Safe Measurement of 1500 V DC in Photovoltaic System

Solving Maintenance Issues for High-Voltage Photovoltaic Systems

Momentum to reduce CO2 emissions in order to realize a decarbonized society is growing in the wake of broad adoption of power-generating equipment using natural energy such as solar power and wind power worldwide. Extremely large-scale installations like mega solar power plants and offshore wind farms are being built one after the next, and their capacity increases with each passing year. The voltage in photovoltaic systems is increasing to improve power generation efficiency. But photovoltaic systems that operate at higher voltages mean greater danger during construction and maintenance inspections.

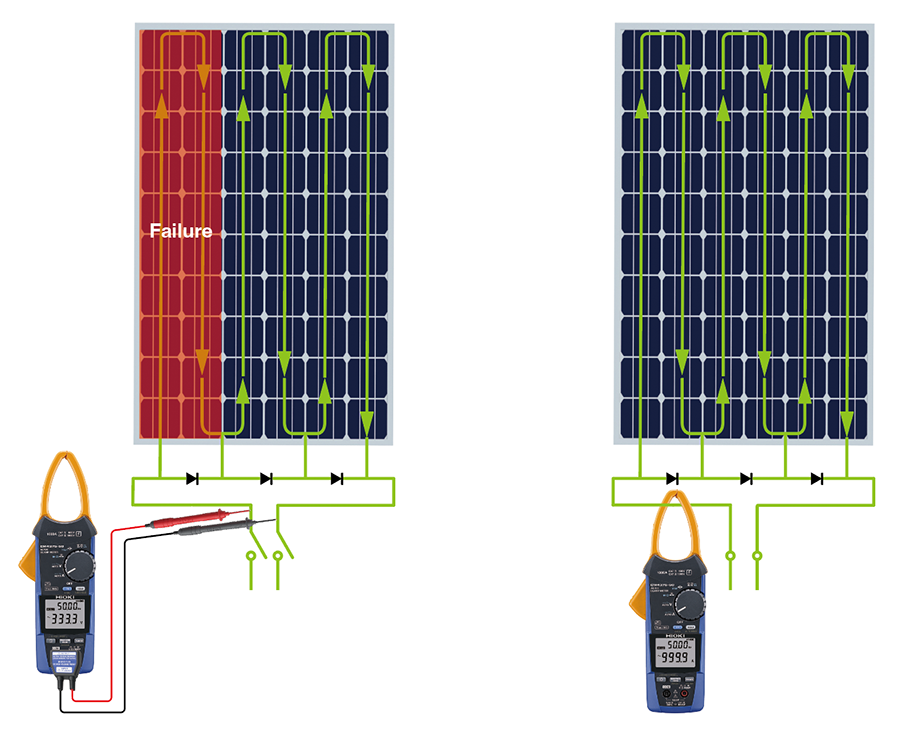

During maintenance inspections, various measuring instruments are used depending on the purpose to check whether there are any failures of solar panels. For example, the voltage measurement function of a digital multimeter or clamp meter is used to measure the open circuit voltage of a string. As a result, if the measured value is significantly lower than the design value, it can be determined that the string is broken or the module is defective.

Safety-related standards have been revised to take rising voltage into account, and measurement of grid-tied solar power equipment is now classified as measurement category III. The DC High Voltage Probe P2010, which supports CAT III 2000 V measurement, can be used with the AC/DC Clamp Meter CM4375-50 to resolve issues encountered during maintenance inspections and testing of increasingly high-voltage photovoltaic systems.

Safely measuring high-voltage photovoltaic systems

Issue 1: Insufficient voltage measurement scope

Company Z, owns and operates one of the largest scale solar power plants in the world. There was no need for 1500 V DC measurement in the past, but voltages have been increasing due to market availability of solar inverters that support 1500 V DC and increases in the number of connections for solar modules due to growth in the size of installations. As a result, the company had been using Hioki clamp meters with a voltage measurement scope of up to 1500 V. However, those models were used to measure installations that were not tied to the power grid. In addition, the clamp meters the company Z had been using did not have a large enough voltage measurement scope.

