Motor Measurement

From Performance Analysis to Quality Testing

Improving Motor Performance and Quality High-Precision Measurement Solutions

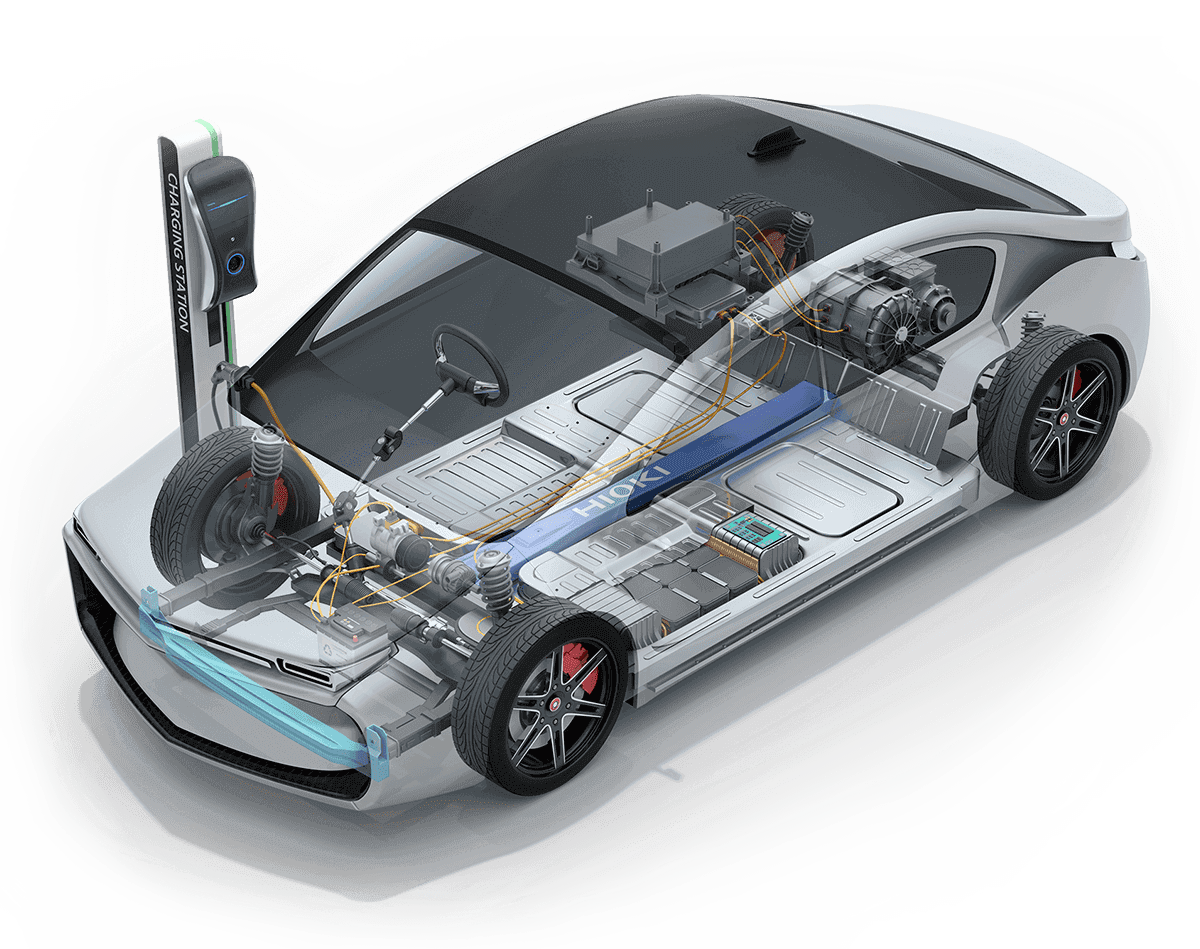

Hioki offers a diverse array of motor measurement solutions that can be used in applications ranging from performance analysis to quality testing.

The ability to assess and analyze using high-precision measurement technologies provides valuable assistance to engineers as they work to increase motor performance and quality.

