Measurement of Leakage Current in EV Power Management

Measurement of Leakage Current in EV Power Management

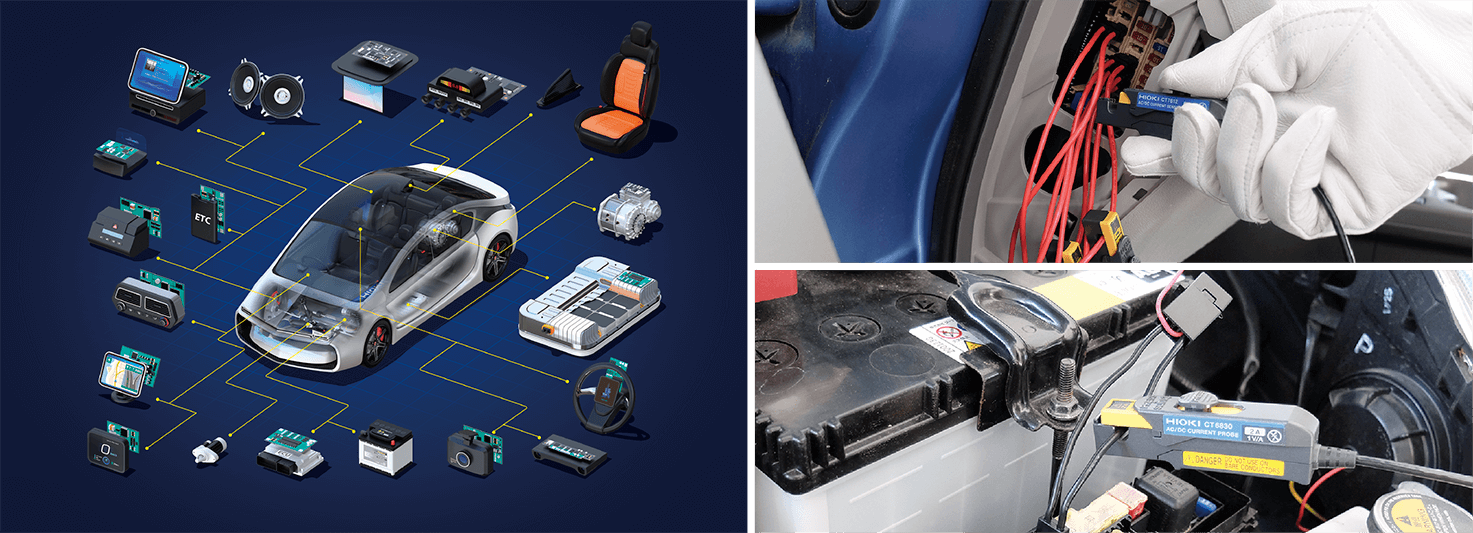

In the domain of e-mobility, especially electric vehicles (EV), range extension is one of the most important priorities. To boost range, it’s important to measure power consumption and leakage current not only for batteries and powertrains, which use a large amount of power, but also for devices such as ECUs and electrical accessories. This application note introduces a solution for measuring current consumption and dark current for a variety of devices, including ECUs and electrical accessories, in fully finished EVs using a Hioki data logger and using that data in overall vehicle power management.

Necessary measurement tasks in EV power management

Engineers testing vehicles pursue power management to improve efficiency, but that’s no simple task. For example, even if no problems are found during standalone testing of electrical accessories, discovery of unexpected power consumption or leakage current during testing after those components have been assembled into finished vehicles pose challenges due to the difficulty in identifying the location causing the problem. That’s because the identification process requires extended, simultaneous measurement of parameters across large numbers of channels, a task that is impossible with the clamp meters that are typically used in vehicle maintenance. Moreover, those pursuing effective power management in finished vehicles face the following sorts of requirements and issue:

· A desire to measure DC current on the order of dozens of milliamperes with a high degree of accuracy in order to ascertain current consumption and leakage current of ECUs and other devices

· An ECU is consuming current at unexpected times, but the component causing the issue cannot be identified

· A desire to check whether the fuses have the proper ratings at the fuse box of a finished vehicle

· A desire to investigate whether ECU leakage current falls within the normal range under a variety of conditions

