ALDAS-Mini : ELECTROLYSIS CELL ANALYZER

Visualizing Dynamic Characteristics of Electrolysis Cells

& Optimizing Operational Efficiency

The ALDAS-Mini (Electrolysis Cell Analyzer) is a compact, high-performance solution designed to accelerate R&D in electrolysis cell technology. Engineered for precision, it enables advanced analysis of electrolysis cells, playing a pivotal role in the global transition to sustainable, hydrogen-based energy systems.

Electrolysis cells are essential for generating clean hydrogen, a critical component in achieving carbon neutrality. The ALDAS-Mini empowers researchers and engineers to optimize operational parameters, reduce costs, and improve efficiency by delivering insights into cell performance under operating conditions. This system supports the pursuit of cleaner energy solutions and a sustainable future.

Product Video

This video will introduce the methods for connecting this system to the measurement target, the configuration procedures, and some measurement examples.

Key Features

- Innovative impedance measurement: max. 500 A electrolysis current

- Ease of integration: requiring no modifications to existing systems

- Simultaneous multi-cell measurement: up to 8 cells in a stack

- High-precision measurements in noisy environments: consistent and reliable results

- Wide compatibility: supports electrolysis cell types including PEM, SOEC, AEM, AWE, etc.

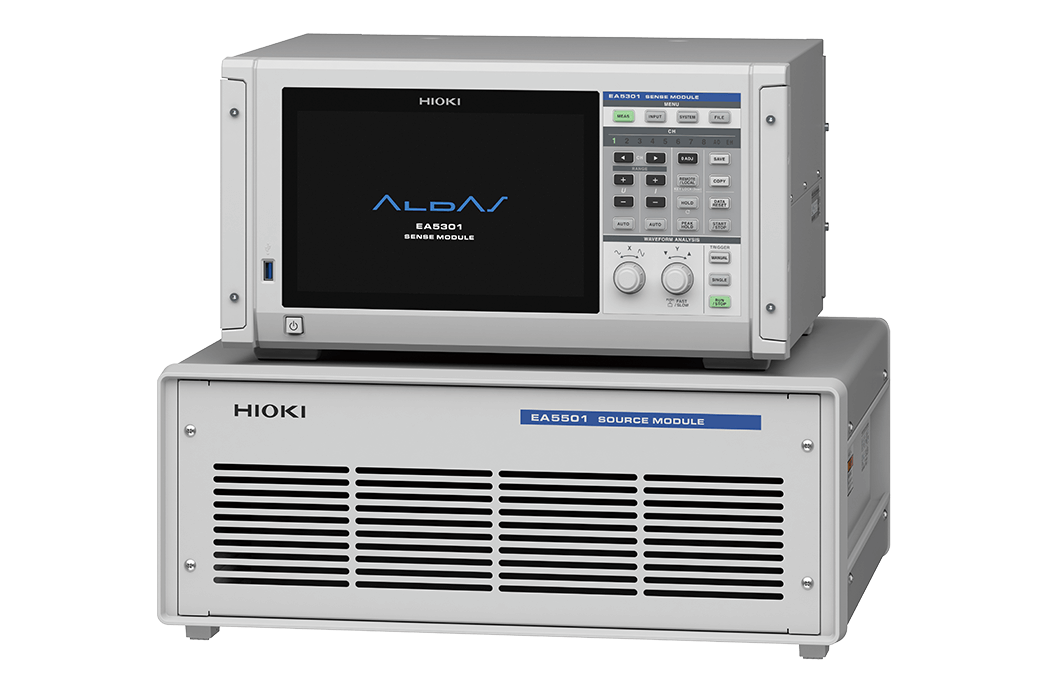

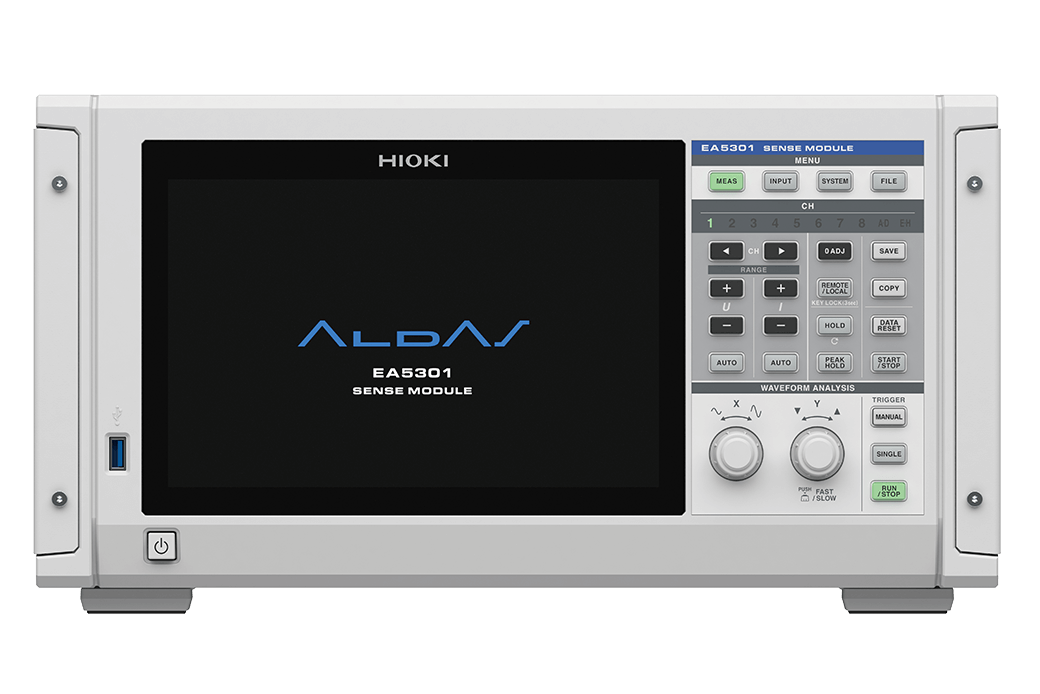

Model No. (Order Code)