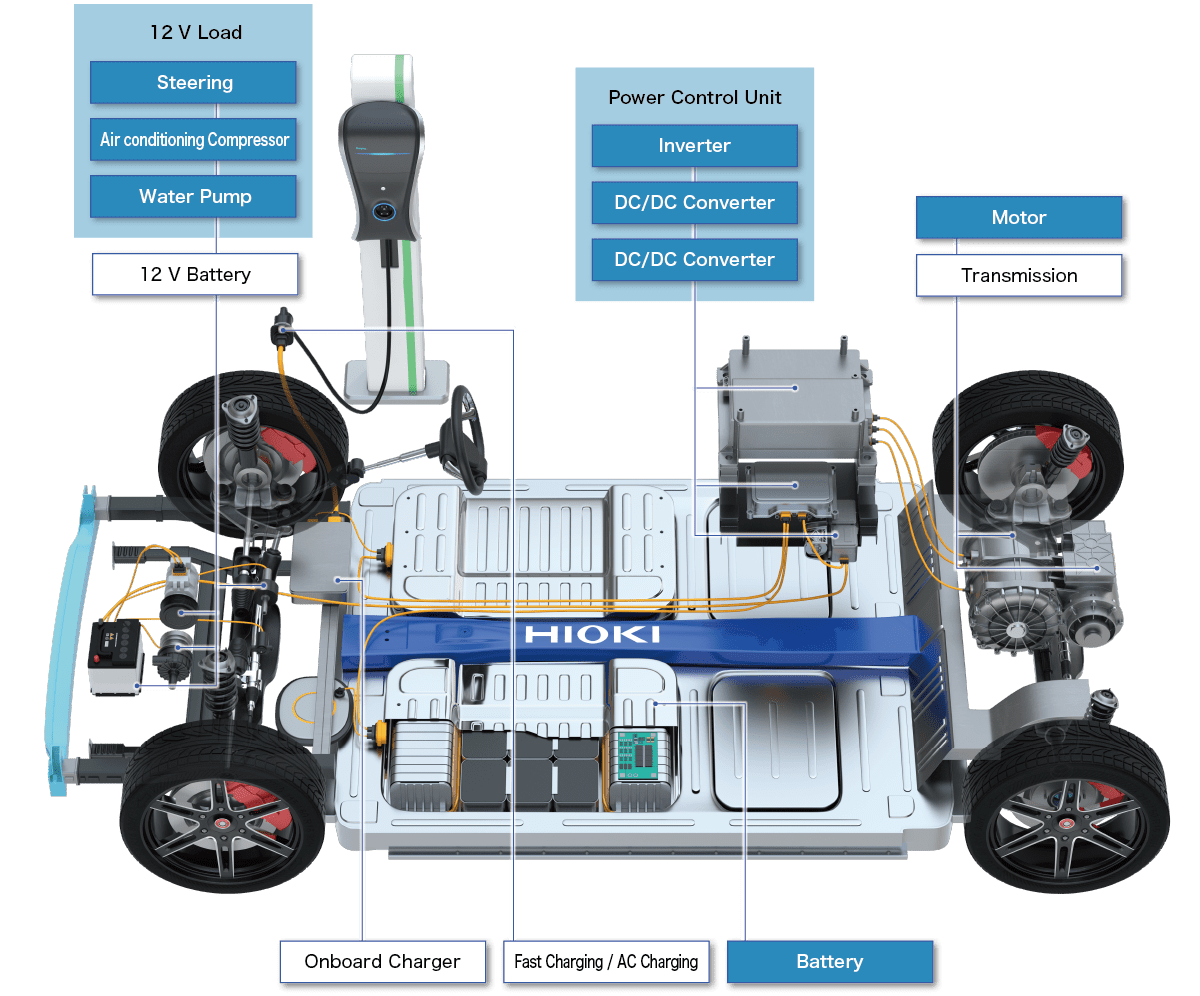

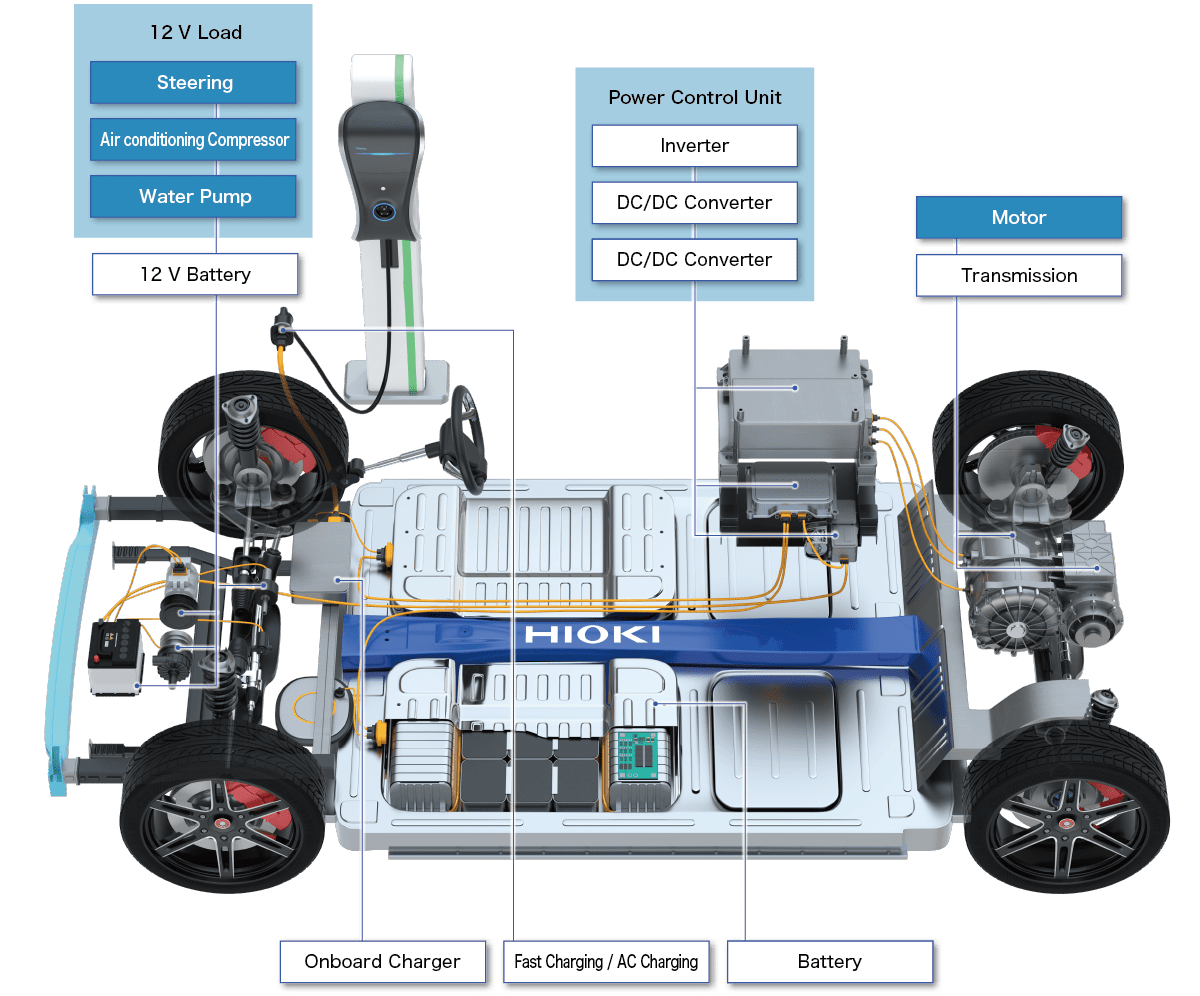

Evaluating Inverter Motor Efficiency and Loss

Simultaneously measure inverter input and output power, and motor output.

Evaluate inverter, motor, and overall system efficiency and loss in an accurate and highly reproducible manner.

Evaluate inverter, motor, and overall system efficiency and loss in an accurate and highly reproducible manner.

