Winding Resistance Measurement

Check for wire breaks by measuring winding resistance with a high level of precision.

Check for incorrect wire thickness and turn count by using a high-precision resistance meter to make the measurements.

Check for incorrect wire thickness and turn count by using a high-precision resistance meter to make the measurements.

Measurement Example

Testing Winding Quality with Resistance Measurement

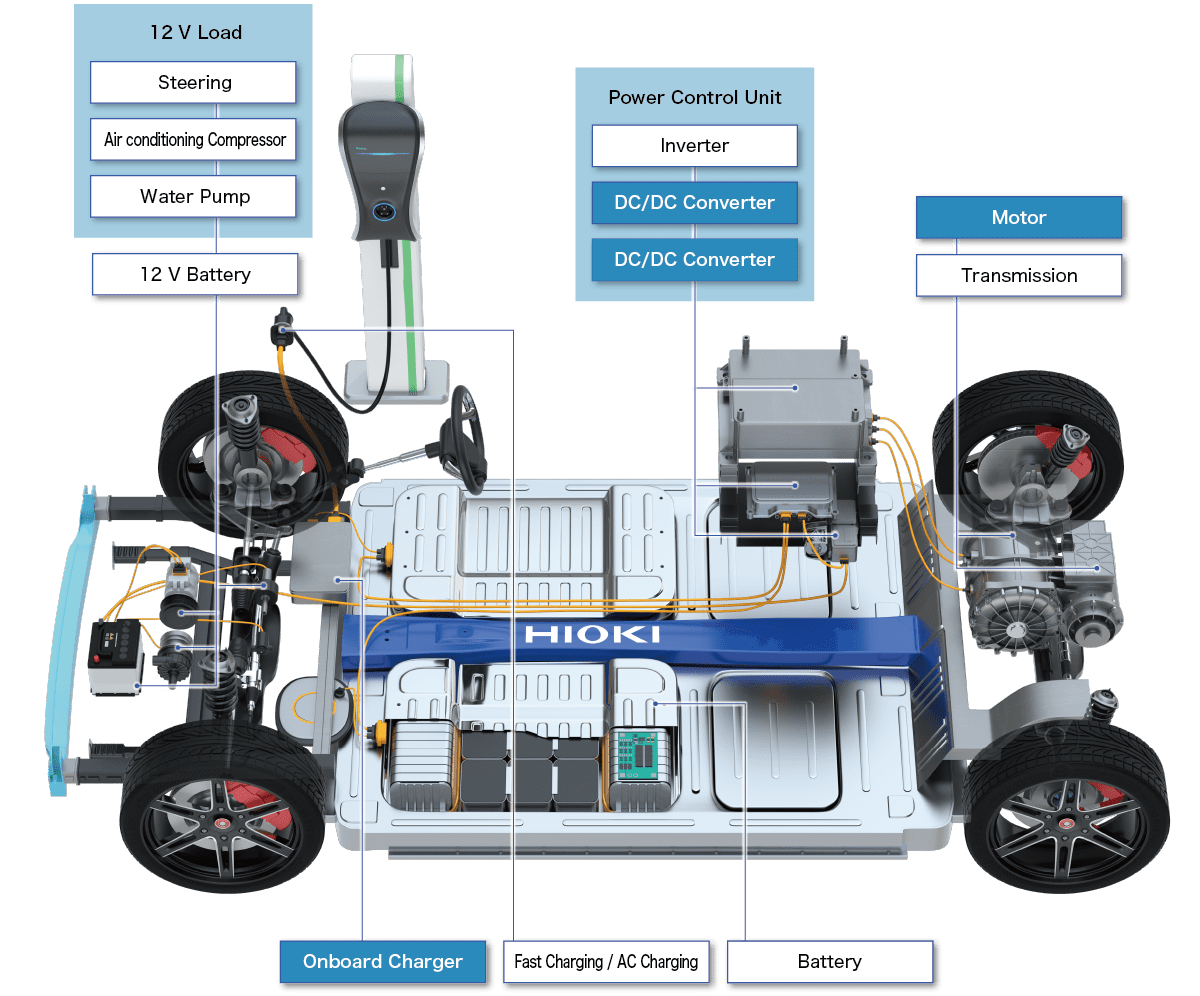

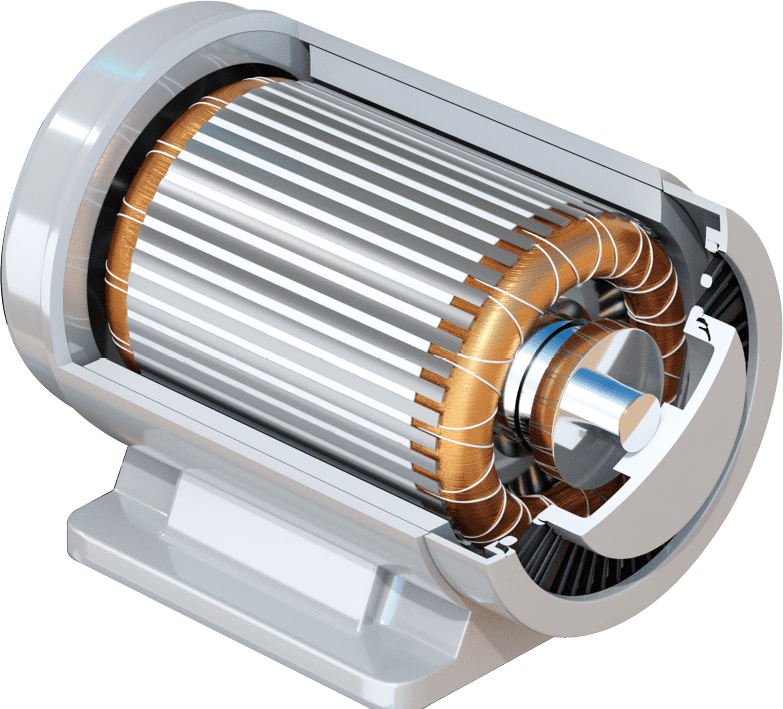

To operate a motor efficiently, it's necessary to apply a large current.

To accommodate such currents, thick windings with low resistance are essential.

To accommodate such currents, thick windings with low resistance are essential.

What can resistance values tell us?

