Lithium-ion Battery Insulation Resistance Testing

What is insulation resistance testing of lithium-ion batteries?

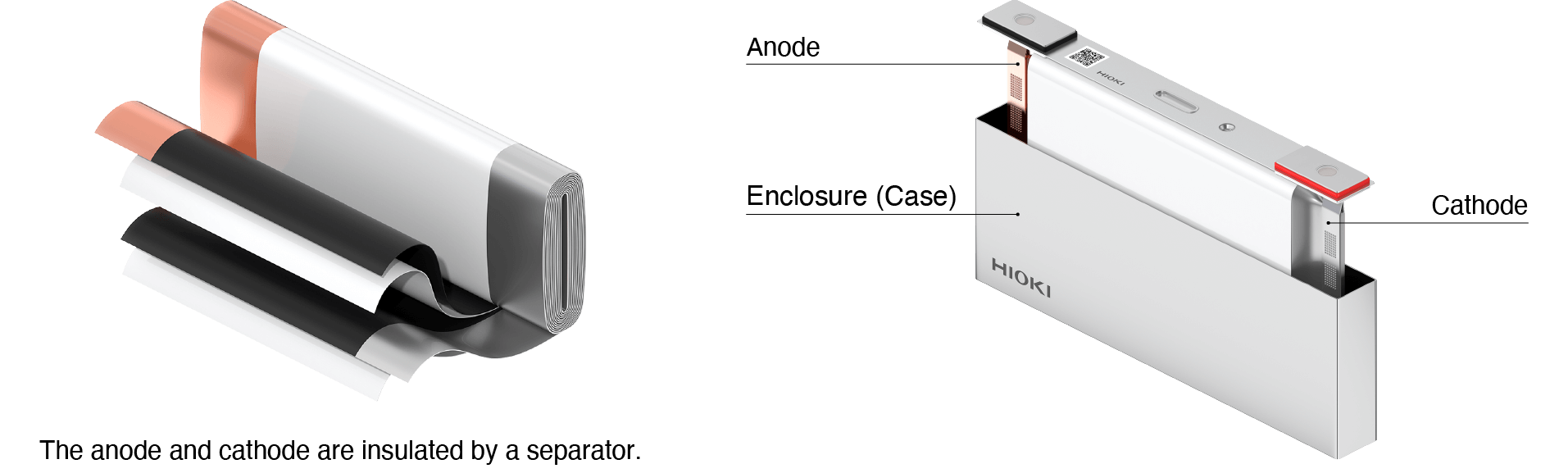

Insulation resistance measurement serves as an important test for detecting defects on lithium-ion battery (LIB) cell production lines. Structurally, it’s necessary to keep the anode and cathode, as well as the electrodes and enclosure (case), insulated from each other. Failure to keep those components properly insulated—in other words, insufficient insulation resistance - could lead to a risk of ignition or fire accidents.

While insulation defects can be caused by a variety of factors, testing in the battery cell production process focuses on detecting defects caused by internal shorts.

