Data Acquisition and Assessment in Railway Car Trial Runs (Train)

As the globe moves toward efforts of reducing carbon emissions, more focus has been put on public transit. One of the most low-carbon form of public transportation is the railway. That is why R&D and testing of new and old trains are not experiencing continued demand but a sort of renaissance of sorts under the veil of sustainability and environmentalism.

In this application note, we will take a look at the data acquisition process during a trial run of a railway car and the equipment that suits this application.

Key aspects of data acquisition for railway car trial runs

Since trains run on rails manufacturers and railway companies need not test traditional steering but can focus on testing in two conditions: acceleration and deceleration. For acceleration, efficiency is a focus of testing, while for deceleration, it’s safety and effectiveness of braking. Further, vibration control in both conditions are tested to improve and maintain car durability as well as passenger comfort. These things are tested during “trial runs” on actual rail routes after production by manufacturers and by railroad companies before starting commercial operation.

In trial runs, the following concerns are checked and the measurement data is kept for record.

- 1.Will the railway car meet all the performance specs on the actual routes of the railway company?

- 2.Is there any abnormality in the operation on the test routes?

- 3.Is it possible to stop within a predetermined distance while driving safely and controlling the train speed?

Purposes and types of data acquired during the trial run

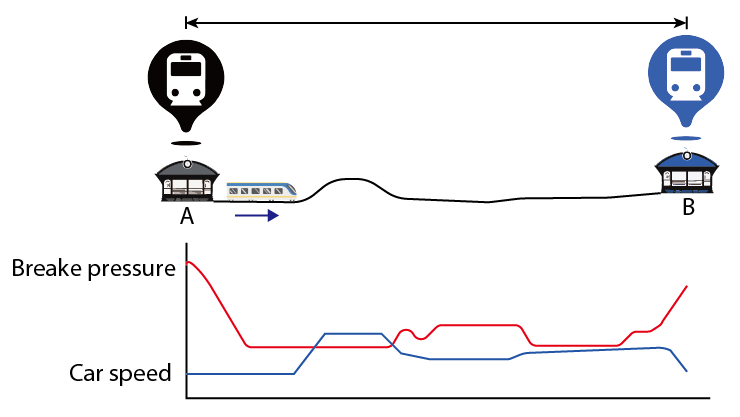

The train manufacturers and railway companies both will conduct the following tests before starting commercial operation. Fig. 1 illustrates a test run from station A to B (ranging from several minutes to 20 minutes and several kilometers to 50 kilometers). Table 1 provides an example of the parameters being checked and their respective purposes.

Fig. 1 Test run from station A to B

Fig. 1 Test run from station A to B

Table 1: Types of data acquired and purposes

| What to check for | Measurement parameters |

|---|---|

| Safe brake operation | Brake pressure, speed (RPM) |

| Abnormal vibrations | In every situation Record the vibrations in three directions, as in back-and-forth, side-to-side, and up-and-down, using a triaxial accelerometer sensor |

| Power requirement compliance | Voltage, current, and power provided to the drive motor |

The route that the train takes from station A to station B must provide significant variation in distance, travel duration, and road height.

Factors considered when acquiring data in railway car trial runs

A trial run has many factors that need to be considered when performed:

- Since test runs must be done on tracks in between busy commercial train traffic, it’s a race with time to properly finish the test without hitch. Because of this, each test cannot be repeated many times, making it necessary to record many parameters simultaneously.

- The railway car itself is essentially a large enclosure, multiple points must be measured with respect to the traveling direction, such as the front seat, the rear seat, and the connecting section.

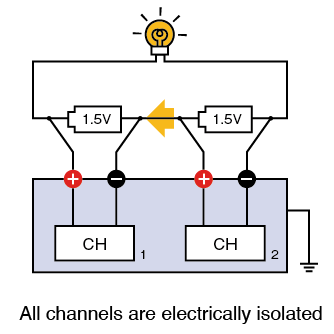

- For measuring the power systems, the technician needs to measure multiple points that have different potentials to ground. To do this, each input of the instrument needs to be isolated. This also has an added benefit of being safer for both the instrument and the user.

- To understand the shaking condition during the test run in detail, it is also important to use equipment with a high input resolution so that weak vibration levels can be measured with high accuracy.

- For vibration measurement, high-speed sampling (about 10,000 points per second) and long-term recording are required.

