Verify the Power Quality and Efficiency of an EV fast charger

Introduction

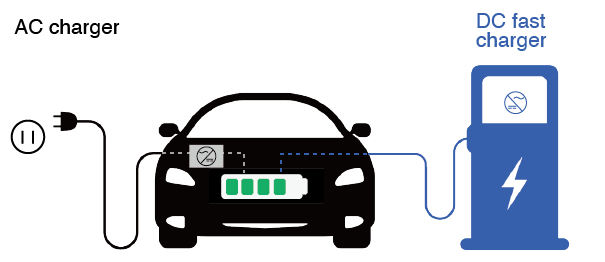

A battery electric vehicle (BEV) runs on a battery, which can be charged through AC or DC chargers. As shown in Fig. 1, an AC charger converts grid AC power to DC inside the vehicle, while a DC charger (EV fast charger) converts outside the vehicle, which is within the charger itself. Unlike an AC charger, a DC charger converts a higher voltage inside the charger, resulting in a high output capacity of DC power, making EV charging faster.

Fig.1: Example of AC and DC charging

Fig.1: Example of AC and DC charging

During the installation of the EV fast charger, a power quality inspection and AC-to-DC power efficiency measurement are performed to ensure correct operation. In this article, you will learn about the on-site power quality and efficiency measurement of an EV fast charger and the equipment required to do this inspection.

Measurement purpose

There are two purposes for the on-site measurement of power quality for EV fast chargers :

- 1.To check that the installed equipment does not receive and create any power quality issues.

- 2.To see if the EV fast charger works properly according to the specifications.

When installing the EV fast charger, it is important to verify that the power quality supplied to the equipment has no issues. The measurement result can also be proof that the power supply fed to the charger has no problem, the charger does not create any power quality issues during the charging process, and it is properly installed.

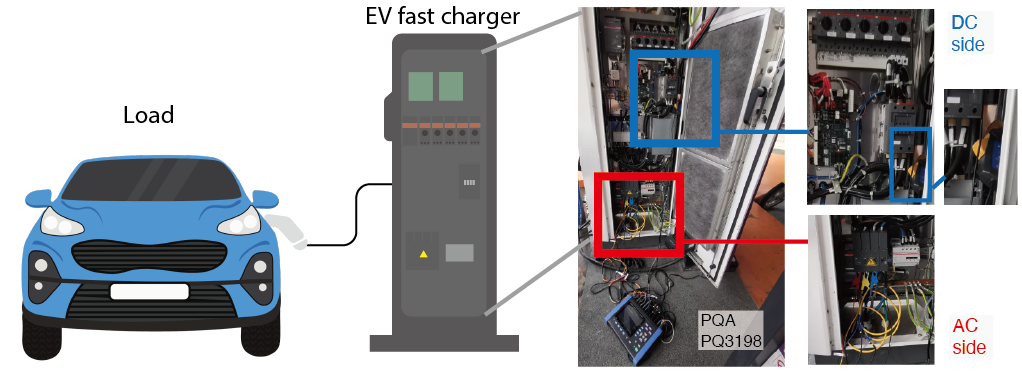

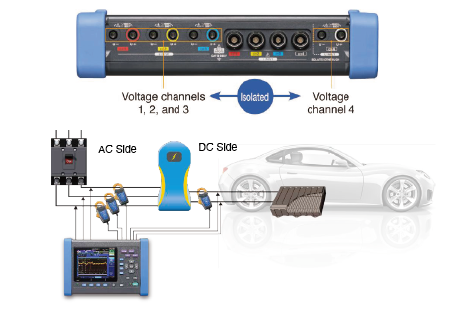

Here is one way to measure the power quality of EV fast chargers on-site. To conduct the measurement, an electric car is charged with the charger, which serves as a load, and the power quality analyzer is set to record the measurement data. Fig. 2 shows an example of how the connections for measurement are made. The DC charger's housing is opened, and the connections from the charger's circuit panels and the power quality analyzer are made. Connections are made both on the AC side, which is connected to the grid, and on the DC side, which is converted from AC grid power. Depending on the stage of charge (SOC) and the vehicle type, the measurement time could range from about 15 minutes to an hour.

Fig. 2 Example of measurement connections

Fig. 2 Example of measurement connections

Core measurement parameters evaluated during measurement

Depending on the purpose of the measurement, the parameters that are being focused on are different.

