Motor Weld Quality Testing

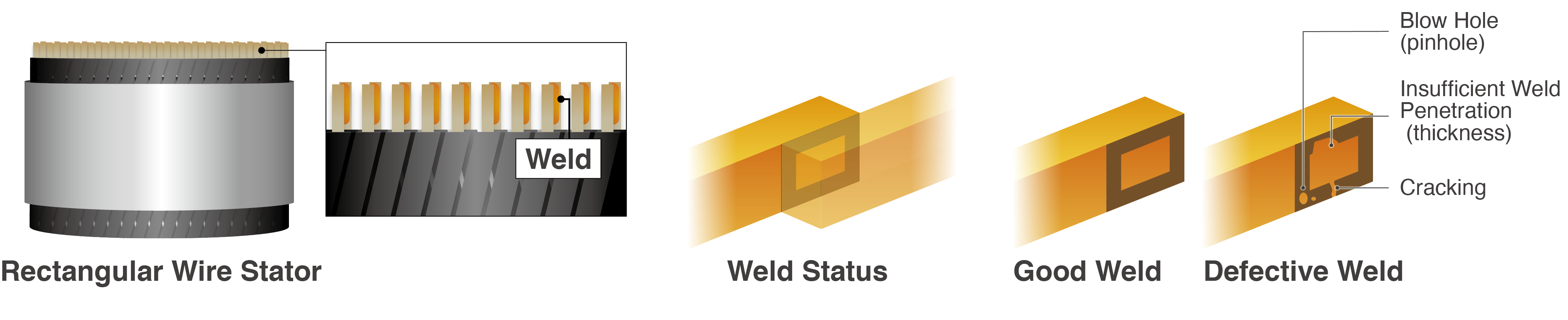

Test weld quality (check for weld defects) in rectangular wire stators using a DC resistance meter with high resolution and measurement accuracy.

Measurement Example

Rectangular Wire Stators

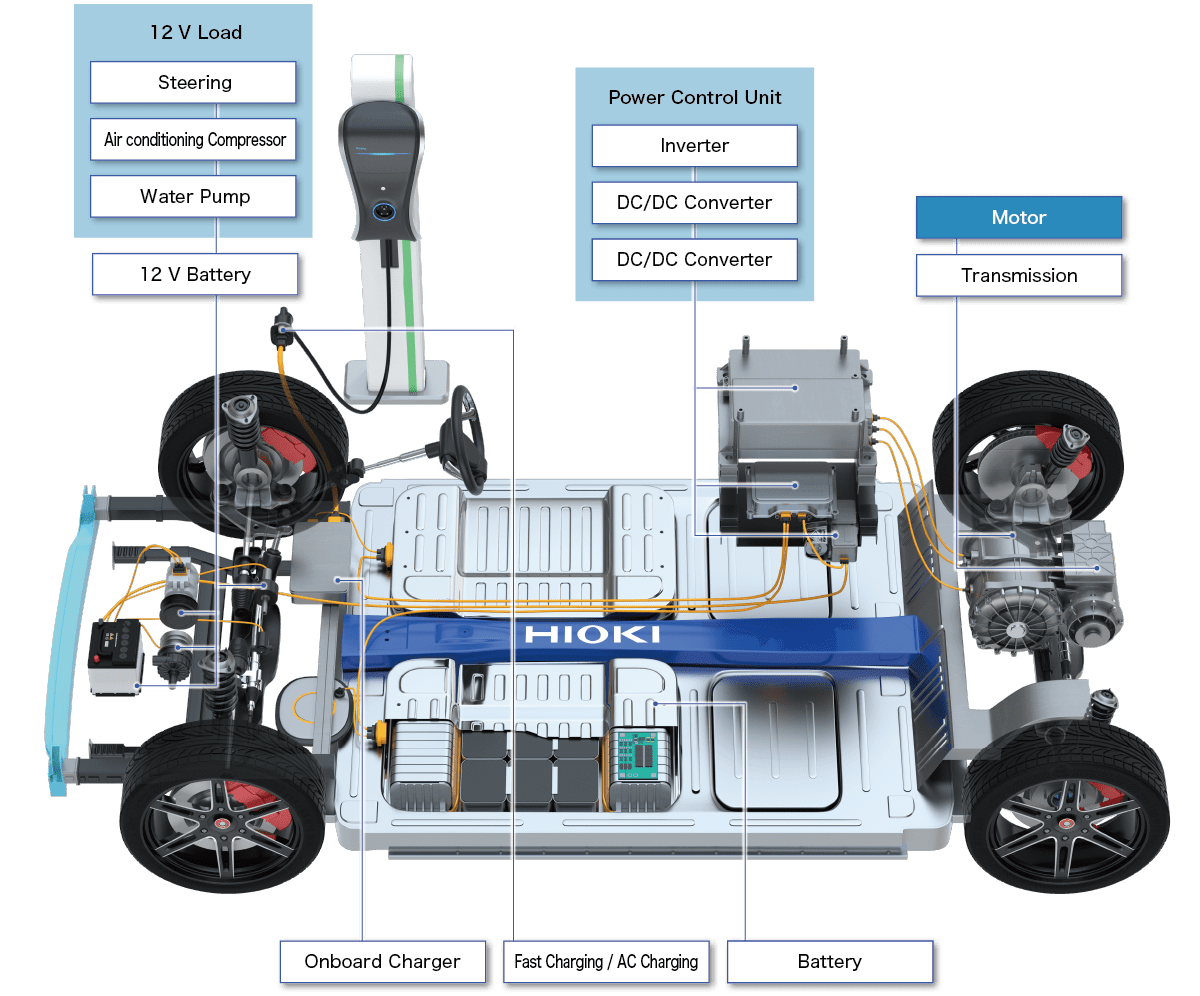

Rectangular copper wire that has been bent is affixed to the stator core, and rectangular wires from the same phase are welded together by a robot. Incomplete bonds can lead to latent defects due to insufficient weld penetration, cracking, and pinhole formation.

Testing Weld Quality with DC Resistance Measurement

Probes for detecting voltage contact both side of welding point. The RM3545A can measure resistance of welding.

You can easily built measurement system by using the Z3003 multiplexer unit with the RM3545A-2.

Since the Resistance Meter RM3545A can measure resistance at a resolution of 1 nΩ in the 1000 μΩ range, the weld state can be judged on the basis of DC resistance values.

*Use the Temperature Sensor Z2001 with the RM3545A’s temperature correction function.

Instruments Used

RESISTANCE METERRM3545A-2

World-class Accuracy and Digit Count

Accurate Measurement of Super-low Resistance Values Allows quantification of the status of rectangular wire welds, playing a positive role when testing in the field.

Learn More Download Brochure

・Measurement basic accuracy of 0.006%

・Display count of 6 digits

Accurate Measurement of Super-low Resistance Values Allows quantification of the status of rectangular wire welds, playing a positive role when testing in the field.

Learn More Download Brochure