A solution from Hioki for implementing EV power management

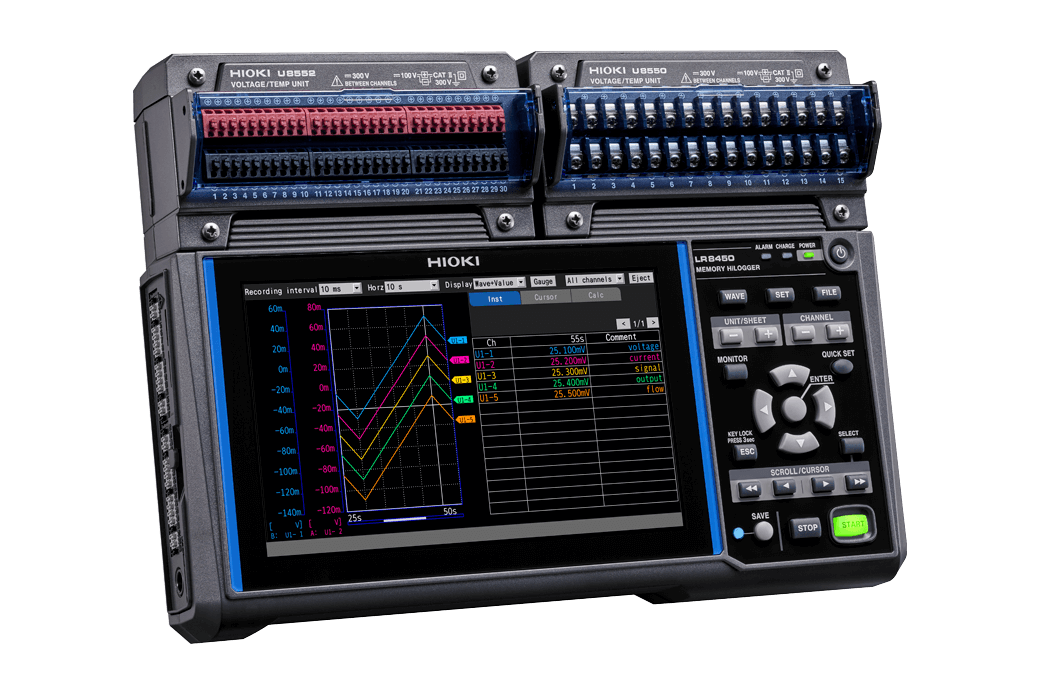

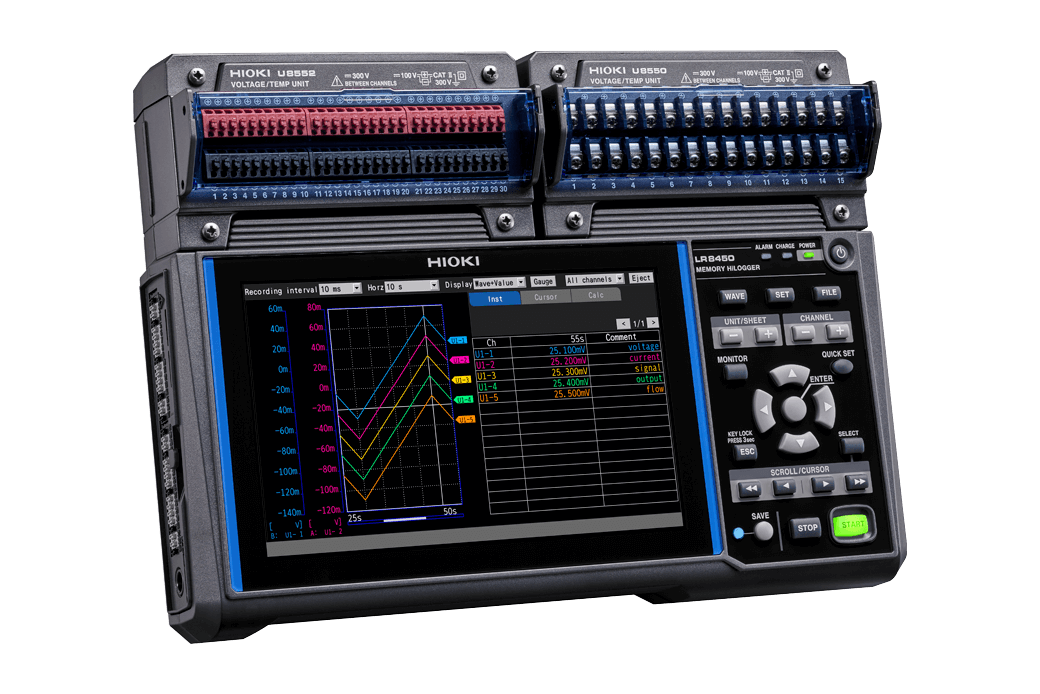

The Hioki LR8450, a data logger that can simultaneously measure current consumption and leakage current across multiple channels, is an ideal tool when you need to quickly identify an ECU or device whose current consumption is problematic. This multichannel logger can measure and record up to 330 channels of data. Depending on the combination of measurement modules used, the instrument can be used to simultaneously observe physical properties like current, voltage, temperature, and vibration as well as data being sent and received on a CAN bus. Used in combination with compact, high-accuracy DC current sensors, the LR8450 can simultaneously measure and record ECU and device current consumption over an extended period of time. Furthermore, the instrument can acquire data from a CAN bus at the same time, allowing for the integrated analysis of vehicle states and current consumption profiles.

The LR8450 and AC/DC Current Sensors CT7812/CT7822 are ideal for measurements made in EV power management for the following three reasons:

1. High-precision current sensors that are the size of an index finger

2. Support for CAN FD data acquisition

3. Ability to acquire data for an entire vehicle wirelessly (LR8450-01 only)

A solution from Hioki for implementing EV power management

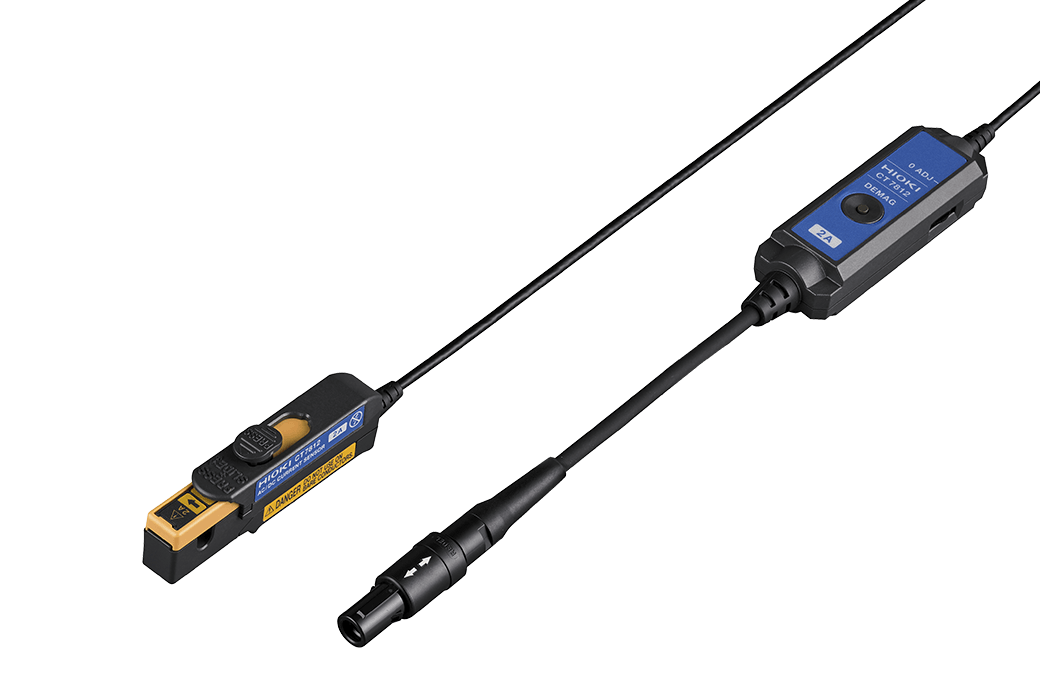

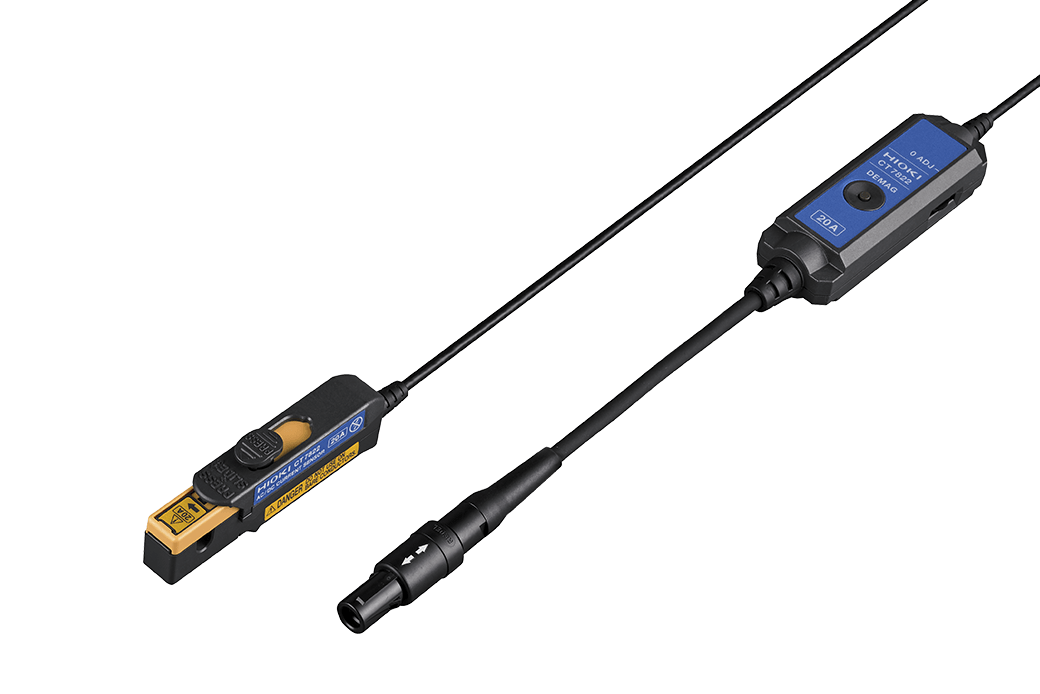

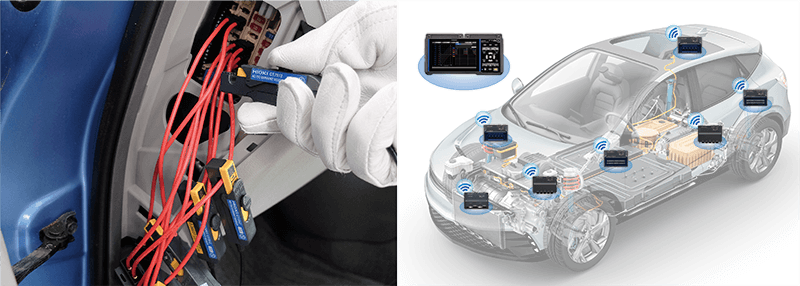

1. High-precision current sensors the size of a finger

The AC/DC Current Sensor CT7812 (2 A) and CT7822 (20 A) use flux gate technology. Thanks to exceptional temperature stability, they can record current consumption with a high degree of accuracy over extended periods of time. These compact sensors make it easy to access complex wiring inside vehicles, and they’re ideal for measuring current consumption for loads at multiple locations. To simultaneously and efficiently measure multiple loads, it’s recommended to connect sensors via a current loop from the fuse box. This approach eliminates time spent searching for the target load’s wiring.

2. Support for CAN FD data acquisition

The LR8450 also supports CAN FD, the standard communications system used in today’s multifunctional vehicles. The instrument can acquire on-board sensor data and ECU control data from CAN and CAN FD buses and display it in real time on a single time plot depicting fluctuations in current consumption. Since you can simultaneously check vehicle status when abnormal increases in current values occur, it's easy to figure out what’s going on.