- 1. Power quality inspection:

- Power quality parameters such as voltage dip, swell, and interruption

- Harmonics and THD

- Power factor

- Frequency fluctuation

- 2. Specifications inspection:

- The grid AC voltage, current and power

- Converted DC voltage, current and power

- Power convertion efficiency (From AC to DC)

- The accuracy of the charger's power consumption calculation system

Take note that there could be more parameters that are being monitored during the inspection. This may differ according to the country's regulations, the EV charger's installer preferences, and the charger manufacturers.

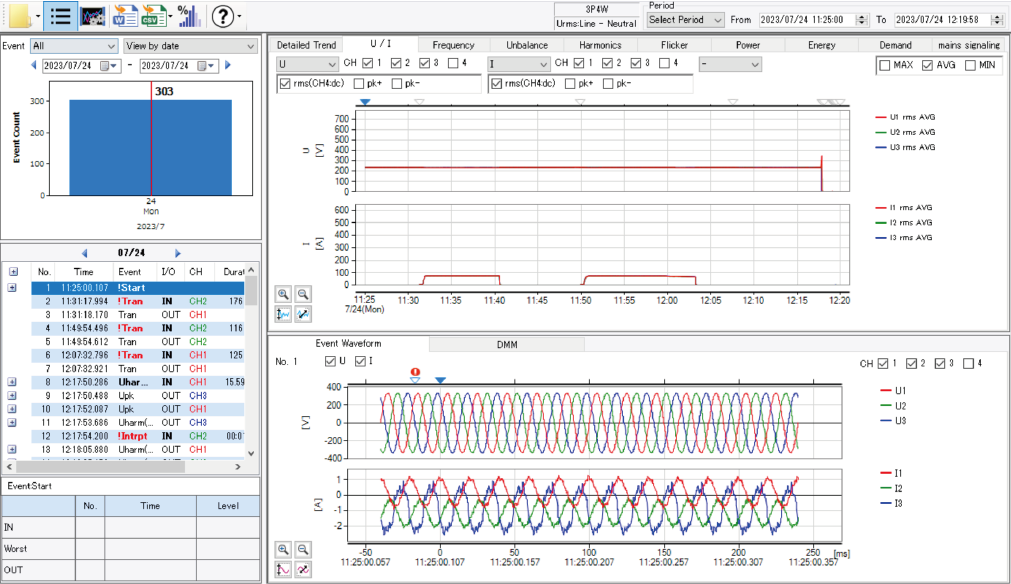

Measurement result sample

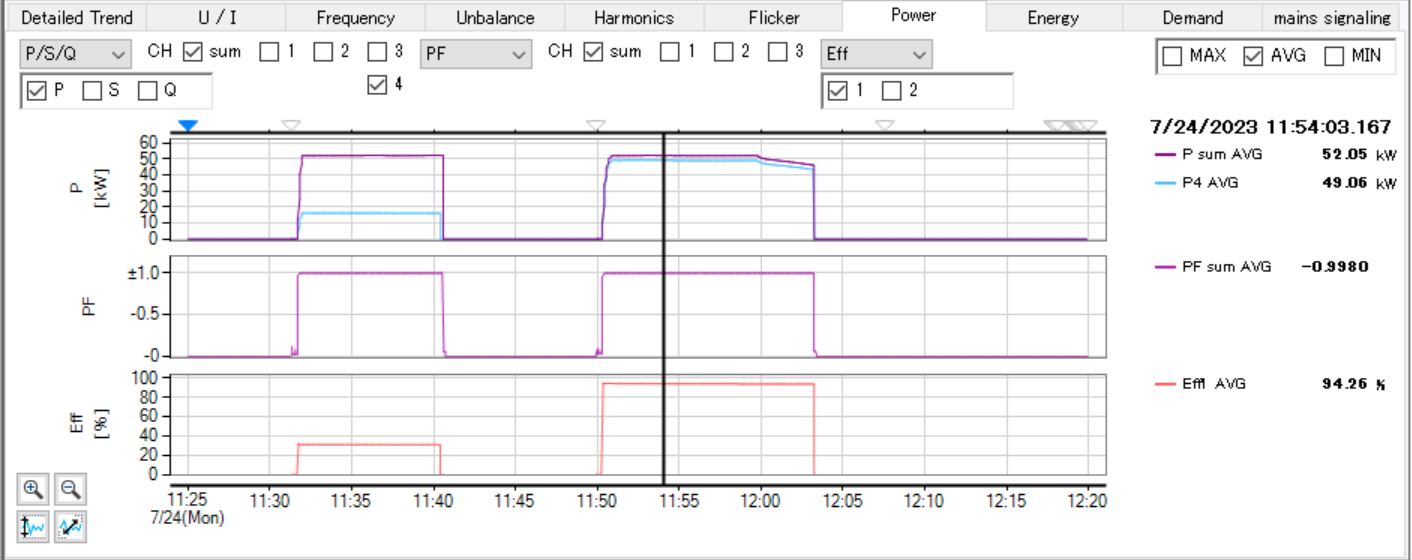

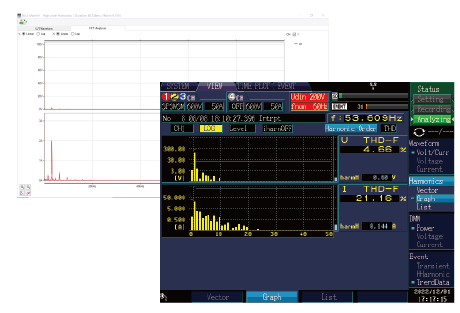

Table 1 shows an example of the specifications summary for an EV fast charger. Fig. 3 to Fig. 5 show a few screenshots of the measurement results for the charger conducted on-site.

