News Mar. 15, 2023

Fireproofing your Lithium-Ion Battery Cells: Powerful Detection Methods You Need To Know

Detection methods for lithium-ion battery cells containing ignition factors

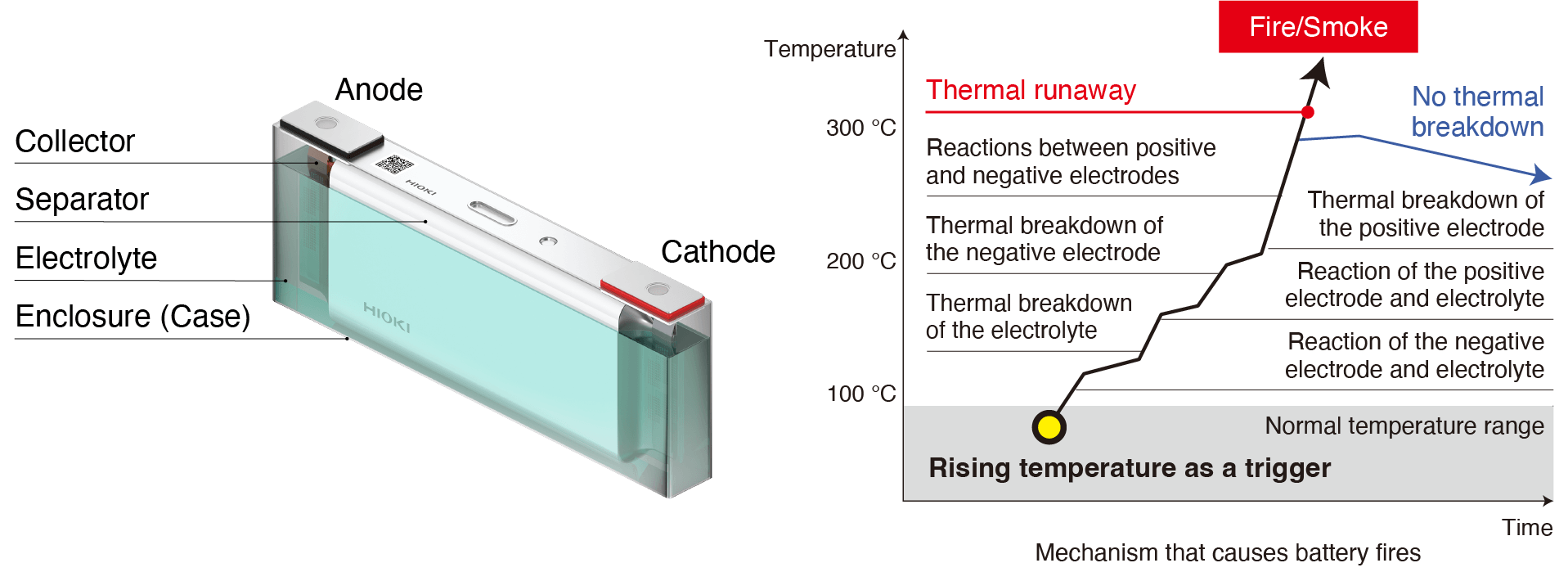

Ensuring battery safety and quality control is crucial to prevent potential accidents such as a fire caused by battery degradation. It is imperative to enhance testing techniques to avoid the release of defective batteries into the market.

Battery Measurement Handbook: Fundamentals and Applications

The batteries that are utilized in electric vehicles need to have an exceptionally high level of performance. The requirements placed on these batteries correspond to various characteristics of the automobile. Here are some examples:

- Long-distance driving: High energy density (high capacity in a compact, lightweight footprint)

- Fast charging: The ability to charge using large currents (exceptional high-current characteristics)

- Extended use: Long battery service life (improved performance in the face of repeated charge/discharge cycles)

- Improved safety: Resistance to combustion (protective functionality provided by prevention of internal battery short-circuits, BMS ICs, etc.)

- Lower vehicle costs: Limitations on material prices and high productivity (development of inexpensive materials and improvements to yields)

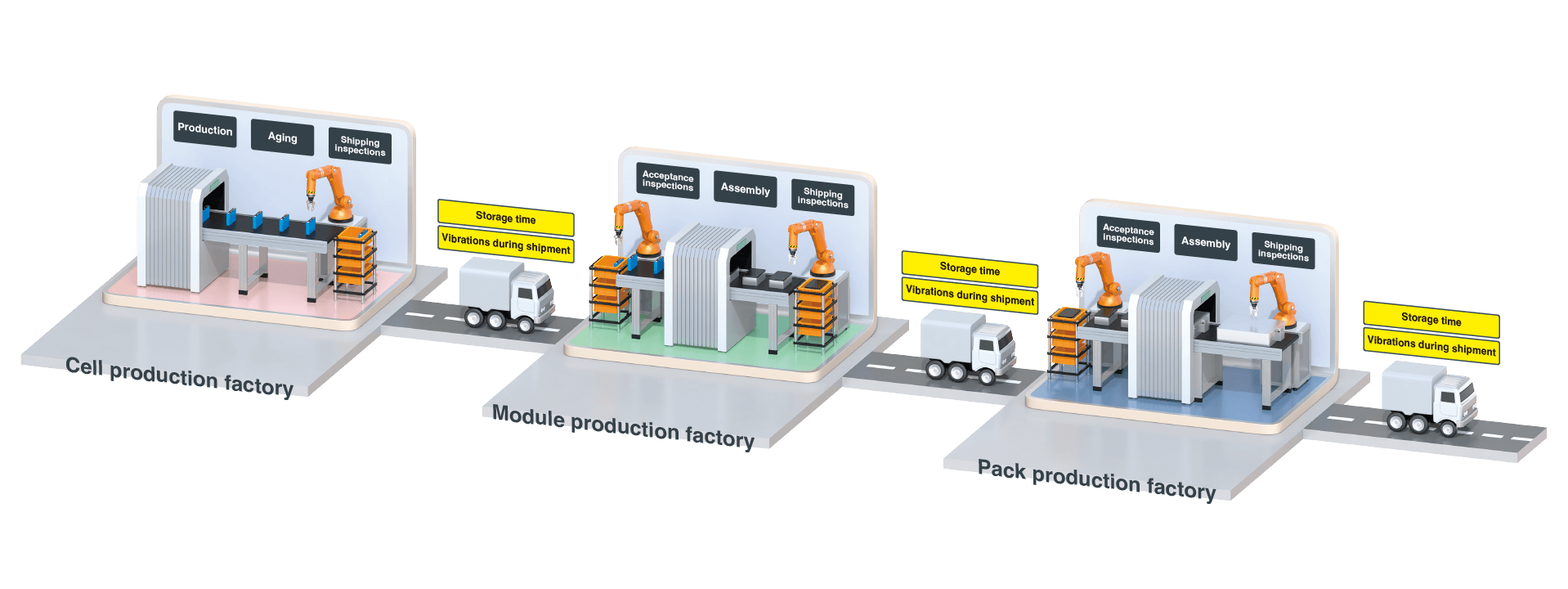

To achieve the battery properties shown above, it is crucial to conduct various measurements and tests throughout each stage of the battery manufacturing process to ensure the quality of each step. The handbook presented here outlines important factors to consider when choosing measurement and testing equipment that is crucial for assessing the effectiveness of materials, manufacturing processes, and end products, primarily centered around our solutions.