| EA5301-01 | SENSE module 1ch |

|---|---|

| EA5301-02 | SENSE module 2ch |

| EA5301-03 | SENSE module 3ch |

| EA5301-04 | SENSE module 4ch |

| EA5301-05 | SENSE module 5ch |

| EA5301-06 | SENSE module 6ch |

| EA5301-07 | SENSE module 7ch |

| EA5301-08 | SENSE module 8ch |

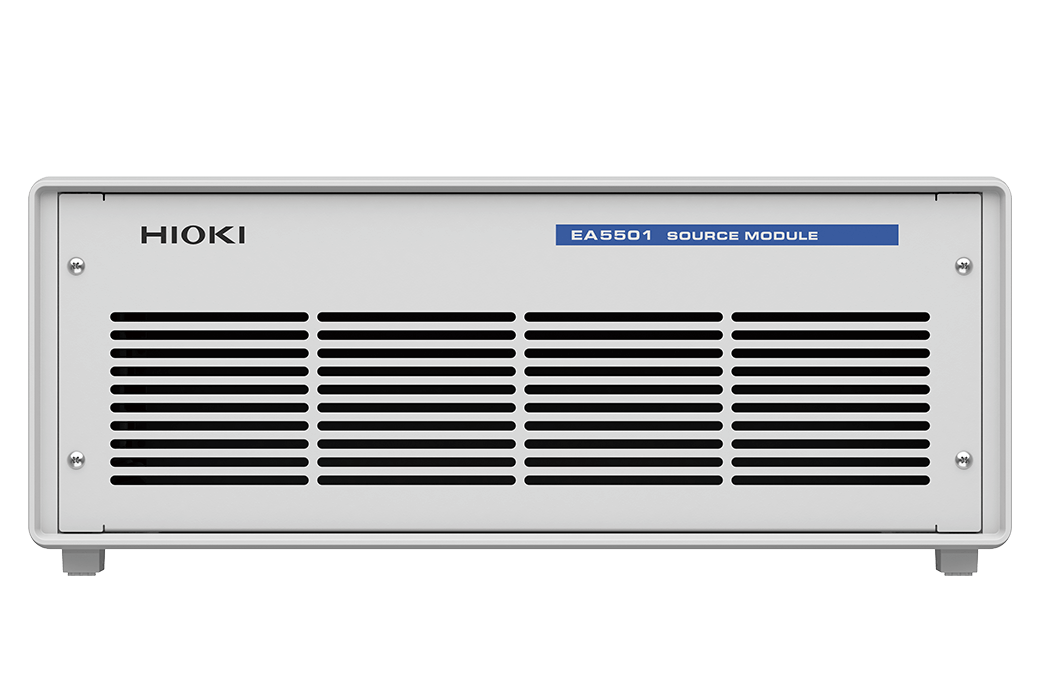

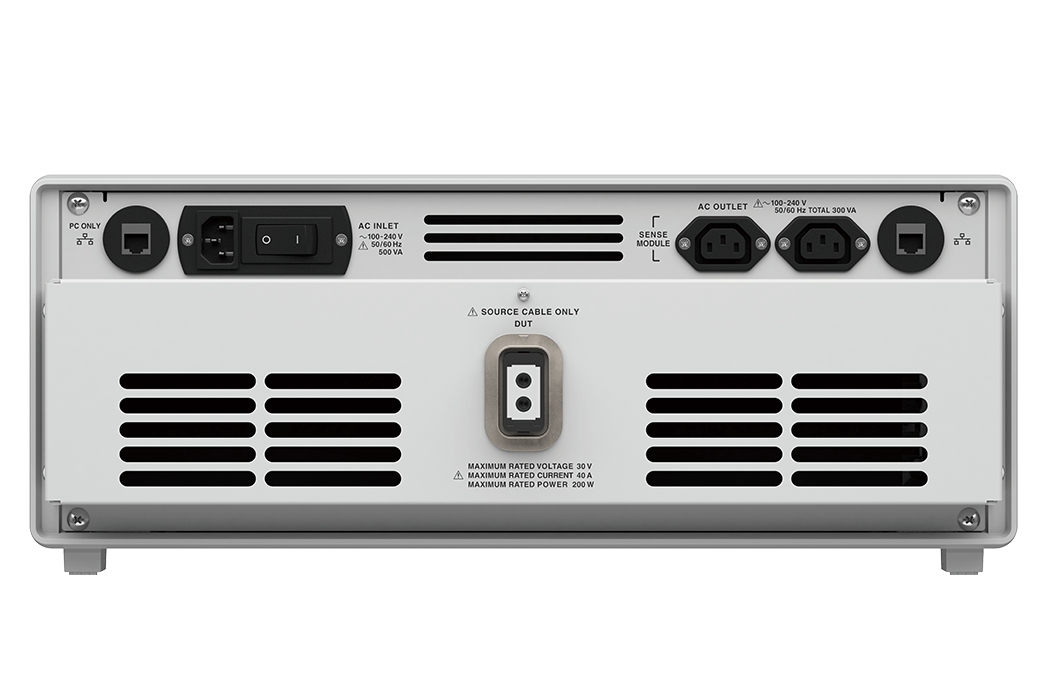

| EA5501 | SOURCE module |

| EA5701 | PC application software |

Accelerate electrolysis cell development via high-current operational testing

Revolutionizing EIS measurement: Solutions for electrolysis cells and stacks with the ALDAS-Mini