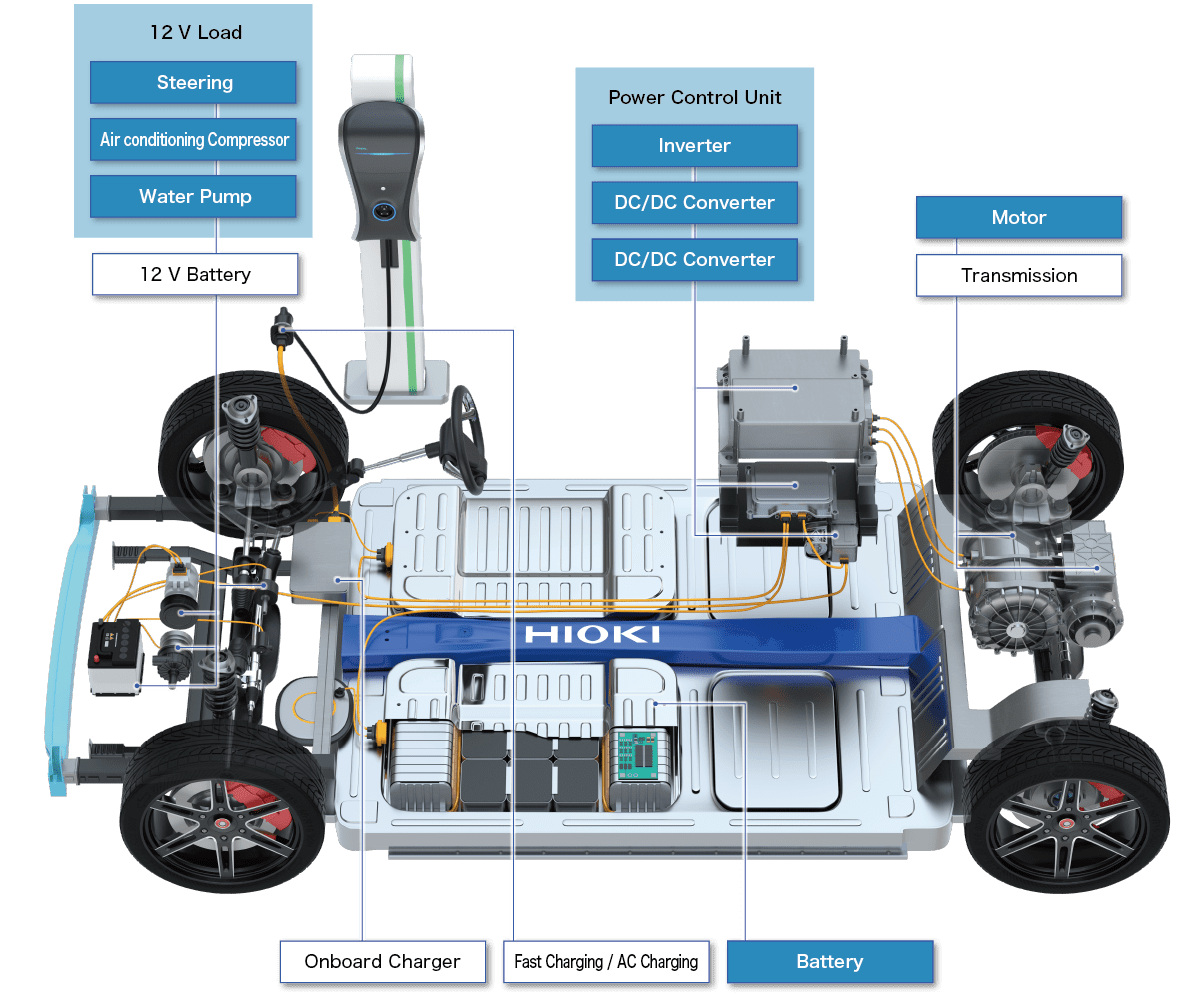

Inverter motor ECU measurement and compliance testing

Make quick work of PCU compliance testing by taking advantage of PW6001 and INCA link functionality so that you can use the PW6001 to perform accurate power and motive power measurement. You can simultaneously monitor CAN bus data and ECU RAM values.

Identifying PMSM Motor Parameters

Identify more accurate motor control motor control by using motor parameters measured under actual operating conditions in upstream design processes.