- For measuring physical quantities such as vibration, sensors and wiring are needed to collect the data.

Data acquisition solutions from HIOKI

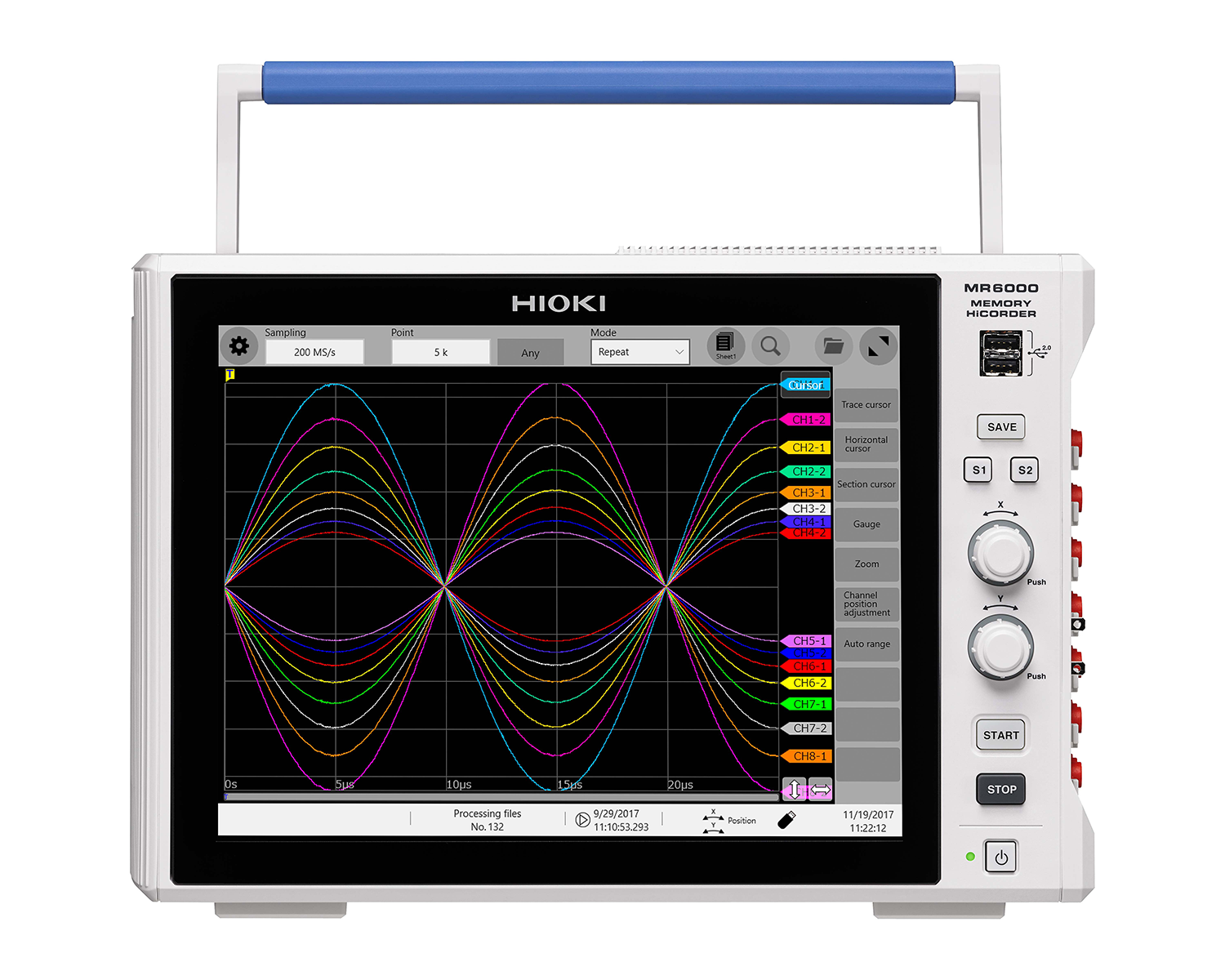

For data acquisition purposes in this application, HIOKI recommends the memory hicorder, MR6000. MR6000 is a data acquisition instrument that allows you to view and record various kinds of signals and data simultaneously. It offers an extensive line of modules (or units) for detecting a wide range of phenomena. Here are the three reasons why Hioki’s HiCorder is the ideal choice for trial-run testing.

