Optimizing Conductive Additive Levels in Dry Process Electrode Materials for Better Efficiency

Enhancing Dry Process Electrode Development with Advanced Material Evaluation

Lithium-ion batteries, widely used in various applications, traditionally rely on wet processes for electrode manufacturing. This involves dispersing active materials in solvents like water or N-methyl-2-pyrrolidone (NMP) and coating them onto current collectors. However, the drying step to evaporate these solvents consumes significant energy—accounting for about 40% of the total manufacturing energy—and results in substantial CO2 emissions. As global demands for sustainability intensify, particularly in the battery sector for electric vehicles (EVs) and energy storage, alternatives are essential to minimize environmental impact and production costs.

An attractive alternative is the dry process, a solvent-free method already proven in electric double-layer capacitors. By eliminating solvents, it reduces energy use, lowers CO2 output, and cuts overall cell costs. Yet, developing optimal dry process materials poses challenges, such as determining the right conductive additive content and mixing times to achieve efficient electron pathways without compromising material integrity. The Hioki Powder Impedance Measurement System addresses these dry-process material evaluation challenges by enabling precise evaluation of powder materials, empowering R&D engineers to streamline processes and accelerate innovation.

This application note explores its use in assessing conductive additive ratios and mixing durations for positive electrode mixtures, highlighting how it promotes efficient electrode development.

Background and Challenges in Dry Process Material Evaluation

The push for sustainable battery solutions has spotlighted dry processes, especially for Battery Electric Vehicles (BEVs). These methods promise reduced environmental footprints but require meticulous material assessment. Key problems include high evaluation costs, and extended processing times. Traditional systems often demand multiple instruments, heightening error potential and inefficiencies.

In dry electrode preparation, varying conductive additive (e.g., acetylene black, AB) content and mixing times can lead to inconsistent percolation networks, where conductive particles fail to form continuous paths, resulting in high resistivity and poor battery performance.

Solution: Leveraging the Hioki Powder Impedance Measurement System

The Hioki Powder Impedance Measurement System offers an integrated solution for these issues, combining a compact press unit, measurement modules, and dedicated software. For R&D personnel, it enables quick, accurate assessments of material properties, reducing downtime and costs while enhancing precision.

Measurement target

In this application example, the system evaluated dry process positive electrode materials composed of nickel-cobalt-manganese (NCM) active material, AB conductive additive, and polytetrafluoroethylene (PTFE) binder. Samples were prepared with NCM:AB:PTFE ratios of 100:x:3, where x ranged from 1.5 to 5.5 in 0.5 increments. Total mass was 10 g per sample, mixed using an automatic mortar for 10, 30,and 60 minutes to fibrillate the PTFE.

Measurement Conditions

Measurement conditions included DC resistance measurement with the RM3545A resistance meter, 100 mg sample weight, loads from 0.10 to 10.00 kN, and a 10 mm electrode diameter. This setup allowed for volume resistivity calculations, focusing on percolation thresholds and mixing effects.