When to test insulation resistance

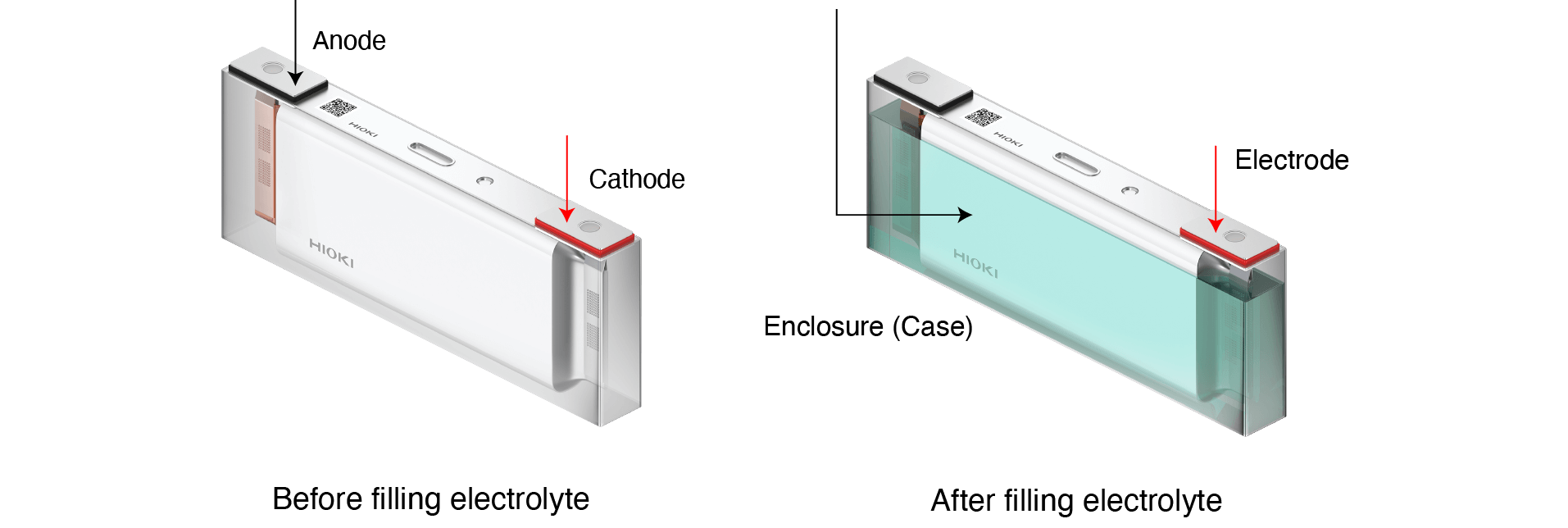

Battery cell insulation resistance testing is generally carried out as follows (*1):

- Before filling electrolyte into battery cells:

DC voltage is applied between each cell’s anode and cathode, and the insulation resistance is measured.

- After filling electrolyte into battery cells:

DC voltage is applied between each cell’s electrodes and enclosure, and the insulation resistance is measured.

- *1:Test timing and measurement locations vary by manufacturer.

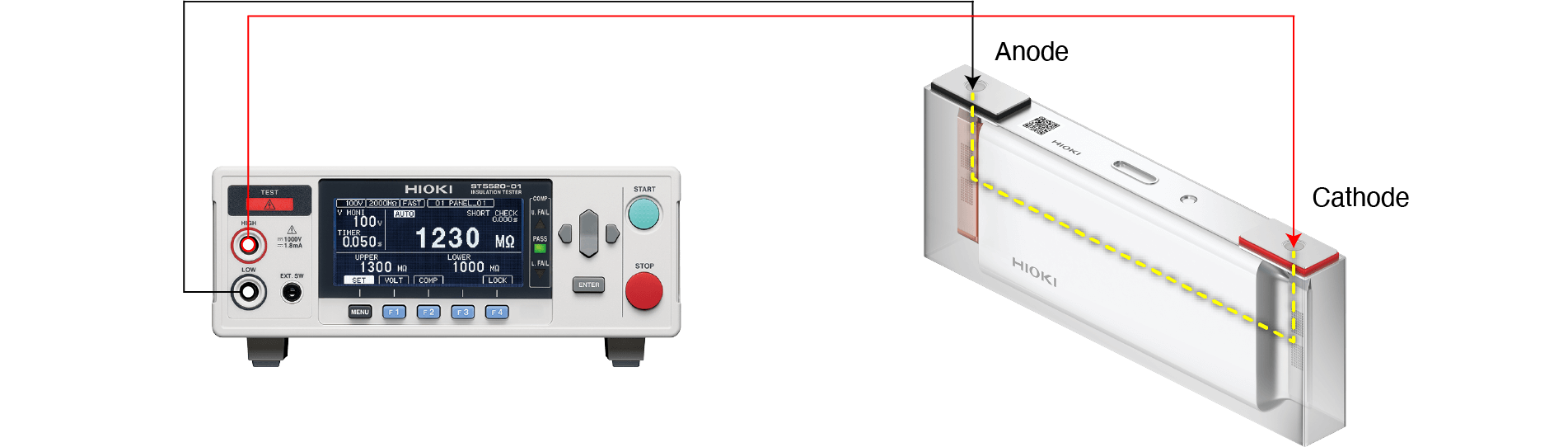

How to measure insulation resistance

Battery cell insulation resistance is measured using an insulation resistance tester or insulation tester, designed specifically for high-insulation measurement. Insulation resistance meters apply a DC voltage. They detect the minuscule current that flows when this voltage is applied and use it to calculate the resistance value. Insulation resistance meters have a built-in, high-sensitivity ammeter that can accurately detect minuscule currents.