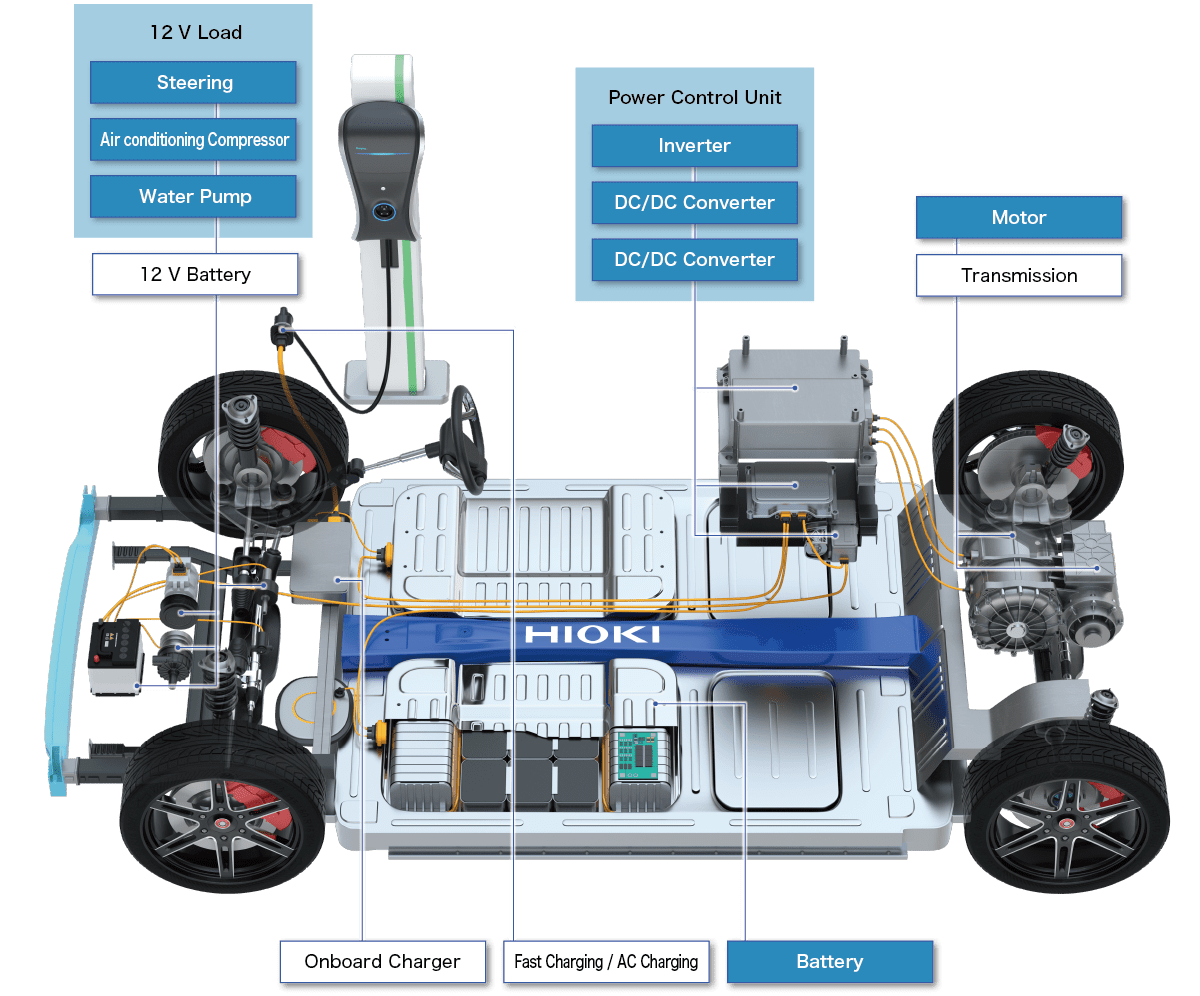

