Power Quality: Definition, Why and How Do We Measure It?

What is power quality?

Definition

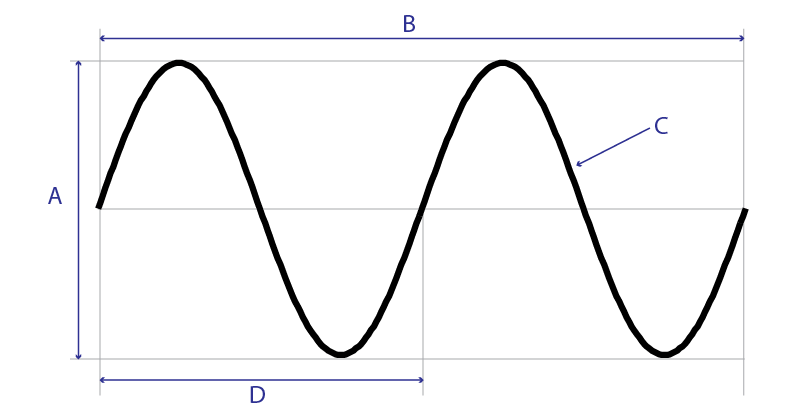

Power quality is a general term to represent the phenomena affecting to the user’s equipment when the AC power exceeds a certain limit. Fig. 1 shows the electricity waveform that serves as an indication of the quality of a power supply. It must be stable in terms of its amplitude, continuity, waveform shape, and frequency.

- A : Amplitude

- Stability in the voltage RMS value

- B : Continuity

- No interruption to the waveform

- C : Waveform

- Clean in shape, not distorted

- D : Frequency

- Stability in terms of providing the same range of frequency values

Fig. 1 Example of voltage waveform

Fig. 1 Example of voltage waveform

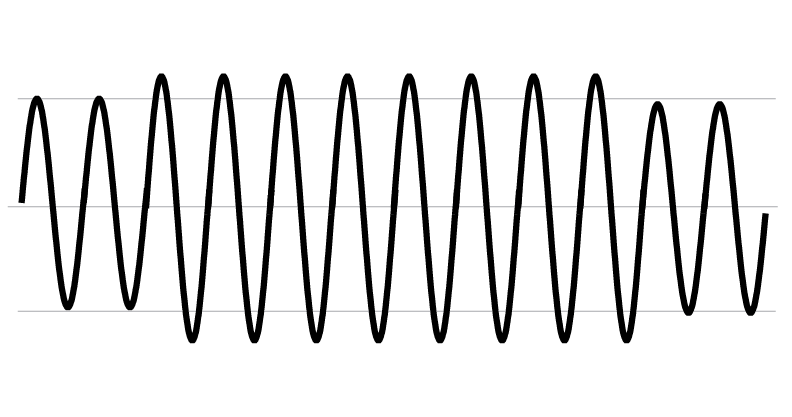

Suppose for some reason, the waveform shown in Fig. 1 exceeds a certain limit, resulting in poor power quality. Then the waveform may look like Fig. 2, representing a phenomenon called voltage swell (surge), in which voltage rises momentarily. A surge in voltage may cause the power supply of the device to be damaged or the device to reset.

Fig. 2 : An example of a voltage swell (surge) waveform

Fig. 2 : An example of a voltage swell (surge) waveform

Why do we measure power quality?

Natural phenomena such as lightning strikes, poor load distribution, and wiring and grounding issues are a few examples of the causes of power quality problems. Inverter-based technology has become more common in recent years, as have grid-connected electric vehicle chargers and grid-tied renewable energy sources such as solar and wind power. These make the power network more complex and have a significant negative impact on power quality.

Poor power quality causes trouble in receptacle/transmission equipment and electronic equipment malfunctions. For example, harmonics are known to cause burn-out in reactors and generate defective noise in capacitors. Also, impulse or transient noise and voltage drops stop control systems that are dependent on a computers.

Power supply network problems caused by poor power quality is a common problem for both electric power suppliers and users. However, it is not easy to identify whether the cause of poor power supply quality is at the supplier’s system or the user’s system. Because of this situation, power quality measurement is necessary to understand the actual cause of power quality problems as well as to consider and analyze for effective countermeasures.

How do we measure power quality

Power quality is often measured based on standards. The standards serve as guidelines for measuring and evaluating the quality of the electrical power supply. They ensure that measurements are consistent, assist in identifying what types of power quality issues exist, and ensure that power systems meet specific quality and reliability standards. They provide guidelines for evaluating and enhancing the quality of electrical power. Here are some examples of the international standards for power quality.

- IEC 61000-4-30

- An international standard stipulating how power quality should be measured. It classifies the measurement methods and capabilities of measuring instruments into two classes of A and S. The more reliable power quality measurement is Class A. The requirements for Class A are not only stipulated in terms of functions and accuracy, but also include detailed measurement algorithms and time clock accuracy.

