News Jun. 07, 2022 Directly Measure the Electric Properties of Battery Slurries

Build Better Battey Cells Faster

Have you been in search of the perfect technology to analyze the electrode slurry? When it comes to batteries, Hioki offers a variety of unique tools to help you build better batteries faster.

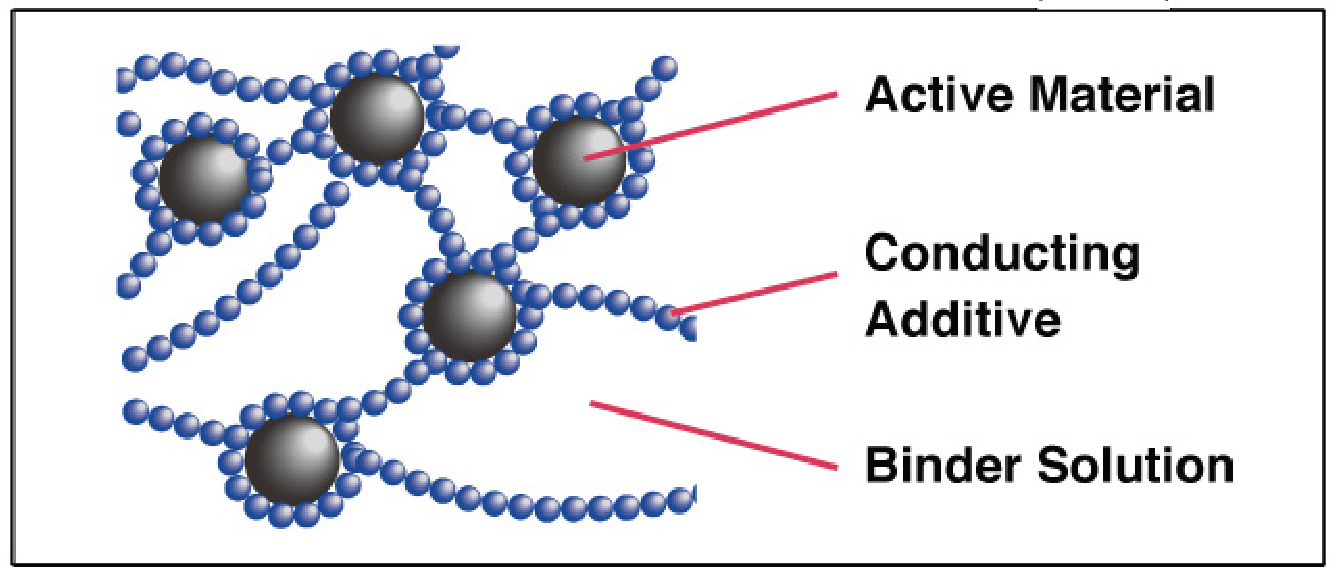

What is a slurry and how is it used? The slurry is one of the most important parts of a lithium-ion battery. It is a thick, black liquid that is used to coat aluminum and copper foils. The coated foils, aka. electrode sheets are rolled up to form the lithium-ion batteries. A battery slurry consists of 4 ingredients: active materials, polymer binders, conductive agents, and solvents.

Figure 1: Main components of a battery slurry.

The performance of a finished battery depends largely on the quality of the slurry. In a high-quality slurry, the conductive agents form a network in which the active material is embedded. A high-quality slurry needs to have two properties: 1) exactly the right amount of ingredients and 2) the slurry needs to be mixed in exactly the right way. If you stir too little, the ingredients are not well distributed, stir too much and particles clump together the agglomerate.

Up to now, battery researchers can only measure the mechanical properties of a battery slurry. Standard rheological testers measure properties like dynamic shear viscosity and do not give information about the electrical properties of a battery slurry.

HIOKI’s Slurry Analytical System measures three electrical properties of a battery slurry:

1) DCR, total electrical resistance, 2) Ratio, degree of network development, and 3) Uniformity, i.e. the degree of material dispersion.

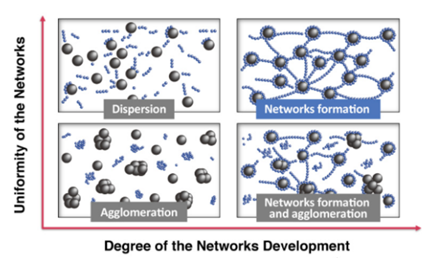

Figure 2: Electrical properties of a battery slurry. The optimal slurry has high degree of networks development and high degree of uniformity.

Figure 2 shows the degree of network development on the horizontal axis and the uniformity of the networks on the vertical axis. The perfect battery slurry will have a high degree of uniformity and a high degree of network development at the same time. With the HIOKI Slurry Analytical System researchers and development, engineers can optimize the constituents of the slurry and the amount and type of mixing to quickly identify the optimal point.

Figure 3: The HIOKI slurry analysis software is a cloud-based tool that identifies electrical properties of a battery slurry.

Hioki’s Slurry Analytical System consists of Hioki IM35360-series LCR meter, SA9001 electrode cells, and SA9002 test fixture. After mixing a slurry candidate, a battery researcher uses the SA2622 measurement software to acquire the impedance properties of the slurry sample. Based on this measurement, the cloud-based software SA2631 identifies the electrical parameters of the slurry. The whole test sequence takes less than a minute.

If a researcher cannot directly measure the electrical properties of a slurry, he/she needs to fabricate a complete battery cell and perform electrical tests on the cell. This process includes a multitude of process steps such as coating, drying, and calendaring electrode sheets and ultimately assembling a functional battery. With the Hioki Slurry Analytical System battery researchers reduce the time it takes to characterize a slurry from days to minutes. Battery developers can run many design skews in a short time to fine-tune slurry composition and mixing parameters and ultimately build better battery cells faster.