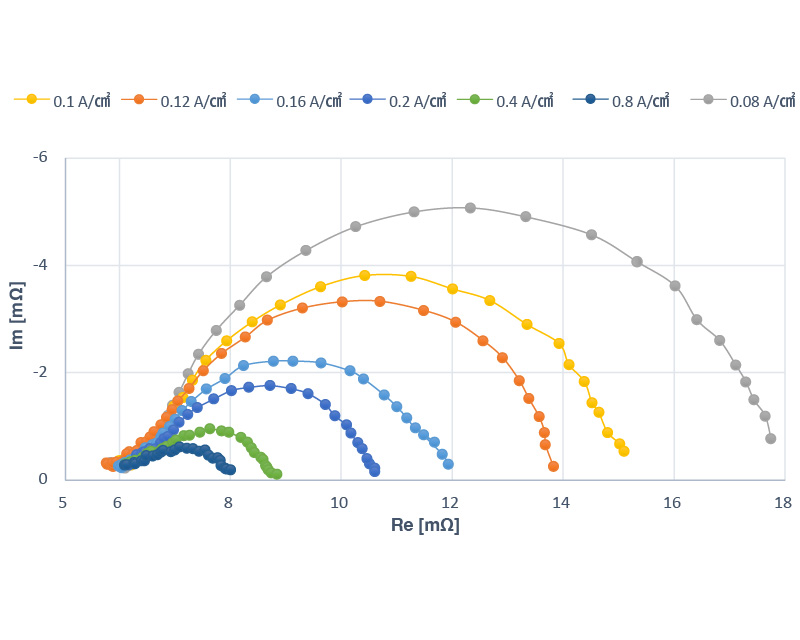

EIS (Electrochemical Impedance Spectroscopy) measurement of electrolysis cells used to face challenges in measuring large cells or cell stacks with high currents. The ALDAS-Mini addresses this issue by enabling EIS measurement for a wide range of cell sizes, from small cells with electrolysis currents of a few amperes to large cells with currents of up to 500 A (*1).

Additionally, the system can measure up to 8 cells simultaneously within a cell stack, allowing for comparative analysis of the state of each cell during electrolysis.

Main Applications

• Evaluation of large cells exceeding 100 cm²

• Optimization of hydrogen production

• Monitoring cell health and diagnosing degradation factors

• Material research

- *1:If your electrolysis current measurement requirements exceed 500 A, please contact your Hioki representative.

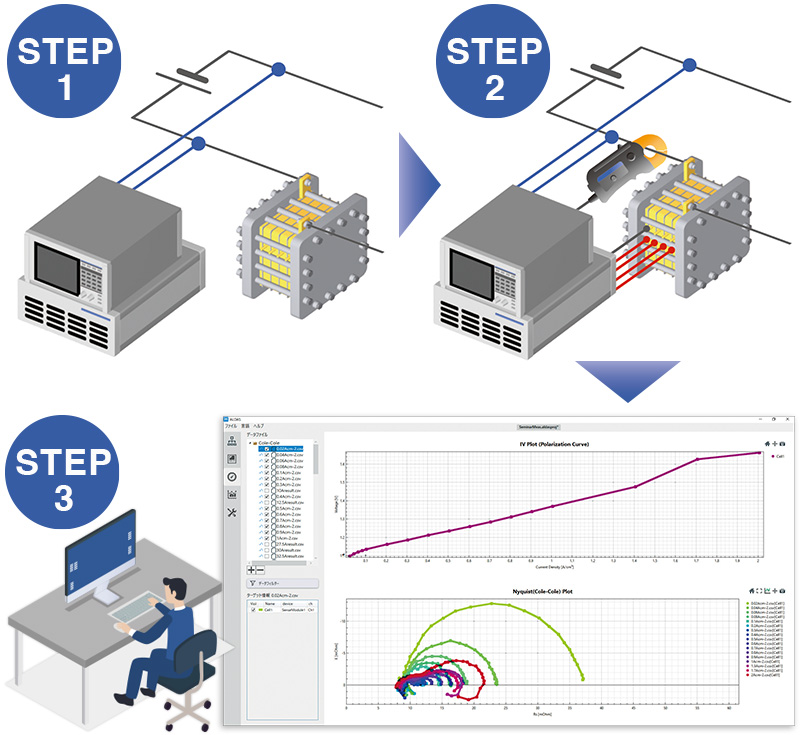

Just simply connect to your existing system

Designed for seamless setup, requiring no modifications to existing systems

No modification to your electrolysis system is needed to set up the ALDAS-Mini.

Unlike conventional booster-equipped FRA (Frequency Response Analyzer) devices, the ALDAS-Mini operates seamlessly alongside the cells' DC power supplies.

STEP 1: Applied current connection

Connect the SOURCE module to the cell’s power source terminal with the SOURCE Cable.

The SOURCE module applies AC current for measurement.