Key considerations when choosing an insulation tester

The following considerations should be taken into account when choosing an insulation tester:

- Insulation resistance value measurement range and accuracy

- Test voltage

- Charging current

- Automatic discharge function

- Contact check function

Insulation resistance value measurement range and accuracy

Insulation testers that are designed specifically to measure high resistance values are used in cell insulation resistance testing. The reference (resistance) values used to classify cells as defective or non-defective depend on the battery being tested. Be sure to check the reference values for the cells being tested and the insulation tester’s measurement range.

Test voltage

The test voltage is the voltage that the insulation tester applies to the cell under test. The appropriate test voltage varies from battery to battery. DC voltage of 100 V to 200 V is generally applied in battery cell insulation resistance testing. Recently, it has become more common to use a low voltage such as 5 V or 50 V.

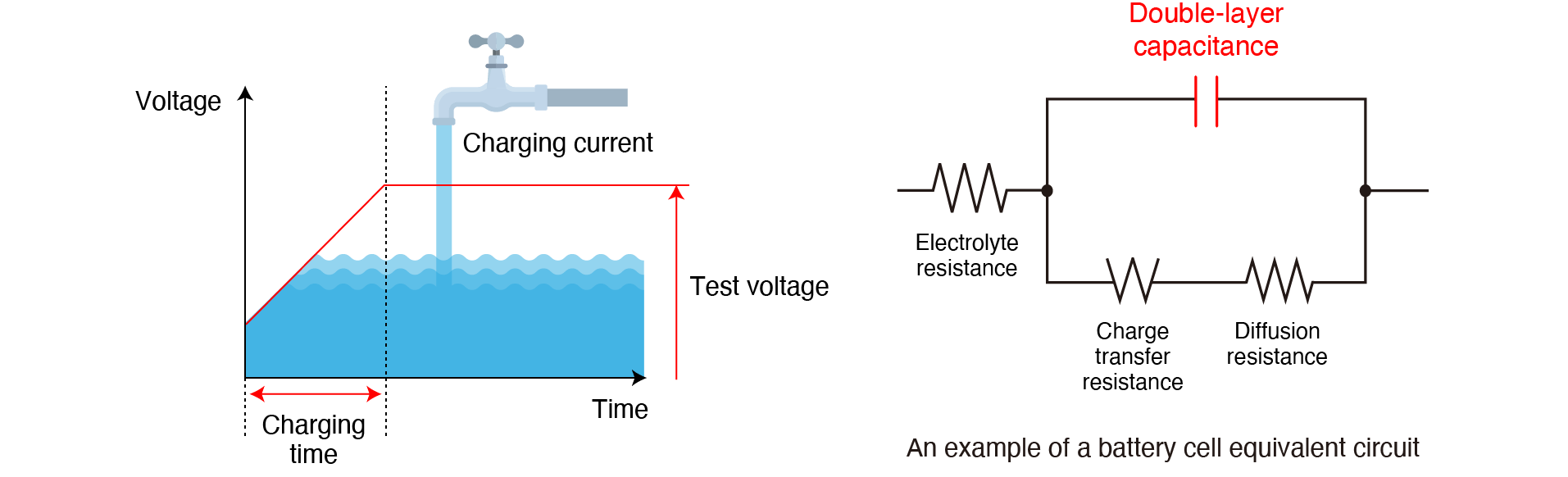

Charging current

Charging current is an important consideration from the standpoint of shortening test times. The charging current indicates the magnitude of the current output by the insulation tester. Due to their structure, battery cells incorporate a double-layer capacitance. Consequently, it takes time for the voltage to rise to the set test voltage (due to the capacitance charging time). Since larger charging currents translate into shorter charging times, you can reduce test times by choosing an instrument that’s able to output a larger current.