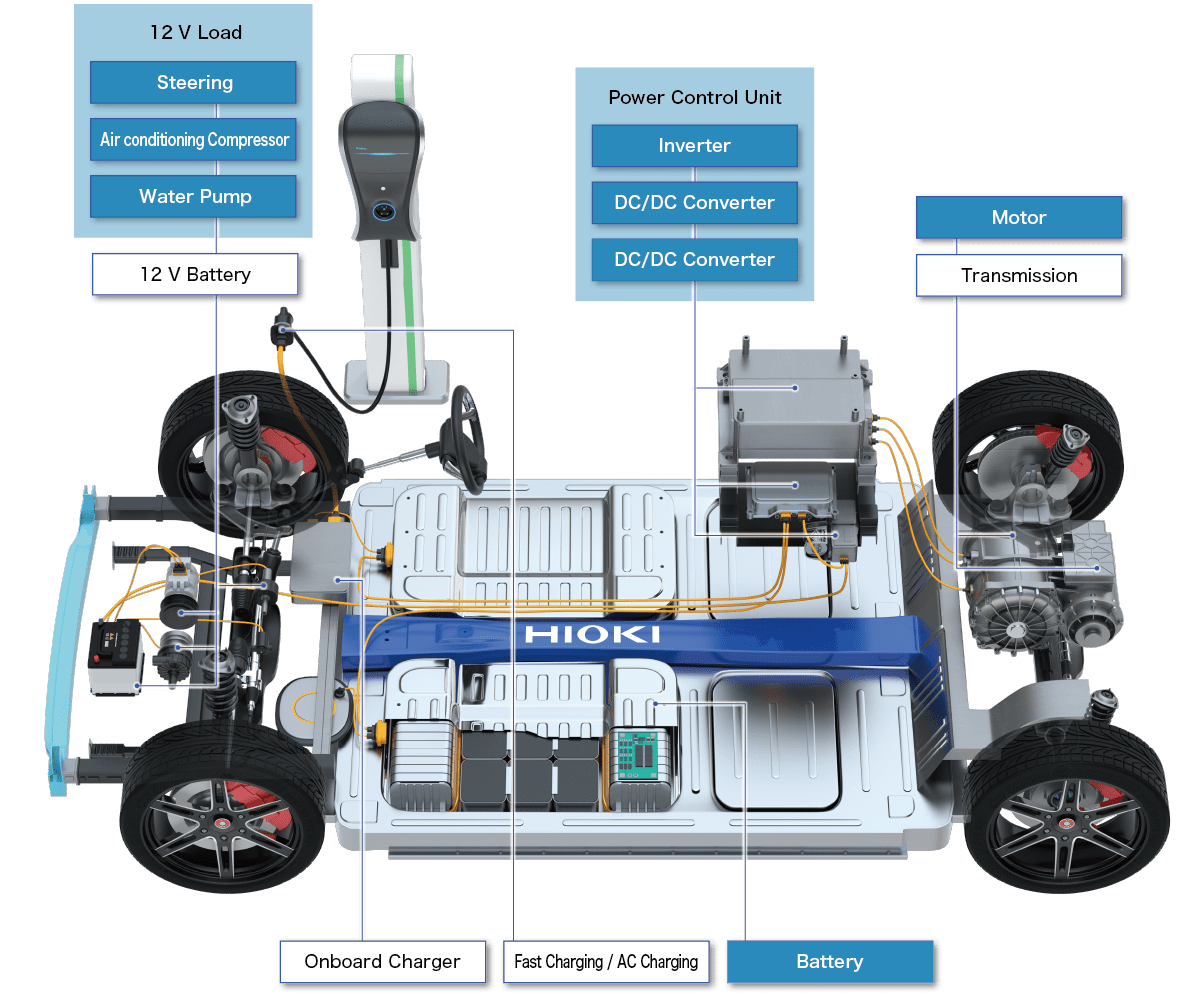