STEP 2: Measurement line connection

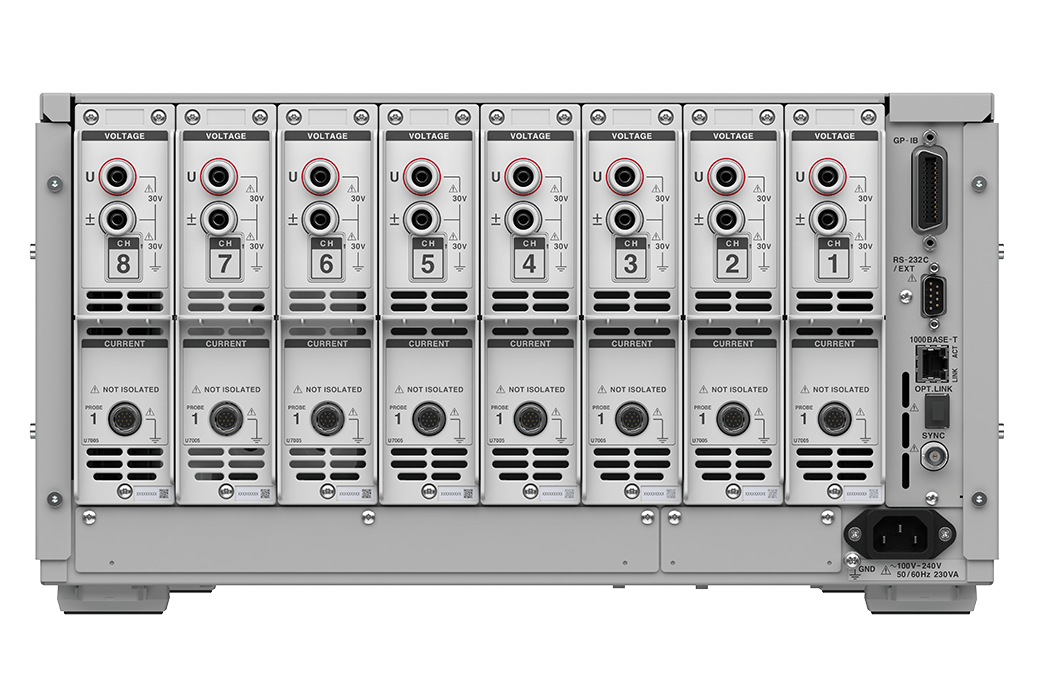

Attach the current sensor to measure the current. Then, connect the SENSE cable to the cell to measure the voltage (both connected to the SENSE module).

STEP 3: Start measurement

Start the measurement after configuring the necessary settings in the dedicated PC software.

The I-V curve and Nyquist plot are displayed simultaneously in real-time, with impedance calculated from the measured current and voltage.

Basic specification

| Measurement target | Electrolysis cell, cell stack |

|---|---|

| Measurement parameters | Impedance (R,X,θ,Z), voltage (V), current (I) |

| Measurement modes | Logging mode, Nyquist plot mode, Bode plot mode |

| Max. input voltage | 30 V |

| Max. measurable current | 4 mA to 500 A (the necessary current sensor will change according to the rated current) If your measurement requirements exceed 500 A, please contact your Hioki representative. |

| Max. measured signal level | 20 Ap-p (at 10 V) |

| Measurement frequency | 0.01 Hz to 10 kHz |

| Number of input channels | Up to 8 channels |

| Dimensions and weight | SENSE Module EA5301 (with 8 channels): approx. 430W × 221H × 361D mm (16.9W × 8.7H × 14.2D in.) (excluding protruding parts), approx. 12.7 kg (28.0 lbs) SOURCE module EA5501: approx. 520W × 197H × 540D mm (20.5W × 7.8H × 21.3D in.) (excluding protruding parts), approx. 27.0 kg (59.5 lbs) (not including cables) |

| Power supply | 100 V to 240 V AC, 50 Hz/60 Hz, 500 VA |

| PC requirements | OS: Windows 11 Interface: wired LAN |

Current sensors (8)

Connection cables (2)

Small alligator clips, 2.2 m (7.2 ft.)

Large alligator clips, 2 m (6.6 ft.)