- 1.Variety of measurement parameters

- 2.Easier and safer with Hioki-isolation

- 3.Advanced data handling

1. Variety of measurement parameters

Flexibly choose from various units (or modules) for electric and physical phenomena. Here are some examples of units (or modules) that are ideal for this application.

| Unit | Purpose |

|---|---|

| Measurement of voltage and current from the VVVF inverter to the motor for driving | |

| U8979 Charge unit | Vibration measurement |

| U8969 Strain unit | Strain, pressure, and stress measurement |

| 8970 Frequency unit | Speed |

Even for parameters not mentioned above, there are other units such as temperature unit. Not to mention, the recording across multi-channel can be done simultaneously with a resolution that matches the high sampling speed (up to 200 MS/s) and accuracy necessary. This allows you to capture multiple data streams with precision and efficiency, potentially saving time and ensuring data accuracy when acquiring data for a trial run of a railway car.

2. Easier and safer with Hioki-isolation

The connections between analog input channels and between the input channel and the main unit are fully isolated, ensuring maximum convenience. This design eliminates the need for voltage-to-ground equalization between inputs. The isolation between inputs give Hioki the edge in safe measurement as it protects both the instruments and technicians from unforeseen high voltages.

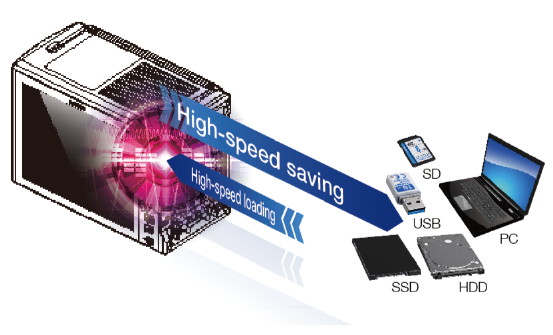

3. Advanced data handling

The MR6000, with its impressive storage capacity of 1 Gword, is ideal for vibration measurements with high resolution and extended monitoring periods. Thanks to this extensive storage, you can easily collect data over extended time frames. Additionally, the instrument also allows you to transfer measurement data directly to your PC by using the FTP sending function together with the real-time save function. This makes it easier to observe data after the measuring process.

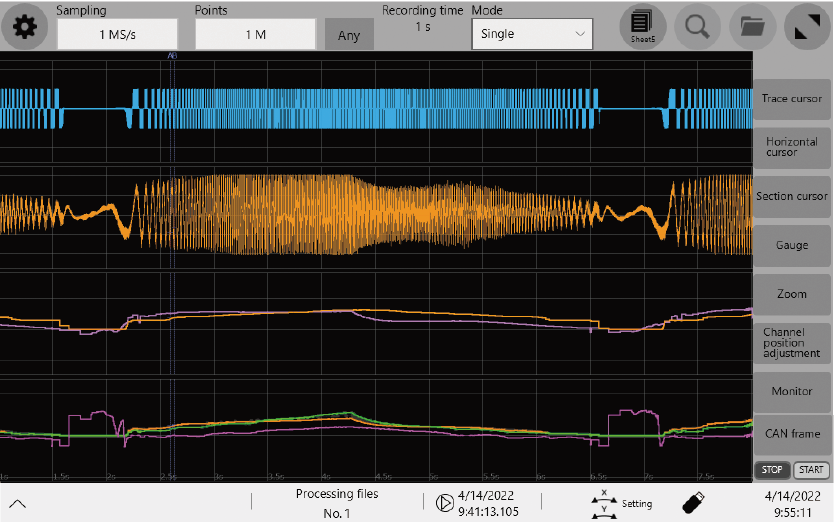

Fig.2 shows an example of data recorded with the MR6000.

Fig.2 Example of data recorded with the MR6000

Fig.2 Example of data recorded with the MR6000

Finally

Trains will not only remain an important part of life but is expected to grow in prominence as the world focuses on sustainability and decarbonization. This also means that test runs of trains will increase, as will the importance for measuring instruments that support more accurate and effective data acquisition. We hope our outline of railway car test runs were informative and that we were able to convince the reader to consider Hioki’s Memory HiCorder as an instrument ideal for the job. For more information on the HiCorder, check out the MR6000’s product page, or feel free to contact one of our specialists to learn more about the product. We at Hioki look forward to working with you for a more sustainable and profitable future.