Overcoming Efficiency Challenges in Chip Resistor Voltage Stress Testing Processes

Introduction

The rapid expansion of electric vehicles (EVs) and AI data centers has driven a surge in demand for high-reliability chip resistors (low post-stress resistance change), essential components for maintaining stable performance under rated voltage load. These resistors must undergo rigorous mass production inspections to ensure they meet stringent quality standards, including checks for resistance changes after applying rated voltage. Without proper verification, resistors may exhibit characteristics shifts during use, leading to early failures and compromising equipment reliability. This process traditionally involves multiple measurement steps, data recording, and calculations, which can complicate production lines and extend test cycle times.

The RM3542C Resistance Meter from Hioki addresses these verification challenges by offering a streamlined solution for inter-process comparisons, empowering production engineers to achieve higher reliability while reducing system complexity. With its ΔR function, the instrument simplifies inspections on taping machines, enabling quick anomaly detection and minimizing downtime. This approach not only enhances efficiency but also supports the overall productivity of high-volume manufacturing, ensuring components are market-ready with reduced risk of defects.

Background

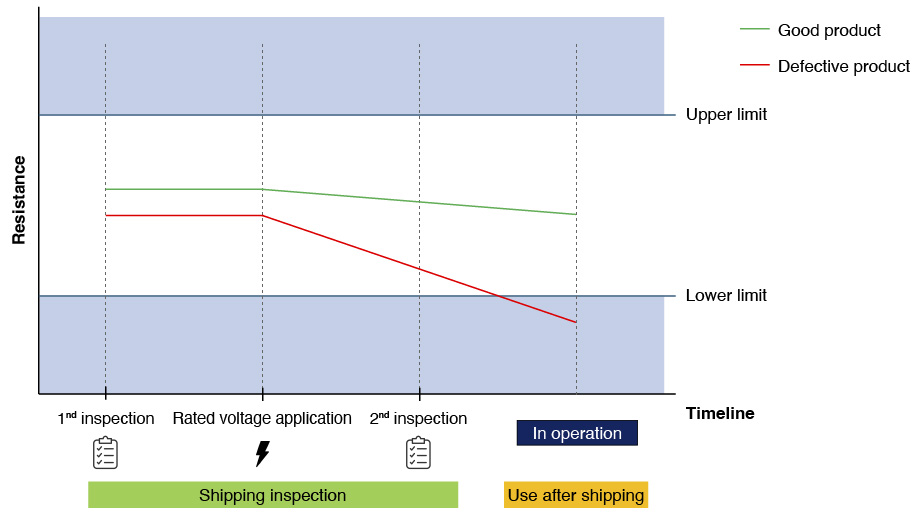

High-reliability chip resistors are critical in applications where stability is paramount, such as automotive electronics and data processing systems. During production, an initial resistance inspection is performed, followed by the application of rated voltage to induce stress. A second inspection then assesses any changes as voltage can exacerbate characteristics variations. Resistors showing significant shifts post-stress are prone to in-field degradation, potentially reaching specification limits prematurely (Fig. 1).

Fig. 1. Timeline of resistance inspection process for chip resistors, illustrating good and defective product trajectories.

In mass production lines, measurements confirm values fall within specified ranges, and resistance change rates (ΔR) after voltage application must stay within tolerances. These pre/post-voltage checks are now stricter ever, but ultra-short cycle times demand faster probing, inspection, and handling.

The Challenge

To verify resistance changes between processes, data from each measurement must be recorded, and the difference calculated to determine the change rate. Typically, this requires acquiring values from two separate meters, performing computations on a host system which then issues judgments. Such an approach complicates device control, as data reading and calculations add layers of software overhead. In high-speed mass production inspections, this inefficiency can slow down the entire line, increasing the risk of bottlenecks and reducing throughput for components that demand both precision and volume.

Production engineers face the dual pressure of maintaining high reliability—ensuring no defective parts escape to market—while optimizing for speed. Traditional methods burden the external controller (PLC/PC), leading to more complex programming and potential errors, ultimately hindering the taping machine's overall performance.