Measurement Results and Insights

Changes in Volume Resistivity Due to Differences in Conductive Additive Content

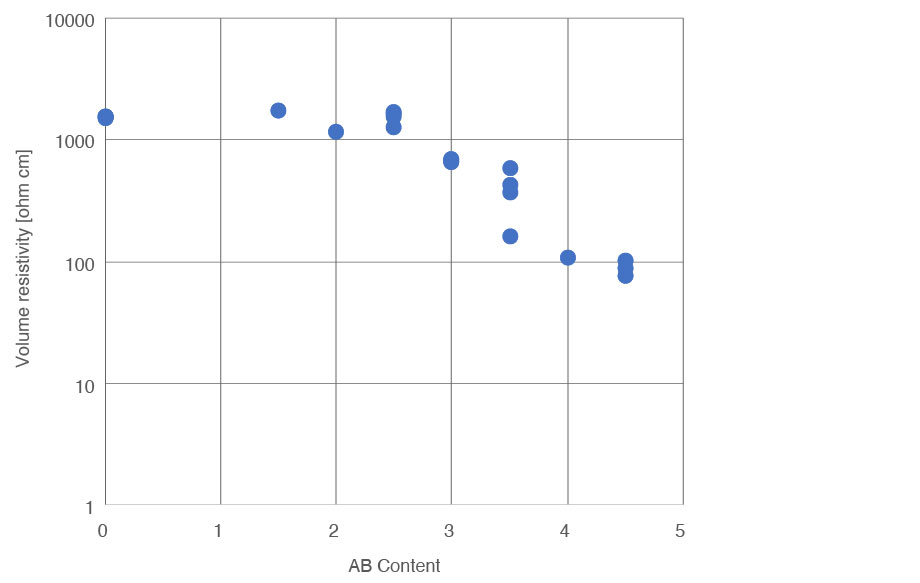

Volume resistivity was varied with AB content at 10-minute mixing time and 1 kN load. (Fig. 1)

Fig. 1. Volume resistivity variation with respect to the ratio of conductive additives.

At AB ratios of 1.5 to 2.5 (as above, 100:x:3, with x being AB), resistivity mirrored pure NCM. A sharp drop occurred between 3.0 and 3.5, with diminishing reductions between 4.0 and 4.5. The percolation threshold—where conductive networks form for efficient electron flow—appeared around 3.5. Thus, for optimal dry process electrodes, AB should exceed this threshold to ensure low resistivity and high conductivity, benefiting R&D by enabling faster material optimization. Upon observation of this optimal AB ratio, further experiments were performed at this ratio with varying mixing times of 10, 30, and 60 minutes.

Relationship between mixing time and volume resistivity

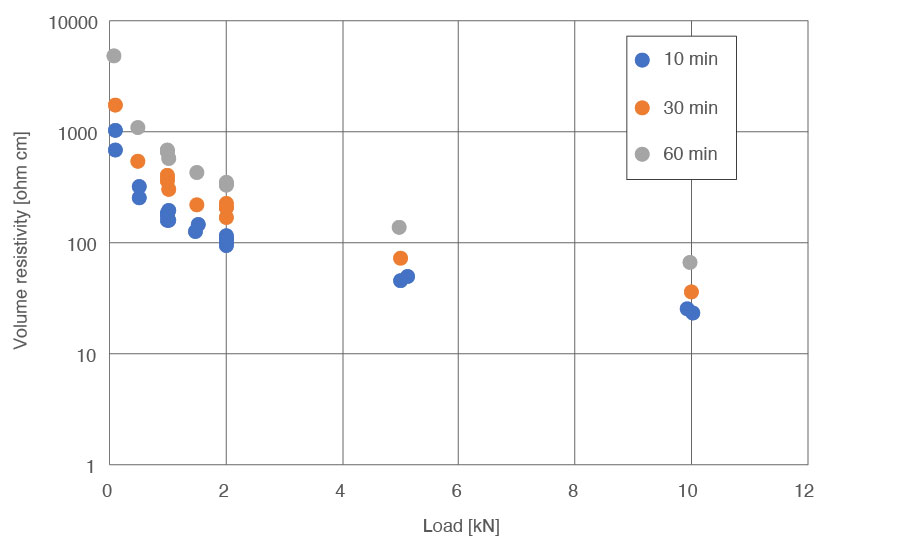

For samples with an AB ratio of 3.5, the graph shows the change in volume resistivity per load. (Fig. 2)

Fig. 2. Change in volume resistivity as a function of load for different mixing times.

For this ratio, longer mixing time increased resistivity across loads. This suggests potential network disruption or PTFE coating on AB particles.

Measured sample

Visual inspection showed 10-minute mixes as powdery and prone to scattering, 30-minute as cohesive, and 60-minute as re-powdered with high fluidity. The 30-minute mix emerged as ideal, balancing integrity and performance.

Fig. 3. Picture of samples with mixing times of 10, 30, and 60 min.

Conclusion: Advancing Battery Innovation

The Hioki Powder Impedance Measurement System transforms dry process material evaluation, making it accessible and efficient for R&D engineers tackling battery challenges. By identifying the optimal conductive additive levels and mixing times, the dry process can be advanced as a practical manufacturing method—leading to cost reductions, minimized CO2 emissions, and continuous progress in sustainable energy development.

For those in battery R&D, this tool not only addresses current hurdles but also paves the way for next-generation innovations.

For detailed product information, please visit our website.

For a demonstration or consultation on a specific application, please contact us.