Table 1 : EV fast charger specifications

| Parameters | Specifications |

|---|---|

| Input voltage range | 400 VAC +/-10 % (50 or 60 Hz) |

| THD in all operating points | less than 5.0 % |

| Efficiency | 93 % |

| Maximum output power | 50 kW |

Fig. 3 : Overview of measurement result

Fig. 3 : Overview of measurement result

Fig. 4 : AC and DC power, power factor, and power conversion efficiency

Fig. 4 : AC and DC power, power factor, and power conversion efficiency

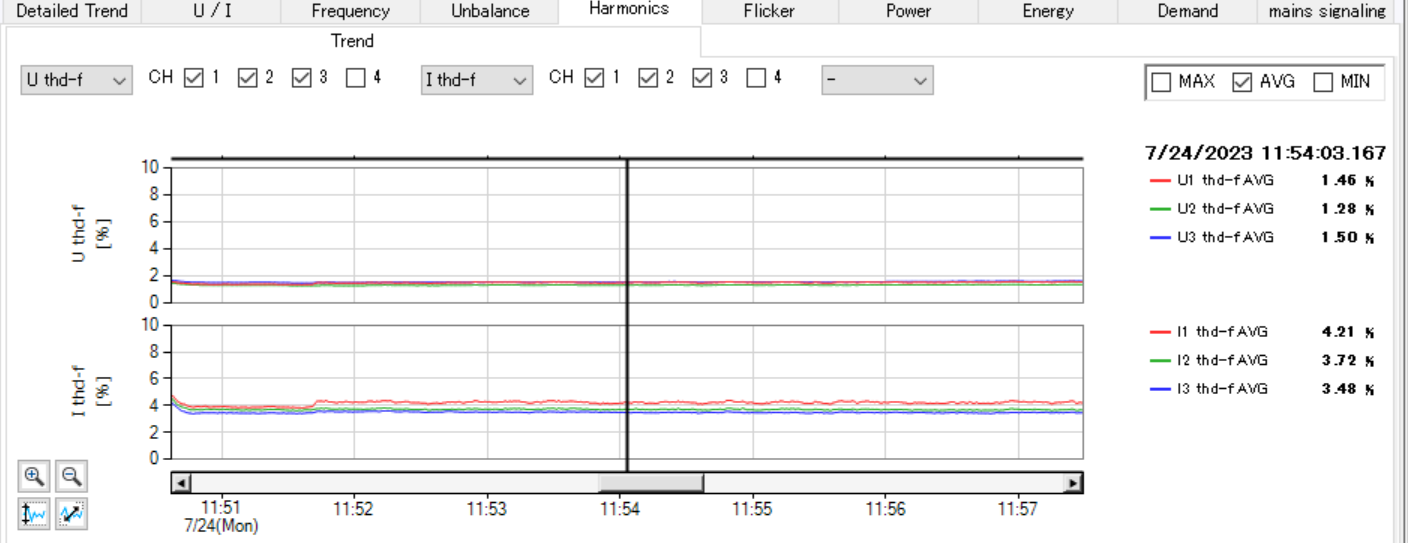

Fig. 5 : THD percentage

Fig. 5 : THD percentage

Measurement solutions from HIOKI

To evaluate the power quality and charging efficiency on-site of an EV charger, HIOKI recommends the power quality analyzer, PQ3198, because of its standard-compliance, the ability to perform two-circuit measurement, its harmonic measurement capability, an easy-to-setup interface, and wide range of available current sensors.