Automatic discharge function

An automatic discharge function serves to discharge the charge that accumulates in the battery. When the test voltage is applied, the battery’s double-layer capacitance accumulates a charge. If the battery is connected to test equipment in the next process, for example, while it is still charged, the equipment could be damaged. Insulation testers use either the resistance method or the constant-current method to provide discharge functionality. When testing battery cells, the constant-current method offers faster discharging, which translates into shorter test times.

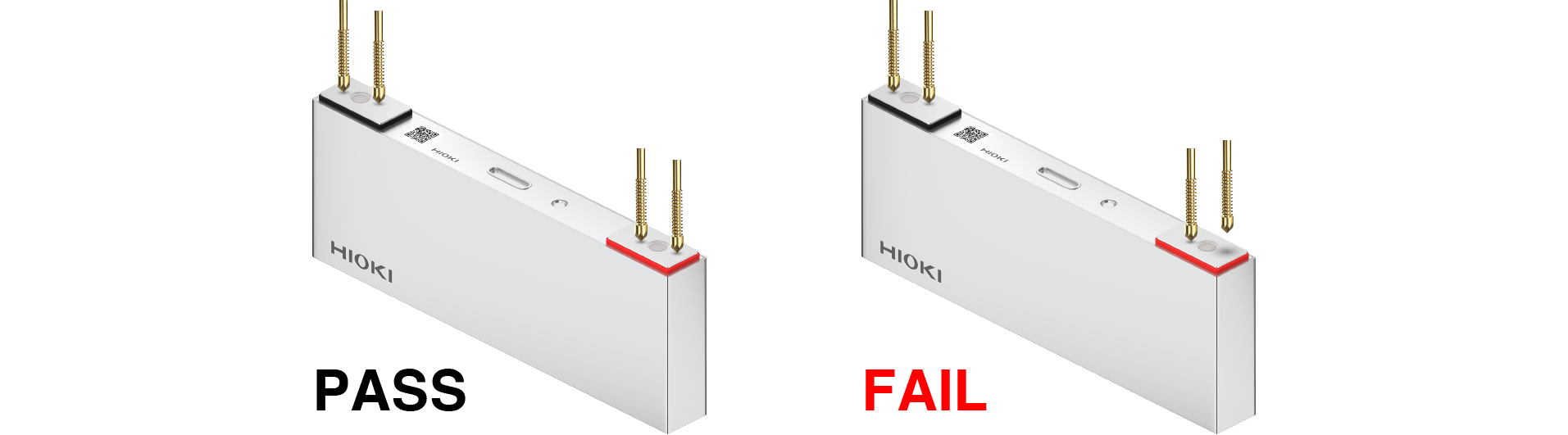

Contact check function

If you need to carry out highly reliable testing, it’s important for the instrument you choose to provide a contact check function. This function checks the state of contact between the measurement probes and the object under measurement. If the measurement probes are not in contact with the object, the tester could erroneously conclude that the object is non-defective (since the insulation resistance value will be high if no contact has been established).

Insulation testers from Hioki

Hioki’s insulation testers working at by battery manufacturers around the world. The following models are used in insulation resistance testing in battery cell production processes

| Product model | BT5525 | ST5520 | SM7110 | SM7120 |

|---|---|---|---|---|

| Measurement range | 0.050 MΩ to 9999 MΩ | 0.002 MΩ to 9990 MΩ | 0.001 MΩ to 10000 PΩ | 0.001 MΩ to 20000 PΩ |

| Test voltage (DC) | 25 V to 500 V | 25 V to 1000 V | 0.1 V to 1000.0 V | 0.1 V to 2000.0 V |

| Basic accuracy | ±1.5% rdg. ±2 dgt. | ± 5% rdg. | ± 0.53% rdg. ±12 dgt. | ± 0.53% rdg. ±12 dgt. |

| Measured current | 50 µA to 50 mA | 1.8 mA | 1.8 mA to 50 mA | 1.8 mA to 50 mA |

| Automatic discharge | Constant-current discharge | Constant-current discharge | Constant-current discharge | Constant-current discharge |

| Contact check | ✔ | ✔ | ✔ | ✔ |