Efficient Ground Resistance Measurement Without Disconnecting Electrodes

Introduction

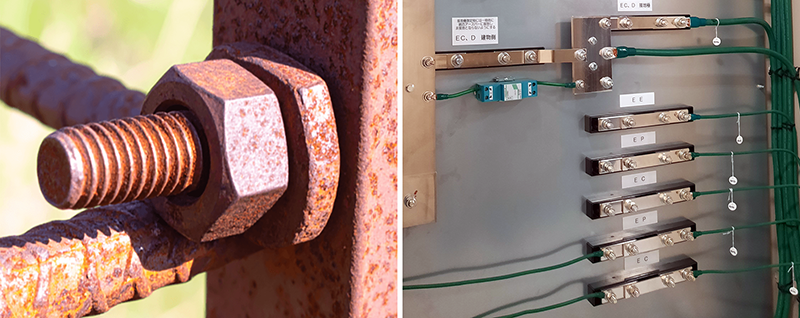

Ground resistance measurement is a critical task for ensuring the safety and reliability of electrical systems in industries like energy, construction, and rail. Traditionally, the 3-pole method requires disconnecting the ground electrode from the power system, a process that is both time-consuming and challenging, especially when electrodes are rusted or inaccessible.

Hioki’s innovative solution, the MEC (Measuring Earth with a Clamp ) function enables accurate ground resistance measurements without disconnection. This application note explores how the MEC function, integrated into the Hioki FT6041 Earth Tester, simplifies workflows, enhances safety, and boosts efficiency for technicians and maintenance professionals.

Challenges of Traditional Ground Resistance Testing

The 3-pole method, a standard for ground resistance measurement, requires disconnecting the ground electrode from the power system. This disconnection and subsequent reconnection are labor-intensive and disrupt operations. Electrodes that have rusted may make disconnection impossible. For technicians and their managers, these inefficiencies translate to higher costs and downtime, particularly in critical infrastructure like power utilities or rail systems.

The MEC Solution: Ground Testing Without Disconnection

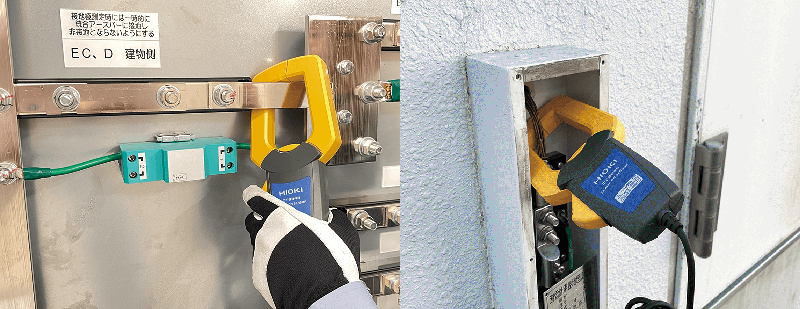

Hioki’s FT6041 Earth Tester, equipped with the MEC function, eliminates the need to disconnect ground electrodes. By using a clamp sensor, the MEC method measures the current flowing through the target ground electrode (R1) while accounting for the combined resistance of parallel electrodes (Rn). This approach isolates the resistance of the target electrode, delivering accurate results without the hassle of disconnection. The clamp sensor’s design ensures ease of use, even in confined spaces like earth boxes or on busbars, making it an ideal tool for on-site maintenance.

Measurement Principle

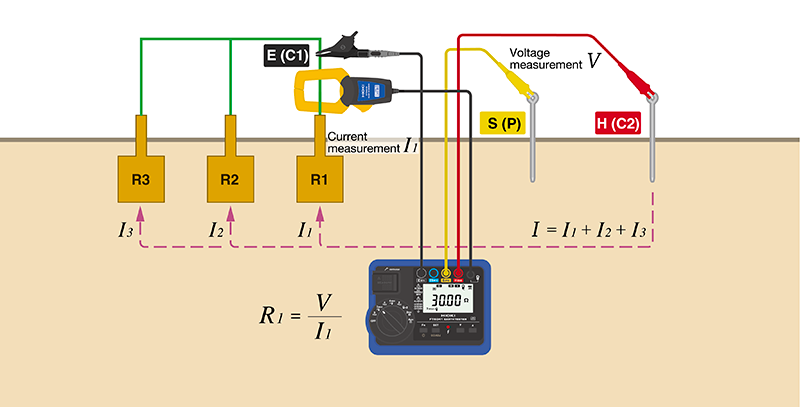

When a ground electrode cannot be disconnected, traditional measurements capture the combined resistance of R1 and Rn, which are connected in parallel (Fig. 1). The MEC function addresses this by clamping directly onto the target electrode to measure only the current flowing through R1. By isolating this current, the FT6041 calculates the true resistance of the target electrode, ensuring precision even in complex grounding systems.

Fig. 1: Diagram illustrating parallel ground electrodes (R1 and Rn) and the MEC clamp sensor isolating R1’s current for accurate resistance measurement.

Step-by-Step Measurement Procedure

To achieve highly accurate ground resistance measurements with the FT6041, follow these steps:

1. Set the FT6041 Dial: Rotate the main unit dial to “4pole + Clamp” mode to activate the MEC function.

2. Connect Measurement Cords: Attach the black and blue measurement cords to the ground electrode under test.

3. Insert Auxiliary Earth Stake (S): Place an auxiliary earth stake at least 10 meters from the ground electrode and connect the yellow measurement cord.

4. Insert Auxiliary Earth Stake (H): Place a second auxiliary earth stake at least 10 meters from the first (S) stake and connect the red measurement cord.

5. Begin Measurement: Press the “MEASURE” button to start the test and record the resistance value.

This streamlined process minimizes setup time and ensures reliable results, even for operators with basic knowledge of ground resistance testing.

Benefits of Hioki’s Clamp Technology

Hioki’s advanced clamp technology sets the FT6041 apart, offering unmatched precision and usability:

• High Sensitivity: The clamp sensor accurately measures currents as low as 10 µA, enabling reliable low-resistance measurements (1 Ω or less).

• Versatile Design: The clamp’s shape allows easy attachment in tight spaces, such as earth boxes or busbars, enhancing on-site efficiency.

• User-Friendly Operation: The FT6041’s intuitive interface and robust clamp design simplify testing.

These features make the FT6041 an indispensable tool for maintenance teams seeking to optimize their workflows while maintaining high accuracy.

Applications Across Industries

The FT6041 with MEC function is tailored for industries where grounding is critical, including:

• Energy (Power & Utility): Ensures safe and efficient grounding for power distribution systems

• Construction: Verifies grounding integrity in buildings and infrastructure projects

• Rail: Supports maintenance of grounding systems in rail networks, minimizing downtime

Operators and their managers benefit from reduced labor and faster testing, while Hioki’s distributors can confidently recommend the FT6041 as a reliable, cutting-edge solution.

Conclusion

The Hioki FT6041 Earth Tester, with its MEC function, transforms ground resistance testing by eliminating the need to disconnect electrodes. This solution saves time, reduces operational disruptions, and ensures accurate measurements, even in challenging environments. By adopting the FT6041, technicians and maintenance teams can enhance efficiency and streamline workflows across energy, construction, and rail applications. To learn more about the FT6041, download this application note or visit the FT6041 product page for detailed specifications and resources.