FIT-LINE INSPECTION DATA CREATION SYSTEM UA1780

Data Creation Software for Populated Board Testing

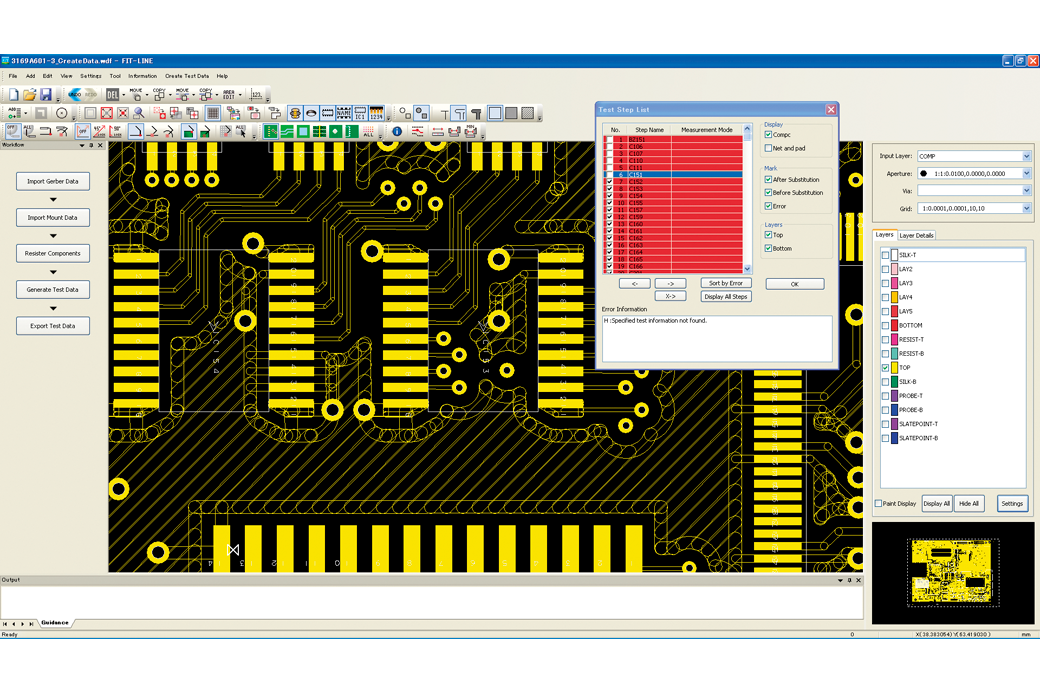

The UA1780 enables high-quality test programs in a short period of time by using net information that has been reverse-generated from Gerber data and component information libraries, and delivers maximum performance when used in conjunction with Hioki’s FA1240 Flying Probe Tester.

[Program,Test,Visualize] Populated Board Electrical Testing System

Hioki can prepare populated board testing system benchmarks if provided with the three types of data listed below.

[Program] FIT-LINE UA1780

[Test] FLYING PROBE TESTER FA1240

[Visualize] FAIL VISUALIZER UA1782

When testing populated boards, it's essential to create accurate data, measure boards accurately, and identify defective locations accurately.

Key Features

- No need for camera-based teaching

- No need to visually trace patterns under components

- Easy generation of high-quality test data without boards

- Support for the new FA1240 data format

Thanks to these features, programs can be created with plenty of time to spare before the prototyping stage. Anybody can generate high-quality test programs in a short period of time by using net information that has been reverse-generated from Gerber data and component information libraries. The UA1780 delivers maximum performance when used in conjunction with Hioki’s new FA1240-60 Flying Probe Tester.

Model No. (Order Code)

| UA1780 | Software and 4 years license |

|---|---|

| UA1780-01 | Software and 1 year license |

| UA1780-11 | 1 year license |

| UA1780-14 | 4 years license |

Making the most of your flying probe tester

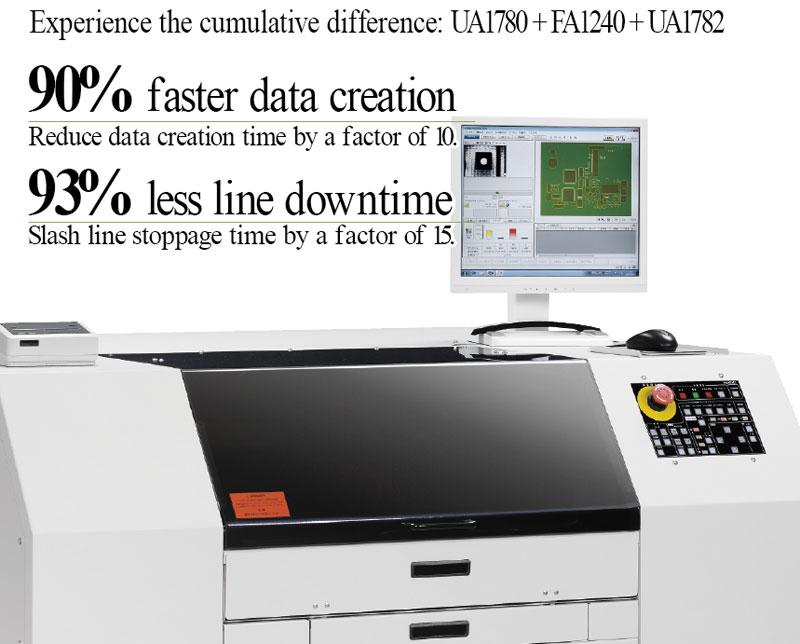

It's half true, and half untrue, to say that the ability to easily create data is distinct from the ability to easily test boards.

Being able to create data easily may have meant being able to test boards easily during the discrete era, but in creating the test data required by the FA1240, it is critical that creating accurate test data be a simple and easy-to-perform process.

By minimizing the difference between data that's good enough to operate the tester and data that's good enough to ship products, it is possible to minimize production line downtime (to allow for debugging and other modifications) and to ship products with peace of mind.

Specifications Overview

| Included | Installation CD, license key (USB), instruction manual (× 1 each) *Caution: Computer, monitor, and other hardware not included. |

|||||

|---|---|---|---|---|---|---|

| Gerber data input functions | Loading of Gerber files (RS-274X, RS-274D), aperture files, and drill files | |||||

| Mount data input functions | Loading of CSV files containing circuit names, layout coordinates, angles of rotation, shape names, and component names Support for operations such as rotation and mirroring, and display of data such as mounting locations |

|||||

| Graphic editing functions | Copying, movement, deletion, and other manipulation of figures | |||||

| Component library registration functions | Registration of component list displays and component size, height, and pin numbers; registration of test pin pairs, test modes, ratings (thresholds), and upper and lower limit values; duplication of libraries | |||||

| Test data generation functions | Reverse net generation, test point extraction taking into account components and patterns, automatic movement of test points underneath components, generation of open tests between adjacent pads, etc. | |||||

| Test point confirmation functions | Display of test points on a graphical screen | |||||

| Test data output functions | FA1240 files, 1240/1114 files | |||||

| Data management functions | Saving of databases and management of component libraries | |||||