Surface and Volume Resistivity Measurement of Insulation Materials

Overview

To achieve carbon-neutrality, society is quickly switching to renewable energy sources such as solar and switching to battery-powered vehicles in various fields such as automotive, agriculture, construction, and aviation. The power consumption of electrical vehicle systems is increasing, with the components in these systems operating at high voltage, large currents, and even high temperatures. Furthermore, researchers are increasingly focusing on detailed tests of materials used in familiar components such as insulated cables, lubricants, and circuit boards, under test conditions that closely mimic actual usage conditions. Consequently, there is a growing demand for measuring the resistivity, an intrinsic property of materials of both batteries and other components.

In this article, we will explain the measurement of surface resistivity and volume resistivity for plastic materials, which are used in many applications.

Measurement of resistivity in flat-plate samples

Resistivity is typically measured using an instrument known as a super megohmmeter or electrometer in conjunction with a measurement electrode that is suited to the specific DUT (device under test). It is crucial to select the appropriate measurement electrodes based on the shape and projected resistance value of the DUT. For example, in the case of plastic materials with a flat-plate shape, during the research and development phase, engineers will fabricate small amounts or parts. This makes it much more practical to choose a measurement electrode that can accommodate small to medium sizes. Measurement electrodes also need to have high enough resistance measurement capability since the resistance of these material typically exceed teraohms.

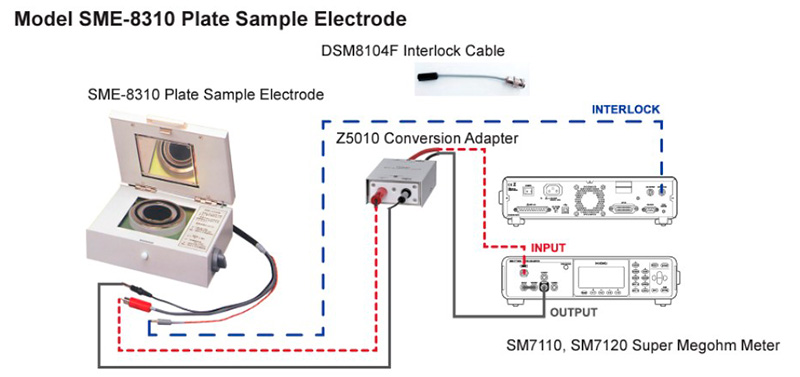

The SME-8310 and SME-8311 Plate Sample Electrodes are designed to measure square-shaped flat-plate DUTs with sides of 85–100 mm and 40–100 mm , respectively. By combining these electrodes with the SM7110 or SM7120*1 Super Megohmmeter, you can measure the surface resistivity and volume resistivity of plastic materials with 1 x 1016Ω or less (SME-8310) or 2 x 1016Ω or less (SME-8311). These megohmmeters allow you to select the model-name of the measurement electrode and input the thickness of the DUT. This allows the calculation result of resistivity to be displayed. If other unlisted measurement electrodes are used, you can input the electrode dimensions in addition to the thickness of the DUT. No additional calculation is needed since it calculates both the surface resistivity and volume resistivity with measurement*2. To increase test safety, the DSM8104F Interlock Cable is essential. It makes measurement safer by ensuring that voltage can’t be applied when the lid is open and electrodes exposed to touch.

By employing these tools and procedures, you can accurately measure the resistivity of flat-plate samples, providing essential data in evaluating their electrical insulating properties for various applications.

*1: The rated voltage of the SM7120 is 2000 V. However, the measurement setup in this application note is limited to 1000 V because the measurement electrode’s rated voltage is 1000 V.

*2: For detailed explanations on volume resistivity and surface resistivity, please refer to the "Insulation Resistance Measurement Handbook"

Examples measuring volume and surface resistivity of polyacetal (polyoxymethylene) resin

Using the SM7110 Super Megohmmeter, Z5010 Conversion Adapter, and SME-8310 Plate Sample Electrode, Hioki engineers measured the volume resistivity (ρV) and surface resistivity (ρS) of approx. 92 x 92 x 5.6 mm POM (polyoxymethylene) (see fig.1 and 2 below).

Fig. 1 test setup

Fig. 2 DUT

Taking into account the dielectric polarization*3, we obtained the values after 1 minute of measurement. The resistivity measurement parameters D1 (outer diameter of the main electrode) and D2 (inner diameter of the ring electrode) (see fig. 3) are automatically input when selecting the SME-8310 electrode. By entering the thickness (t) of the sample, ρS and ρV are automatically calculated. This experiment yielded results of ρS 2.99348 x 1014 Ω (see fig. 4) and ρV 7.37507 x 1013 Ωm (see fig. 5).

*3: Dielectric polarization is a phenomenon in which a dielectric material or insulator, is electrically polarized when an external electric field is applied to it. This results in resistance measurement drifting over time.

Setting items

- D1: Outer diameter of the main electrode

- D2: Inner diameter of the ring electrode

- T: Thickness of the DUT

- K: Electrode constant*

*Resistivity calculation for plate samples doesn’t include K, so no change is required.

Fig. 3 settings for the measurement electrode (ELEC)

Fig. 4 surface resistivity (ρS) measurement result

Fig. 5 volume resistivity (ρv) measurement result

Summary

The use of renewable energy and the electrification of equipment are advancing to achieve a carbon neutral society. As a result, components within electrical systems are exposed to high voltage, high current, and elevated temperatures. Therefore, it is essential to measure the resistivity—a key material property of these components. For measuring the resistivity of flat samples, it is necessary to use a super megohmmeter or electrometer and a specialized measurement electrode. For measuring both volume and surface resistivity of plastic materials, it’s easy to use the SME-8310 or SME-8311 Plate Sample Electrode with the SM7110 or SM7120 Super Megohmmeter.

For more information on resistivity measurement and detailed product information, please refer to the links below.