What is Resistivity?

Overview

Electric resistance is commonly measured to evaluate quality of components such as motor winding and busbar welds. Unlike resistance, which is a simple measurement of how much electricity is impeded or resisted by a physical object, resistivity is an intrinsic property of materials. It plays a crucial role in the selection of materials for product design and material development.

This article provides an overview of resistivity and discusses the methods used to measure it.

What is resistivity?

Resistivity is an electrical property or characteristic of a material which indicates how strongly the material resists electric current.

Materials can be categorized into three types based on their resistivity: conductive materials, semiconductors, and insulating materials. Product developers consider these characteristics to choose materials that match their mechanical, chemical, and electrical needs. For instance, semiconductor devices like MOSFETs (metal–oxide–semiconductor field-effect transistors) use a semiconductor wafer as the active region where electrical behavior is controlled. Metal wires are used for conductive connections, and insulating materials provide protection.

Identifying the optimal combination of these materials is crucial, with resistivity being a key factor in this selection process.

Why does resistivity matter?

Unlike resistance, which depends on the size and shape of an object, resistivity is an unchanging characteristic of a material. For a practical example, let’s say you want to place a large order of cables and want to buy one that is best at conducting electricity. You want to choose from two cable types that you have in stock, but they are not the same length. If you use resistance to compare the two, you have to cut the two cables to be the same length and then measure. But if you measure resistivity, you can simply make your measurement and choose the cable with the smaller value. In this way, resistance measurements only indicate how easily electric current travels through the specific cable (length and all). Resistivity, however, allows us to compare how much each material inherently resists electricity.

Types of resistivity

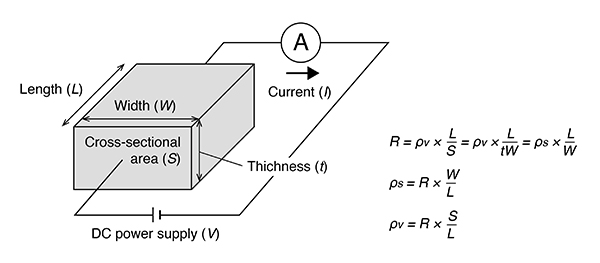

There are two commonly used types of resistivity: volume resistivity and surface resistivity. Volume resistivity, denoted as ρV [Ω⋅m], can be derived from an object’s resistance (R), cross-sectional area (S), and length (L). This property remains constant regardless of the material's size or volume (see equation below). On the other hand, surface resistivity, denoted as ρS [Ω/□ or Ω/sq.], also known as sheet resistance, refers to just the resistance of one surface area. Although it is not as practical a value because it does not account for how resistance rises with thickness, it is particularly useful for characterizing thin materials.

How is resistivity measured?

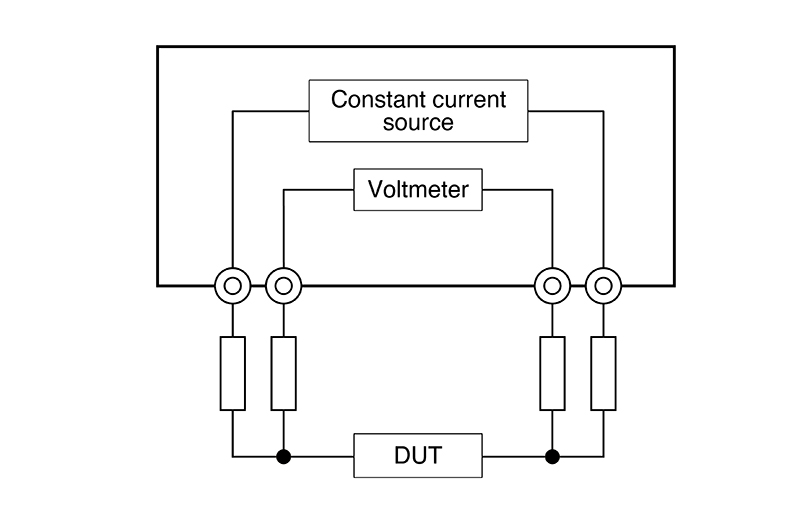

The method for measuring resistivity varies depending on the type of material. For materials of low to medium resistivity (approx. between a few µΩ⋅m and 100 MΩ⋅m), such as metal foils and semiconductor wafers, the measurement method called the four- terminal measurement method (constant current) is used because it can eliminate errors related to contact and cable resistance. When this method is implemented using a four-point probe with a fixed probe spacing, it is often referred to as the four-point probe measurement method.