Solution and Benefits

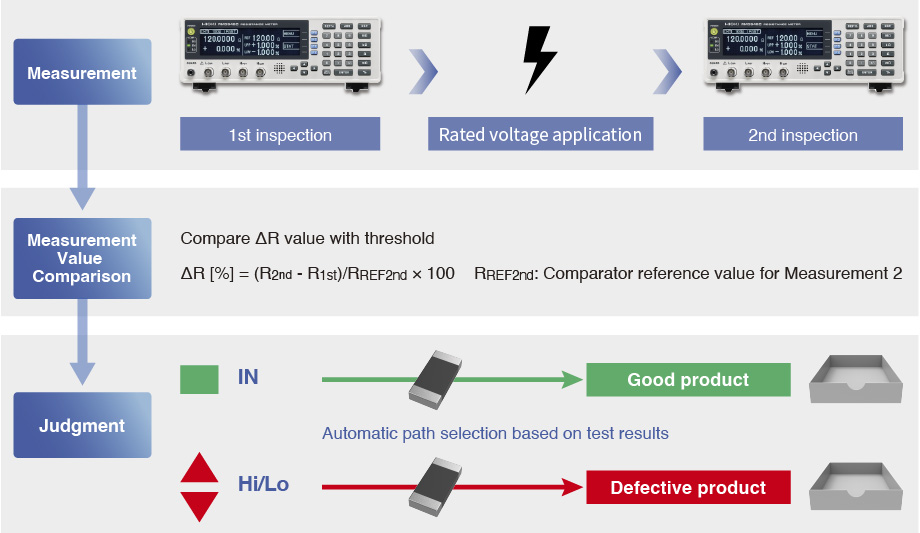

Hioki's RM3542C Resistance Meter, equipped with the ΔR function, provides an elegant resolution by connecting two RM3542C units—one for the first-stage measurement (RM3542C_1st) and one for the second-stage (RM3542C_2nd)—via a communication cable. The pre-voltage resistance value from the first stage is transmitted to the second unit, where the post-voltage measurement occurs (Fig. 2).

The change rate is then computed using the formula:

ΔR [%] = (R2nd - R1st) / RREF2nd × 100

(where R1st is the first-stage measurement, R2nd is the second-stage measurement, and RREF2nd is the comparator reference for the second stage)

Fig. 2. In-line inspection and automated taping control using the ΔR function and comparator-linked EXT I/O outputs to enhance pass/fail judgment and line efficiency

Based on the ΔR judgment and the standard comparator results from the RM3542C_2nd, signals are output via EXT I/O as detailed in Table 1. These outputs enable automatic sorting of good and bad products without relying on host system interventions, simplifying control and enhancing taping machine efficiency (Fig.2).

TABLE 1. COMPARATOR JUDGMENT TABLE WHEN ΔR FUNCTION IS EFFECTIVE

| Comparator judgment | |||||

|---|---|---|---|---|---|

| HI | IN | LO | (ERR) | ||

| ΔR judgment | HI | HI | HI | LO | ERR |

| IN | HI | IN | LO | ERR | |

| LO | HI | LO | LO | ERR | |

| – * | HI | ERR | LO | ERR | |

- *:Recovered from error

IN outputs only when both ΔR and comparator pass; HI or LO signals any failure. EXT I/O directly drives sorting—no host calculation needed. RM3542C cuts inspection time and simplifies line control.

Conclusion

In an era of escalating demands for high-reliability chip resistors, Hioki's RM3542C stands out as an optimal solution for mass production inspections, delivering a smart balance between quality assurance and operational efficiency. Its ΔR function eliminates the need for cumbersome host computations, enabling seamless integration into taping machines and safeguarding against early component failures. Production engineers benefit from enhanced precision, faster cycle times, and lower risks, ultimately supporting business continuity in competitive markets like EVs and AI infrastructure.

For a demonstration or consultation on a specific application, please contact us.