Optimizing Switching Power Supply Selection Through Precise Current Measurement

Introduction

Energy efficiency and cost optimization are critical factors in modern equipment design. While power consumption is commonly measured using clamp-on power meters, the current capacity of switching power supplies often receives insufficient attention during equipment design. This oversight can lead to either performance issues or unnecessary costs. This application note explores how Hioki's data logging solutions can help precisely measure load currents to select the most appropriate switching power supply for your equipment.

The Challenge of Current Capacity Selection

Many manufacturers integrate commercially available switching power supplies into their production equipment—a practical and cost-effective approach compared to custom power supply development. While voltage requirements are straightforward to determine, selecting the right current capacity requires careful consideration:

• Too little capacity: Risks voltage fluctuations during load variations

• Too much capacity: Wastes standby power, increases physical size, and drives up costs

Finding the optimal balance requires accurate measurement of maximum current load under actual operating conditions.

Hioki's Solution for Precise Power Supply Selection

For equipment with multiple voltage power supplies, Hioki's LR8450 data logger combined with appropriate current sensors provides an ideal measurement solution. The LR8450 with a current module can simultaneously connect to five current sensors, available in both direct plug-in and wireless configurations for flexible deployment.

Key Benefits of Hioki's Measurement Solution

Compact, High-Precision Sensors for Confined Spaces

The CT7812 (2 A) and CT7822 (20 A) AC/DC current sensors utilize fluxgate technology for excellent temperature stability during extended recording periods. Their compact size-approximately the size of an index finger-makes them ideal for installation in crowded equipment enclosures.

Capture Rapid Current Fluctuations

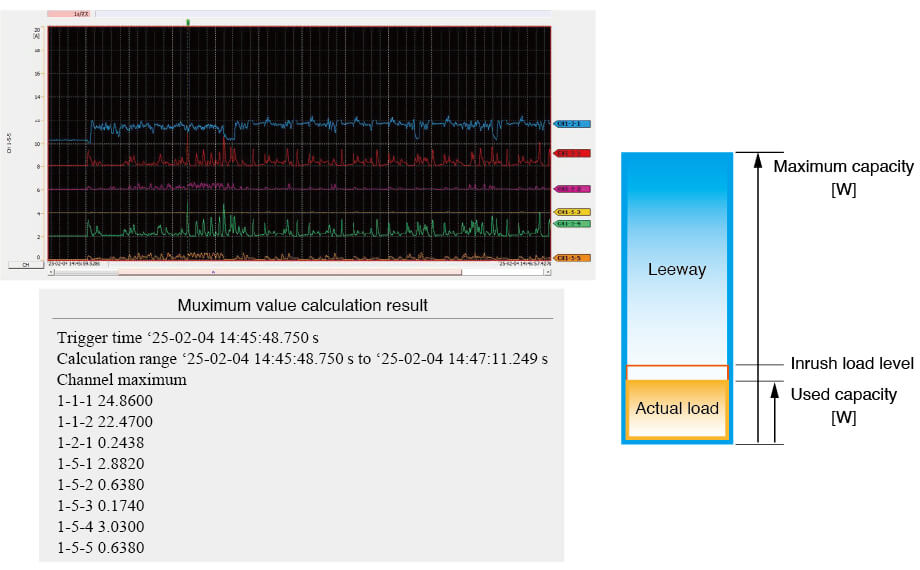

When paired with dedicated high-speed current modules (U8556 plug-in or LR8536 wireless), the LR8450 can record current changes with intervals as fast as 1 ms. Engineers can:

• Monitor load response in real-time on the main unit's screen

• Calculate maximum and average values from logged data

• Determine required current capacity based on comprehensive measurements

• Calculate power capacity through waveform analysis

Wireless Measurement for Comprehensive Equipment Evaluation

For large production or inspection equipment, the LR8450-01 wireless-compatible model enables simultaneous measurement of multiple points within a 30 m range:

• Connect up to five current sensors to each current module

• Link up to seven current modules to a single logger (35 total measurement points)

• Combine with voltage/temperature modules to simultaneously measure temperature or other physical quantities

• Create a comprehensive equipment evaluation system

Current Sensor Selection Guide

Hioki offers AC and DC current sensors of various current ratings. Sensors should be chosen based on the expected current magnitude and whether it is AC or DC. For example, the primary side of a switching power supply is AC and the secondary side is DC.

Data Loggers

• LR8450 MEMORY Hi LOGGER (for plug-in modules)

• LR8450-01 MEMORY Hi LOGGER (for plug-in and wireless model)

• U8556 Current Module (plug-in type)

• LR8536 Wireless Current Module

For Small to Medium Currents

• AC/DC Current Sensor CT7812: For circuits with load current ≤ 2 A

• AC/DC Current Sensor CT7822: For circuits with load current ≤ 20 A

For Large Currents

• AC/DC Auto-Zero Current Sensor CT7731: AC/DC 100 A

• AC/DC Auto-Zero Current Sensor CT7736: AC/DC 600 A

• AC/DC Auto-Zero Current Sensor CT7742: AC/DC 2000 A

Conclusion

Hioki's LR8450 series of data loggers and compact current sensors delivers the precision and flexibility needed to optimize switching power supply selection in production and testing equipment. This integrated solution provides real-time observation of synchronized data sources—including current consumption, voltage, temperature, strain, and CAN/CAN FD signals—all on a single main unit.

For detailed product information, please visit Hioki's website. Contact a HIOKI representative to request a demonstration or consultation regarding specific applications.