Voltages continued to rise, making it necessary to measure voltages in excess of 1500 V, for example, 1700 V. Systems are likely to continue to grow larger and more efficient in the future, necessitating instruments that can accommodate higher voltages.

Issue 2: Revisions to safety-related standards

The IEC 61010 international safety standard establishes measurement categories to ensure that instruments can be used safely while safeguarding people from electric shock and equipment from damage. Under IEC 61730-1, which defines photovoltaic (PV) module safety qualifications, PV modules are classified as overvoltage category III. Consequently, instruments used to measure such modules must support line-to-ground voltages equivalent to measurement category III. Demand for highly safe instruments that can withstand higher voltage inputs has risen

Issue 3: Poor inspection efficiency due to an extremely large number of measurement locations

During inspections of mega solar installations built on enormous tracts of land, inspection workers must inspect thousands of PV modules one at a time. The difficulty of carrying around large instruments adds to technician workload. Maintenance inspections of solar photovoltaic systems require instruments that are not only safe, but also compact, easy to carry, and efficient to use.

Resolution of issues with a CAT III 2000 V probe and clamp meter

Company Z, which was seeking the ability to measure voltages of 1500 V DC and greater with a safer instrument, decided to deploy the Hioki DC High Voltage Probe P2010 and AC/DC Clamp Meter CM4375-50. The reason is because the P2010 has CAT III 2000 V measurement capability, and the CM4375-50 of its portability, convenience, and efficiency.

The DC High Voltage Probe P2010 is a CAT III 2000 V probe that delivers both compact size and safety as a result of Hioki’s proprietary expertise. By attenuating and outputting the measured voltage, the instrument can be used to measure up to 2000 V DC when combined with a clamp meter or digital multimeter.

The P2010 is small and light enough to be held in one hand, addressing two issues of past models: (1) cumbersome instrument size, reflecting the need to provide sufficient insulation performance to protect against electric shock, and (2) inconvenience due to poor portability in the field. Thanks to a safe design that can withstand 2000 V DC, the probe prevents electric shock and equipment damage. Moreover, the P2010’s long-tipped probes boost work efficiency since they’re easy to place in contact with metal terminals located deep inside junction boxes.

The AC/DC Clamp Meter CM4375-50 is a clamp meter with slim jaws designed to be safely applied around thin cables in intricate locations. The instrument automatically determines whether the current being measured is DC or AC, and it supports currents of up to 1000 A, AC voltages of up to 1000 V, and, when used with the P2010, DC voltages of up to CAT III 2000 V.

The CM4375-50’s DC HIGH V PROBE mode converts and displays DC voltages based on the P2010’s output ratio, eliminating the need to convert displayed values. During maintenance inspections of solar photovoltaic systems, this single instrument can be used to check each string’s open-circuit Voltage (Voc) and operating current.

Open-circuit Voltage (Voc), Operating current

Open-circuit Voltage (Voc), Operating current

During inspection work on mega solar installations occupying large tracts of land, the instrument is small and light enough to hold in one hand, and it can be easily carried, even when used with the P2010. Its compact, lightweight construction eases the inspection workload.

Hioki instruments that accommodate the evolution of energy systems

The voltages at which photovoltaic systems operate will likely continue to rise in the future. Such increases are an inevitable part of increasing the efficiency of generating and storage equipment–not only solar photovoltaic systems, but also power storage systems used in connection with large-scale wind power installations and hybrid generation plants that combine thermal and natural energy components.

Hioki offers a full array of instruments for use in maintenance inspections, including power quality analyzers, insulation testers, and digital multimeters.

We will continue to evolve the functionality of these offerings, for example to increase voltages and improve measurement efficiency, as photovoltaic systems evolve. We will also enable measurement tasks that seemed impossible in the past by assessing market trends and seeking feedback from personnel involved in maintenance inspection, manufacturing, and development work.

Hioki offers a broad range of measuring instruments with functionality engineered to meet customers’ demands, and demonstration instruments are available. Please contact your authorized Hioki distributor or reseller if you wish to experience the functionality of our products for yourself. We’re also happy to provide samples so that prospective customers can conduct measurement tests. And please get in touch with any measurement issues you’d like to resolve or instruments in which you're interested.