- Incorrect Wire Thickness

- Incorrect Number of Turns

- Winding Shorts

Motor Windings

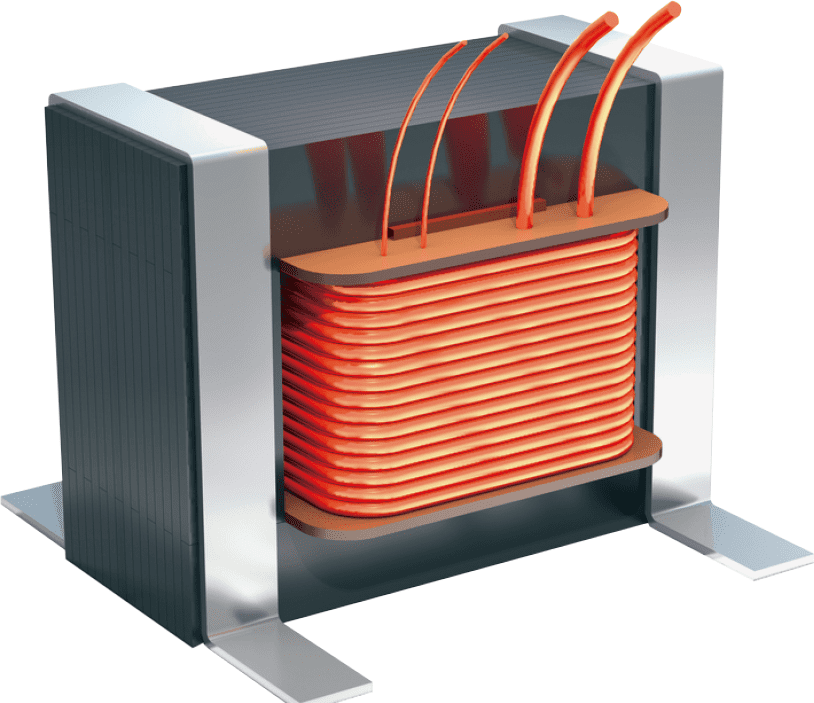

Transformer Winding

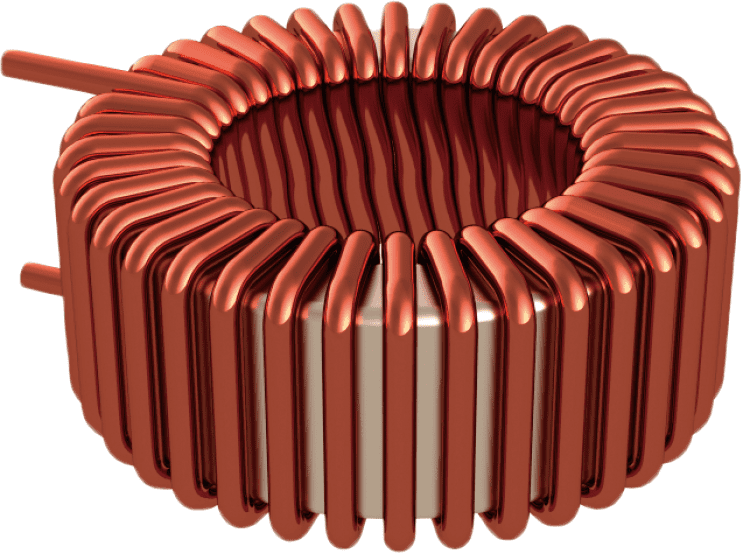

Coil Winding

Performance Required for Resistance Measurement

Winding resistance, which is continually falling as technology progresses, can be accurately measured using a resistance meter.

Required Performance

- Low-Resistance Measurement When measuring large windings, where low resistance values are increasingly becoming the norm, values must be managed on the order of 10 μΩ.

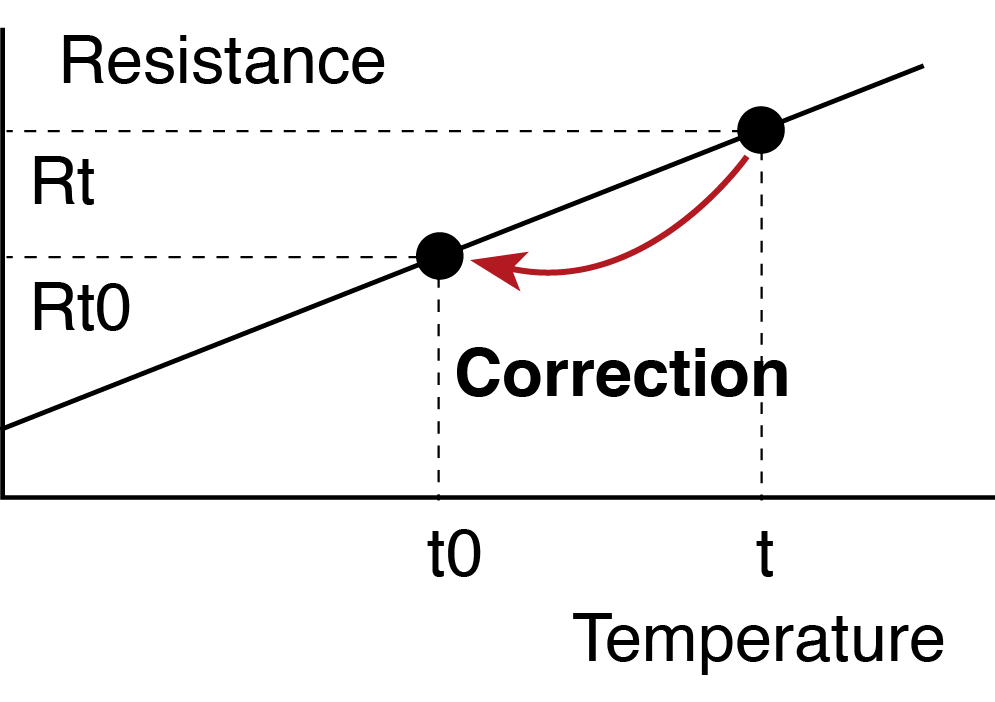

- Ambient Temperature Correction It's essential to perform temperature correction since wire resistance values vary with temperature.

Instruments Used

RESISTANCE METERRM3545A

・High-precision resistance meter with a resolution of 0.001 μΩ

・The RM3545A-2 features an available internal multiplexer that efficiently measures resistance at multiple points.

Learn More Download Brochure

MULTIPLEXER UNITZ3003

RESISTANCE METERRM3548

・Temperature correction functionality and interval measurement are convenient in temperature rise testing of motors and transformers.

・The portable form factor is ideal for measuring large motors and transformers.

Learn More Download Brochure