3. Ability to acquire data for an entire vehicle wirelessly

To evaluate a vehicle, you need measurement data from multiple locations. That means making measurements in multiple, separate areas, for example in the fuse box at the front of the vehicle, luggage space temperature in the back, engine compartment heat, and body and driveshaft rigidity. However, attempting to acquire all of this data simultaneously may lead to complex wiring. Fortunately, the LR8450-01 supports wireless measurement modules. These modules can be powered independently by their own batteries. They can be positioned close to each measurement target and used to transfer measurement data to the data logger wirelessly. By reducing complex wiring in this way, you can boost work efficiency while reducing the risk of data loss due to wire breaks and noise.

Choosing the right sensor

Vehicles have DC current loads. Hioki offers DC current sensors that are suitable for various loads.

AC/DC Current Sensor CT7812:

For devices with a load current of 2 A or less such as ECUs, windshield wipers, power windows, window heaters, headlamps, etc.

AC/DC Current Sensor CT7822:

For devices with a load current of greater than 2 A (up to 20 A) such as power steering, air-conditioning compressors, water pumps, etc.

Hioki also offers current sensor options for measuring even larger currents

AC/DC Auto-Zero Current Sensor CT7731 (100 A AC/DC)

AC/DC Auto-Zero Current Sensor CT7736 (600 A AC/DC)

AC/DC Auto-Zero Current Sensor CT7742 (2000 A AC/DC)