1. Standard compliance

The PQ3198 complies with the IEC 61000-4-30 Ed. 3 Class A standard. The standard classifies the measurement methods in AC power supply systems , as well as the capabilities of measuring instruments into 2 classes of A and S. As the Class A provides the more reliable power quality measurement, the PQ3198 is more reliable for resolving disputes and ensuring compliance with standards. A Class A certified power quality analyzer like the PQ3198 can provide trustworthy measurement results for capturing power quality parameters such as voltage dip, swell, interruption, frequency fluctuations and power measurement.

2. Two-circuit measurement

The PQ3198's fourth voltage channel is isolated from its first three voltage channels, which makes the instrument able to measure power quality and efficiency across two separate circuits safely. The instrument allows you to verify the quality of the input (AC) and output (DC) of an EV fast charger while simultaneously measuring power quality and efficiency between input and output.

3. Harmonics and THD measurement

Besides harmonics and THD measurements up to the 50th order, the PQ3198 is also able to capture the supraharmonic component (up to 80 kHz). By combining the analysis and reporting software (PQ One), FFT analysis of the supraharmonics component, and report creation of the measurement can be done in an instant.

4. Easy to Set up

The PQ3198 offers presets that suit your application. With these preset configurations, the instrument will automatically configure the recording parameters. Presets like EN 50160 let you evaluate whether data complies with the EN 50160 standard by analyzing it and generating a judgment based on voltage fluctuations during the trend interval (just as the standard specifies). You can also customize your measurement settings and save them to the instrument so that the same measurement can be done at different sites.

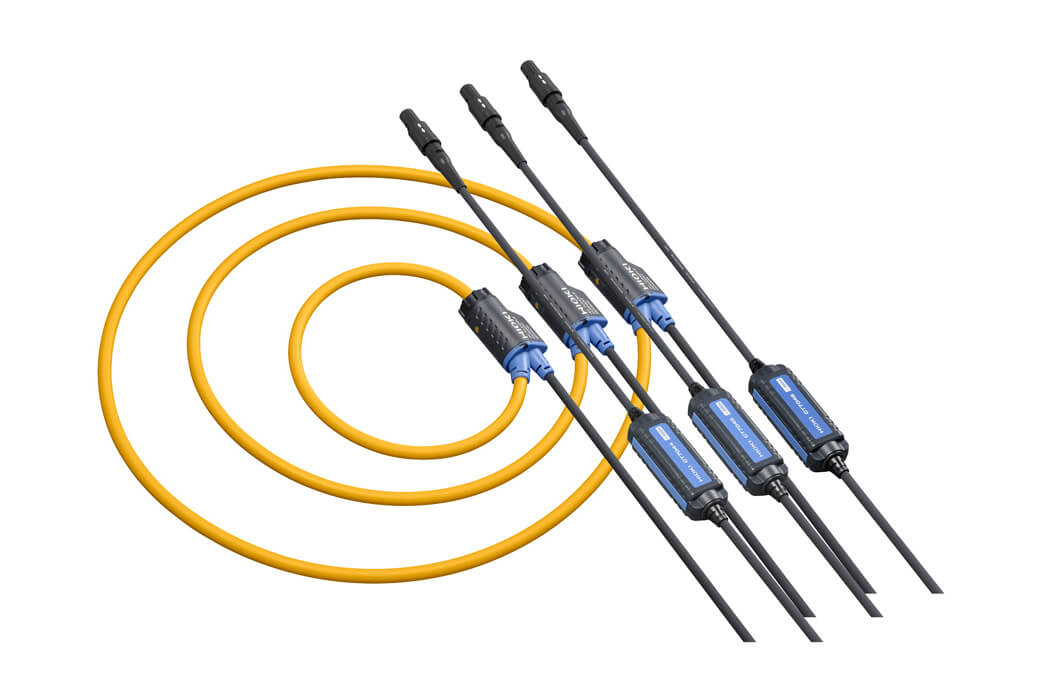

5. Wide range of sensors for better quality measurement

The flexible sensor CT7045 is ideal for measuring current in confined spaces, such as inside the charger, and its three ranges (50, 500, and 5000 A) make it best for measuring a wide variety of current. As for the DC side, we would recommend the AC/DC sensor, CT7736 (AC/DC 600 A). Since there is no need for an AC adapter to power our flexible and AC/DC sensors, the measurement is much smoother than other brands and requires less wiring.

Finally

Ensuring future mobility with quality charging infrastructure for electric vehicles can start with quality power in the EV charger. The HIOKI power quality analyzer will help you understand your power quality better. Check the PQ3198 product page or speak with our specialist for additional product information.