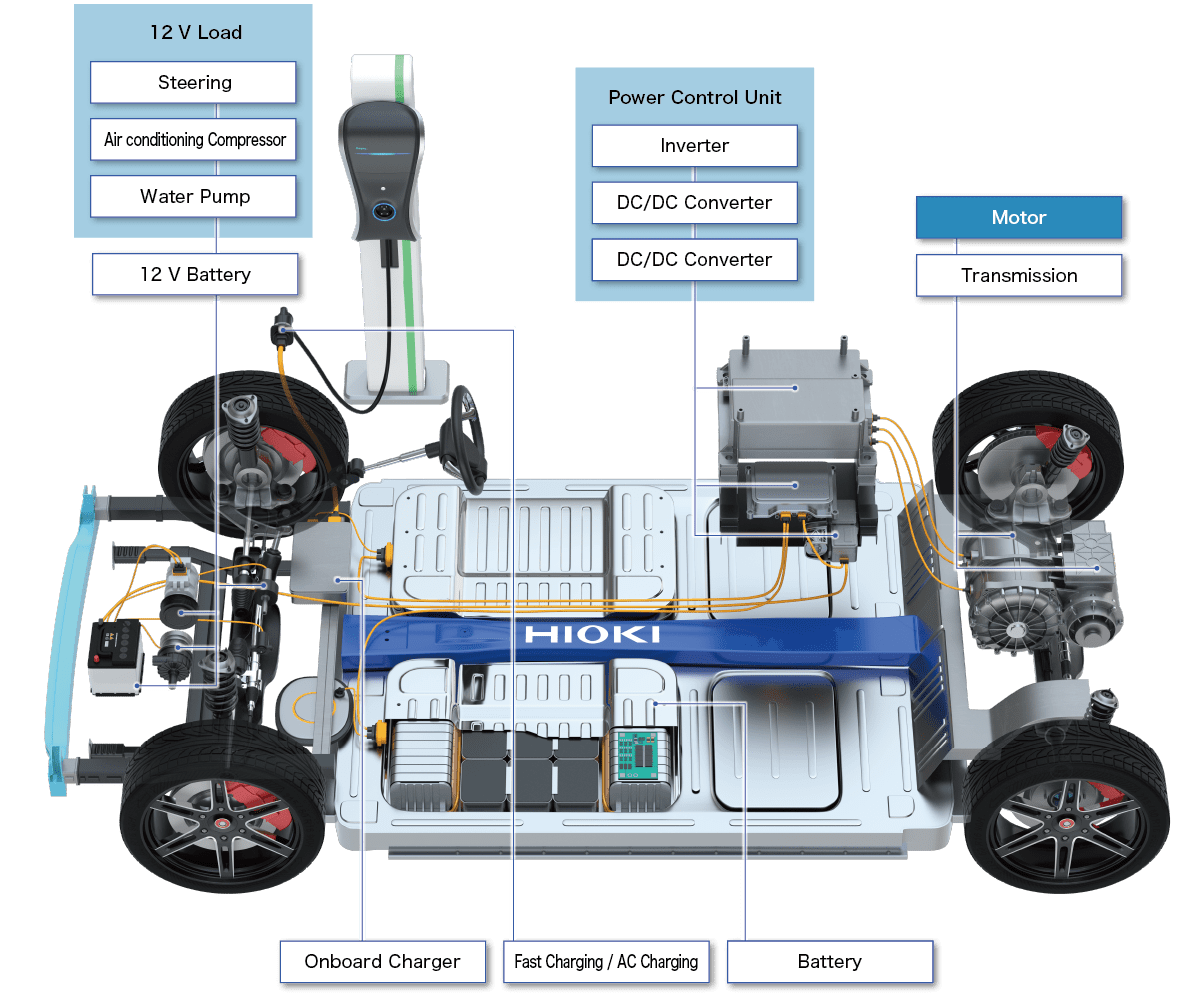

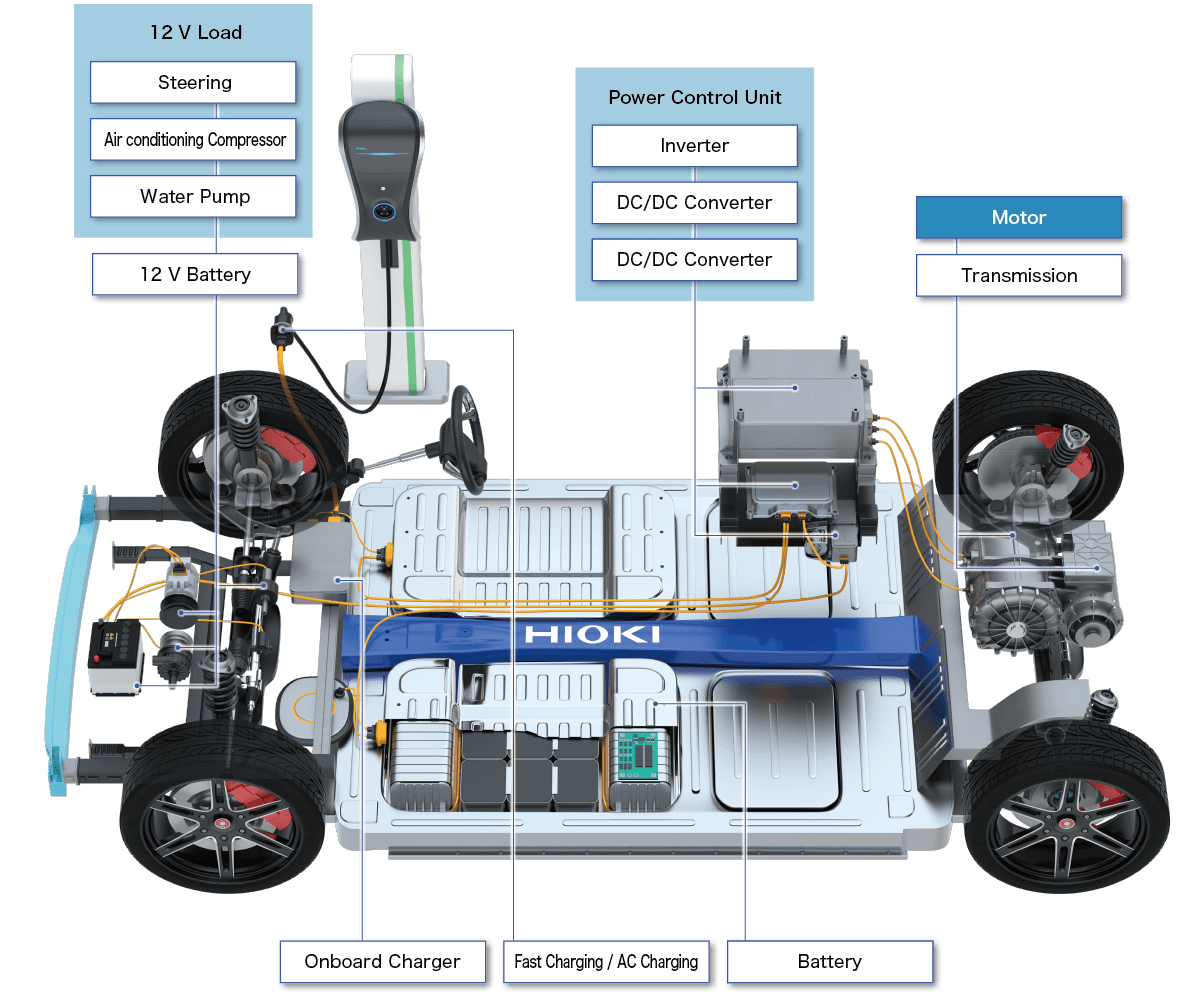

