe testing via wireless data collection and alert functionality

2. Simultaneous data integration of hundreds of channels from an extensive lineup of measurement modules and their various measurement parameters

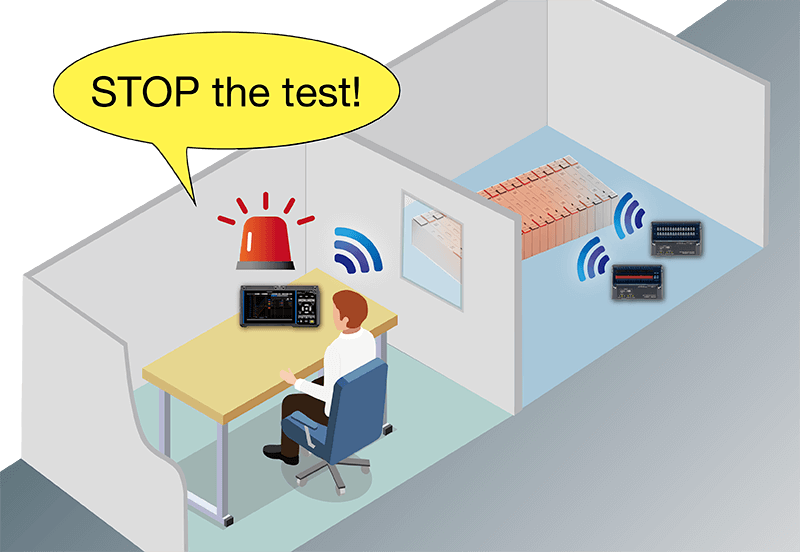

1. Safe testing via wireless data collection and alert functionality

Since data can be collected wirelessly, the logger and measurement modules can be positioned far apart. Measurement modules can be placed in a lab, while the logger itself is operated from a safe, remote location to observe data. In this way, it allows testing associated with risks such as fire to be reviewed in real time from a safe location. Furthermore, the logger can output alarm signals. For example, if you set up an alarm signal to output in the event the temperature rises abruptly, you can get notified and stop testing before the device under test reaches a dangerous state.

2. Simultaneous data integration of hundreds of channels from an extensive lineup of measurement modules and their various measurement parameters

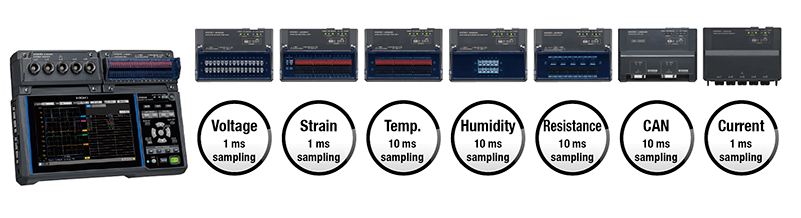

An extensive lineup of measurement modules that support various parameters is available for the LR8450-01. Different parameters can be measured and recorded simultaneously across a large number of channels.

| Product name | Model name | Role in thermal propagation test |

|---|---|---|

| Wireless Voltage/Temp Module | LR8532 | Observe fluctuations in individual cells’ temperature and voltage |

| Wireless High Speed Voltage Module | LR8533 | Observe voltage fluctuations at high speed with a 1 ms sampling interval |

| Wireless Strain Module | LR8534 | Observe package deformation caused by heat |

| Wireless CAN Module | LR8535 | Evaluate BMS behavior during a thermal runaway event by simultaneously logging CAN output from the BMS. |

Summary

Hioki’s LR8450-01 data logger and its extensive range of measurement modules can help conduct safe and reliable thermal propagation testing of batteries. It’s important to assess the thermal propagation process and provide feedback about thermal propagation countermeasures to the battery pack developers. This solution lets you observe fluctuations in individual cells’ temperature and voltage and make comprehensive evaluations that also take into account BMS behavior and package deformation caused by heat. Please visit the LR8450-01 product page for more information about this product.

Requests for demonstration units and questions about applications should be directed to your closest Hioki sales representative through our contact page.