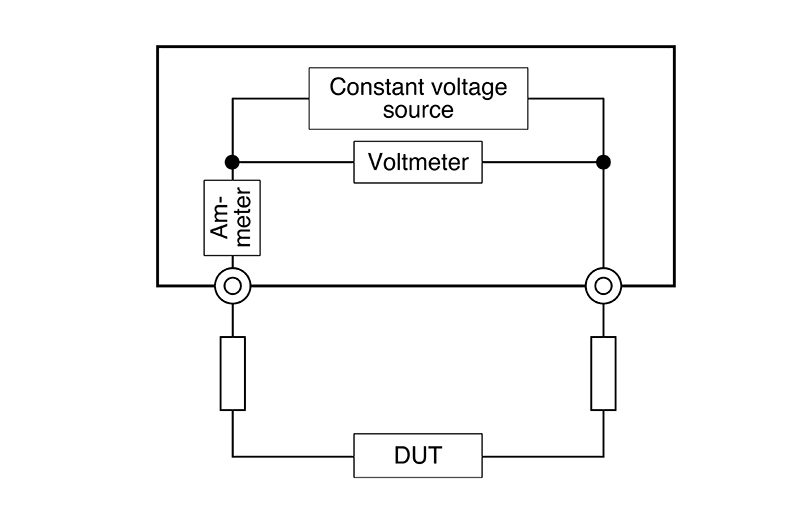

For high-resistivity materials (approx. 100 MΩ⋅m or greater) such as insulating materials, the measurement method typically used is the two-terminal measurement method (constant voltage) to get rid of errors caused by leakage current to the voltmeter.

Two-terminal measurement method

Two-terminal measurement method Four-terminal measurement method

Four-terminal measurement methodSince resistivity can be influenced by the measurement methods and conditions, we must ensure consistency throughout samples. Fortunately, industrial standards such as IEC 61340-2-3 and ASTM D-257 are available to guide these measurements and ensure comparability.

When measuring very low or very high resistances, handheld digital multimeters may not be good enough. For these applications, Hioki recommends specialized measurement instruments: resistance meters for low-resistivity materials, and super megohmmeters or electrometers for high-resistivity materials.

Low resistivity: resistance meters

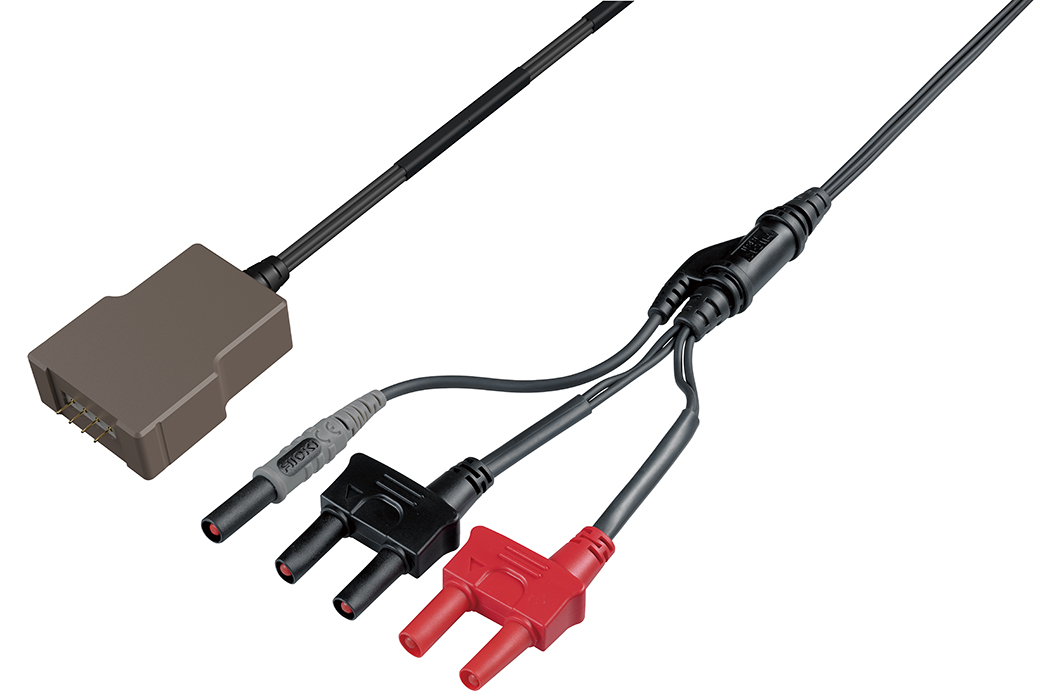

Equipped with a four-point test probe, resistance meters measure resistance by first applying a set current to the device under test (DUT), sensing the voltage drop, and calculating the resistance with Ohm’s law. After resistance measurement, Hioki’s PC application calculates resistivity by multiplying the resistance measurements by entered DUT’s thickness and a correction factor based on the thickness. Resistivity measurement setup for low-resistivity materials

