Protective continuity testing

Why is protective continuity testing important and what are the test conditions?

The goal of protective continuity testing is to check whether a device’s ground connection is characterized by a reliably low resistance value. Principal test conditions are as follows:

• Test current: 25 A or 1.5× the rated current, whichever is greater

• No-load voltage: 6 V or less

• Test time: As per standard (5 to 10 s, 60 s, etc.)

• Allowable value: 0.1 Ω (device with power socket) or 0.2 Ω (device with fixed power cord)

How do I test for protective continuity?

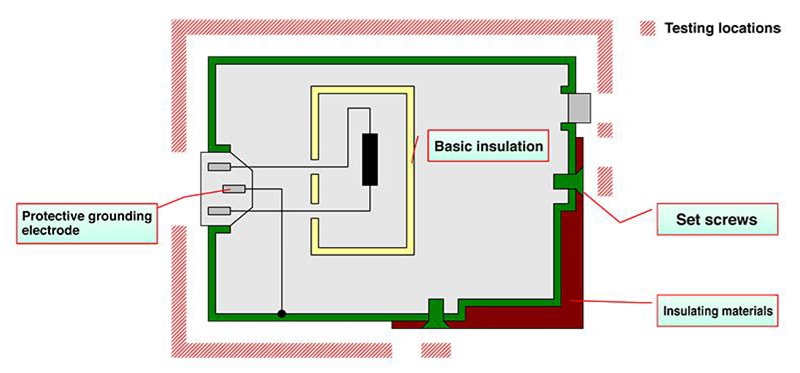

Protective continuity testing is performed at the protective grounding electrode and locations that are grounded (enclosure panels, screws, etc.).