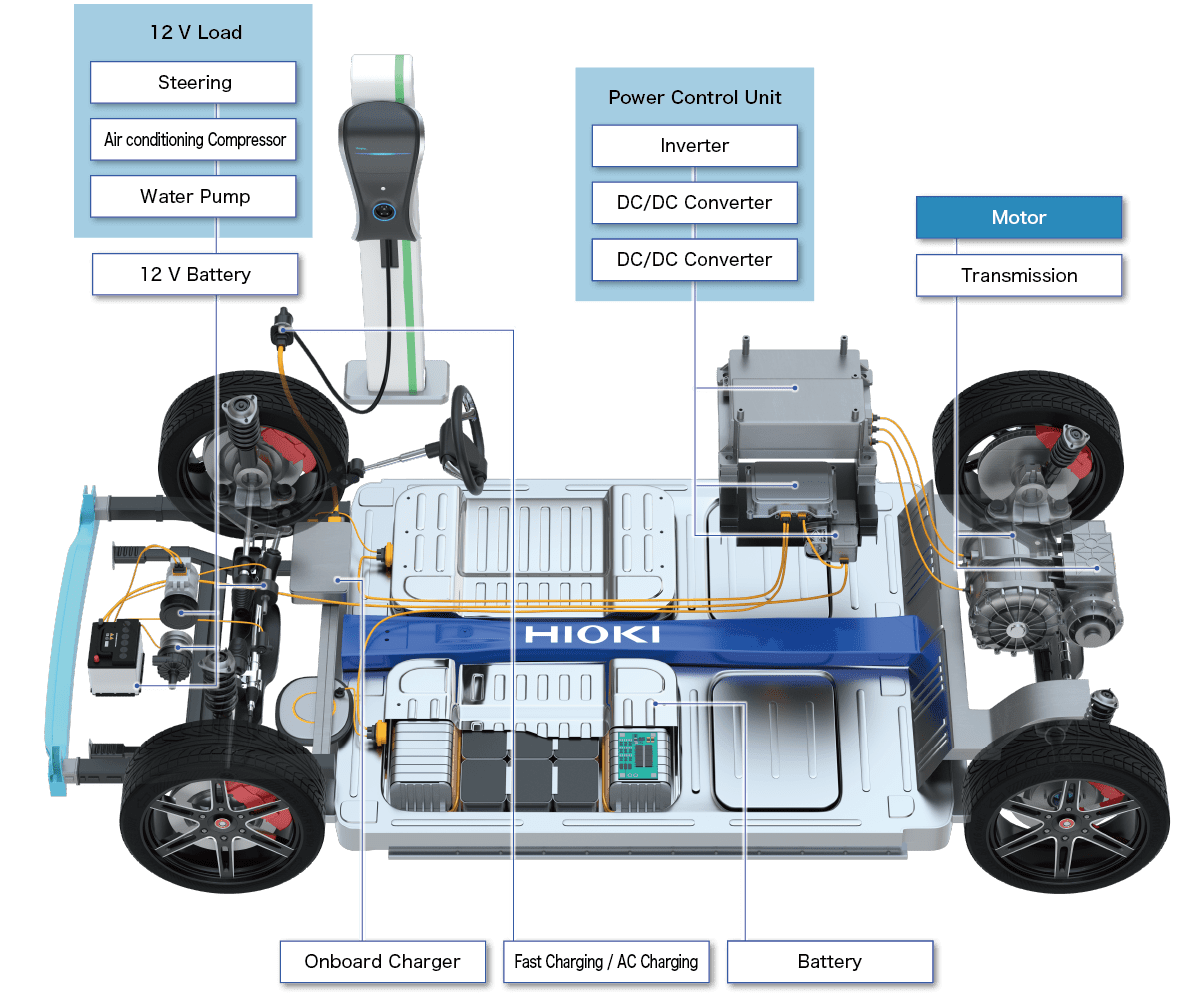