- IEC 61000-4-7

- An international standard governing measurement of harmonic current and harmonic voltage in power supply systems as well as harmonic current emitted by the equipment. The standard specifies the performance of a standard measuring instrument.

- IEC 61000-4-15

- A standard that defines testing techniques for voltage fluctuation and flicker measurement as well as associated measuring instrument requirements.

- EN 50160

- A European standard of power quality that defines limit values for supply voltage and other characteristics.

- IEEE 1159

- Recommended practice for monitoring power quality.

- IEEE 519

- Standard related to voltage harmonics and current harmonics.

A power quality analyzer is an instrument that is used when performing power quality measurements. This instrument is used for measuring and analyzing various aspects of an electrical power supply for extended periods of time. It records data on voltage, current, frequency, harmonics, transients, and other parameters in order to analyze power quality. This allows professionals to diagnose issues with power quality, ensure compliance with standards, and optimize the performance of electrical systems.

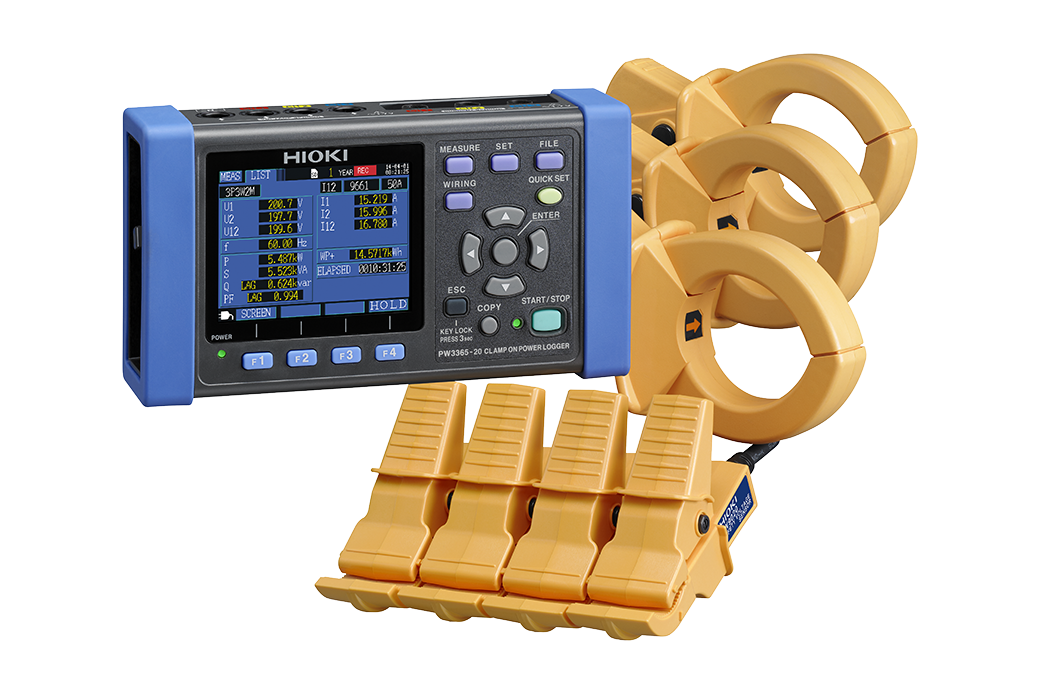

Solutions from Hioki

At HIOKI, we provide a few types of power quality analyzers and power loggers that can be used for commercial line power measurement.

| Product model | PQ3198 | PQ3100 | PW3360-21 | PW3365 |

|---|---|---|---|---|

| Power and Harmonics recording | Yes | Yes | Yes *1 | Yes *2 |

| Power quality measurement | Yes | Yes | No | No |

| IEC 61000-4-30 | Class A | Class S | — | — |

| EN 50160 measurement | Compliant | Compliant | — | — |

| IEEE 519 | Compliant | Compliant | — | — |

| Best for | When you need to examine, diagnose, and countermeasure the power supply condition that causes issues in equipment | When you need to conduct a power survey to understand the load size in a system or to understand the power quality in a system | When you need to understand the power consumption of a facility or system | When you need to understand the power consumption of a facility or system |

- *1:Up to 40th order

- *2:Up to 13th order

As the world progresses toward decarbonization and sustainability, the number of diverse grid-connected innovative solutions will expand, as will the complexity of power sources---not to mention the growth of inverter-powered energy-saving technology. As these trends become more prevalent, it is critical to examine how these factors affect power quality on both the consumer and supply sides. The HIOKI power quality analyzer will assist you in better understanding your power quality.