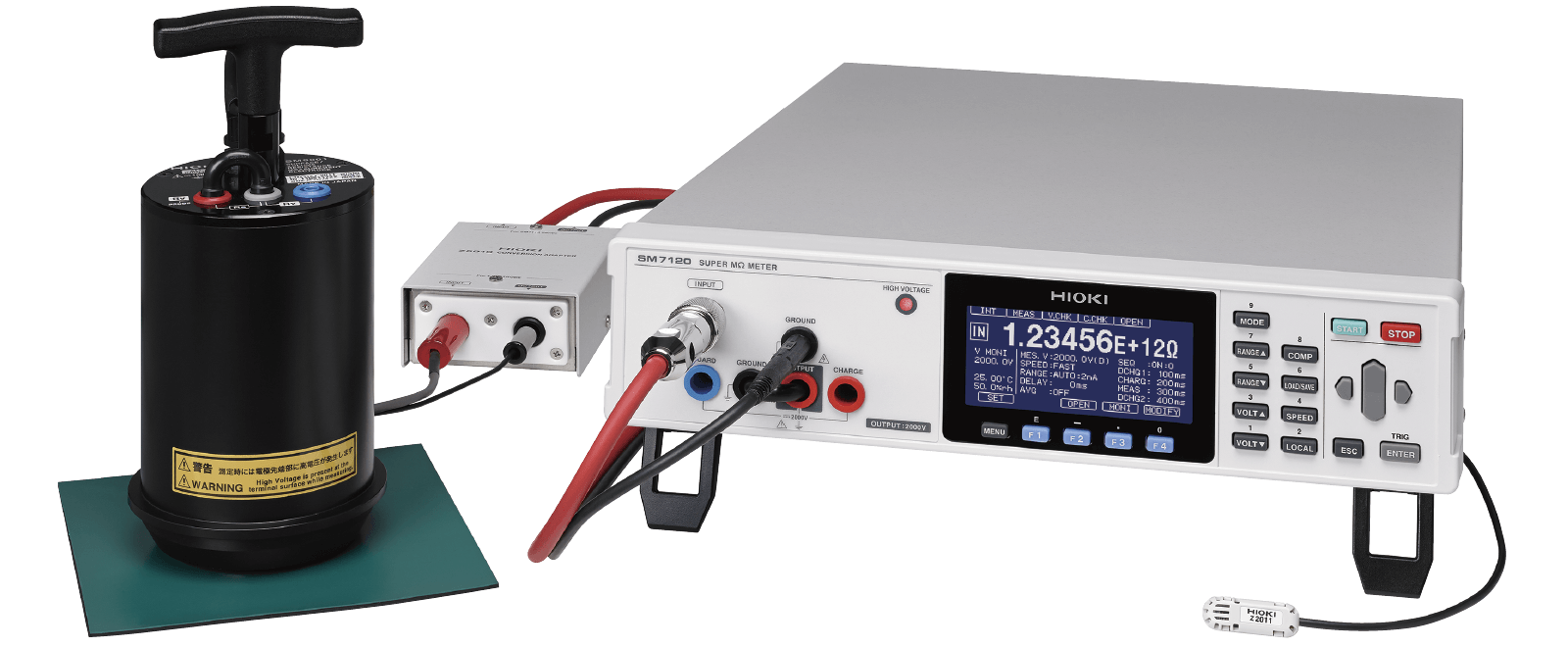

Resistivity measurement setup for low-resistivity materialsHigh resistivity: super megohmmeters

Although it can be said that the two-terminal measurement method is typically used to measure high-resistivity materials, practically speaking, test technicians need not worry about theoretic methodology since specific test electrodes are often specified in industry standards. Technicians will use these in conjunction with a super megohmmeter to find the resistivity. One thing to account for when measuring high-resistivity materials is that measurement values will drift over time due to a natural phenomenon. To counteract this and enable comparability, tests standards typically recommend the recording of resistance/resistivity measurements after one minute of continuous measurement (one continuous minute of test-voltage application). Resistivity measurement setup for high-resistivity materials

Resistivity measurement setup for high-resistivity materialsSummary

Resistivity is an intrinsic property that indicates how strongly a material resists electric current, unlike resistance which varies with size and shape. It is a crucial factor when selecting materials for various applications, such as electronics and insulation. Technicians must use measurement methods that match the material’s properties, such as the four-terminal measurement method (four-point probe measurement method) for lowly resistive materials and the two-terminal measurement method for highly resistive materials. Standardized conditions and specialized tools ensure accurate and comparable resistivity measurements.

To understand more about resistivity and resistance measurement, check out our reading recommendations below.

Related Products

Learn More