Operational Testing of Engines Used in Outboard Motors

An Engine is the Heart of an Outboard Motor

Outboard motors are propulsion devices for boats that integrate a propeller with a drivetrain including an engine, gears, a clutch, and a driveshaft. Engines used in outboards generate a large amount of power despite their compact size. Since they’re required to deliver excellent reliability and durability, multifaceted evaluation using a variety of sensors is a necessary part of the development process. Motor failures at sea can be disastrous for the crew and passengers on board, so it is critical that engine developers verify the integrity of their products before they are mass produced and ultimately installed.

Multi-channel Testing is Indispensable for Next Generation Engines

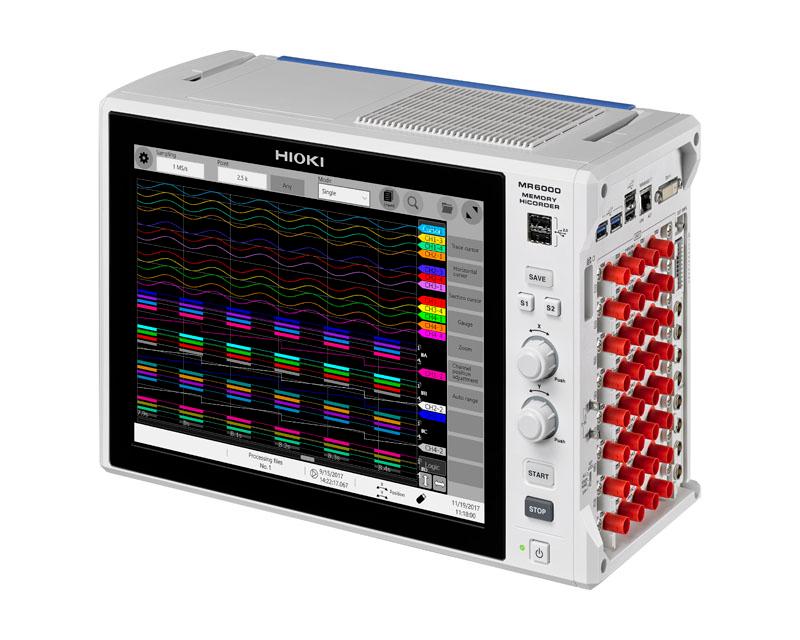

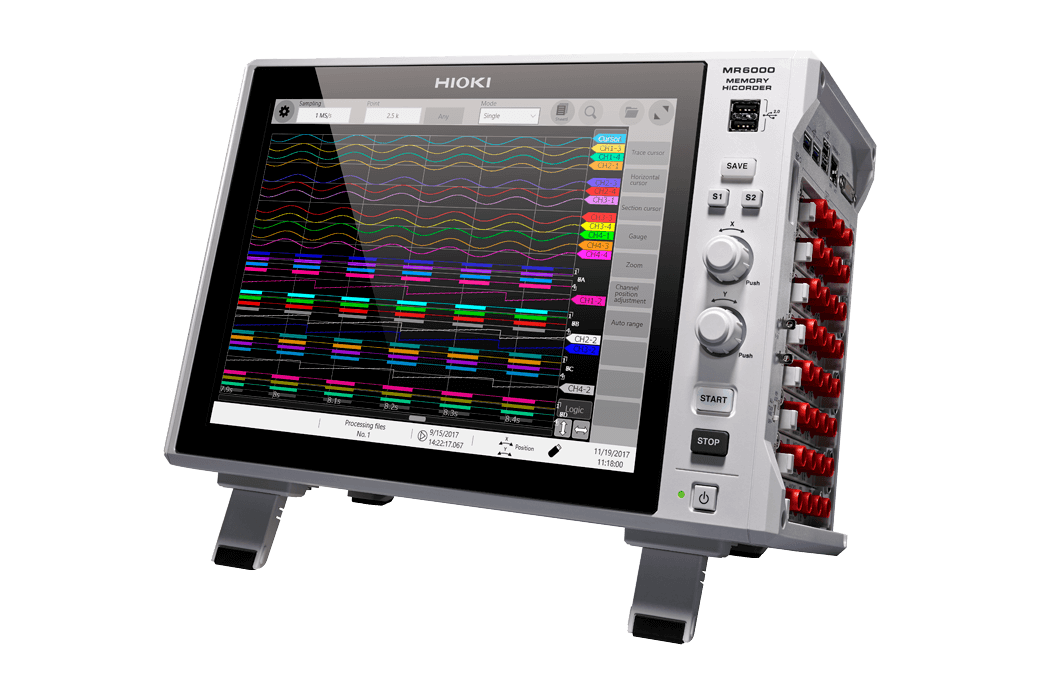

High-speed sampling measurement and long-term recording are the key operational testing capabilities utilized in the development of outboard motors. Recent outboard motors not only provide the horsepower to push the tide while minimizing size and weight, new regulations around the world, especially in the more seafaring regions such as Australia, US and Europe, are also calling for more stringent exhaust emissions. The Memory HiCorder MR6000 is the one-stop solution uniquely capable of meeting these application needs.

Key Points

- Pair the MR6000 with the High Speed Analog Unit U8976 to measure control signals of sub-microsecond duration, which have traditionally been checked using an oscilloscope. The captured signals are instrumental for investigating the causes of malfunctions by measuring noise waveforms that are superposed on control signals.

- Connect the MR6000 with a diverse array of sensors, including temperature, RPM, voltage, and current, across multiple channels, to analyze temperature fluctuations, power, electrical characteristics, ventilation, cooling capabilities, etc., while in operation, and all at the same time in order to determine the effects one may have over the other.

- 8 plug-and-play slots let you install 7 units of the Analog Unit 8966 to capture output from a variety of sensors across 14 channels simultaneously, dramatically decreasing the number of instruments needed for multi-signal testing as well as the time needed to plot all the data together on a single time axis for analysis

- Motor endurance is one of the key selling points of outboard motors. Search and rescue boats can be at sea for hours, and motor failure is not an option for life-saving missions. With the MR6000’s real-time save function, you can meet endurance testing conditions with the ability to record data over extended periods of time onto the SSD Unit U8332.

Sensors sold separately. See the respective manufacturers’ websites for more information.