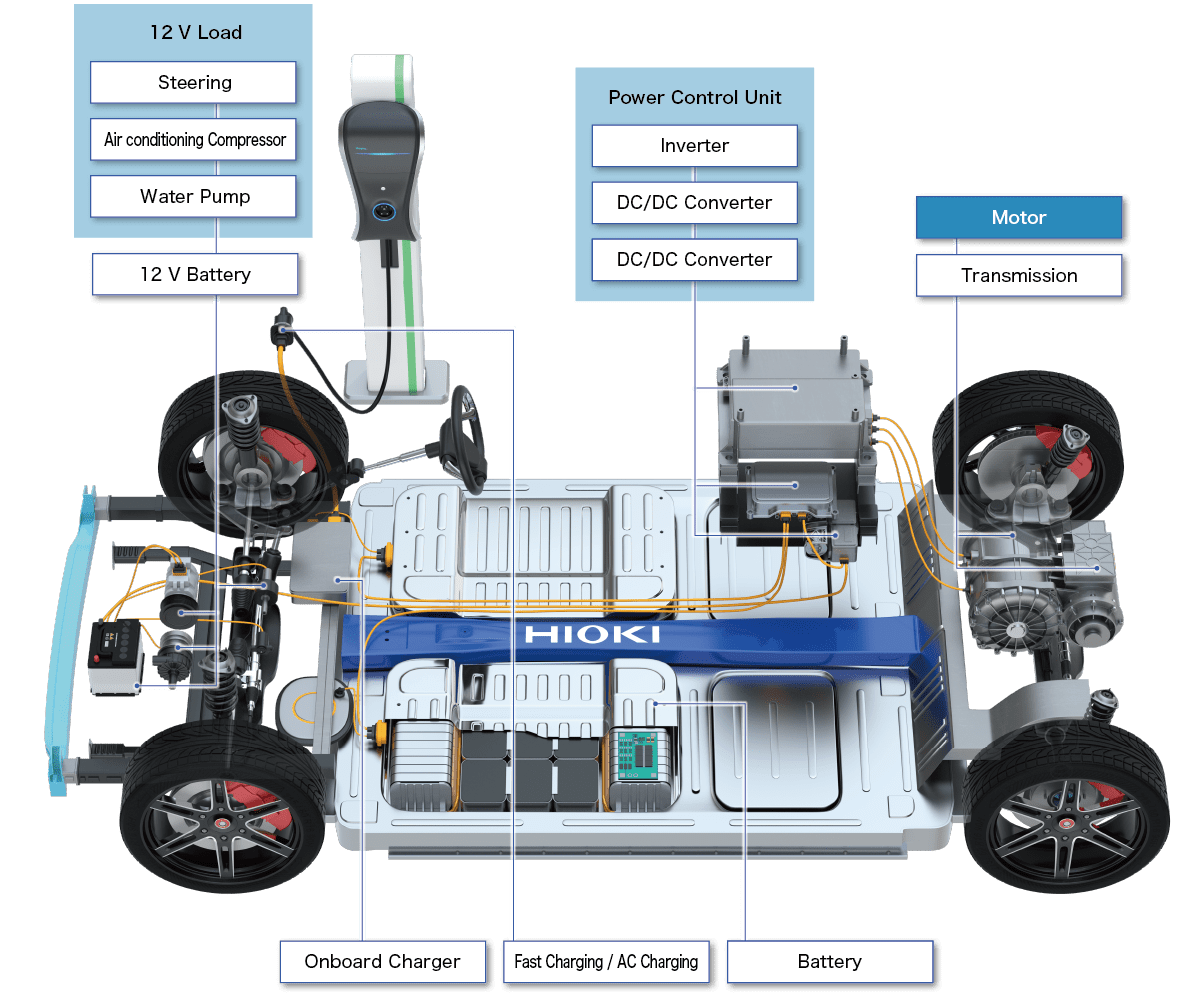

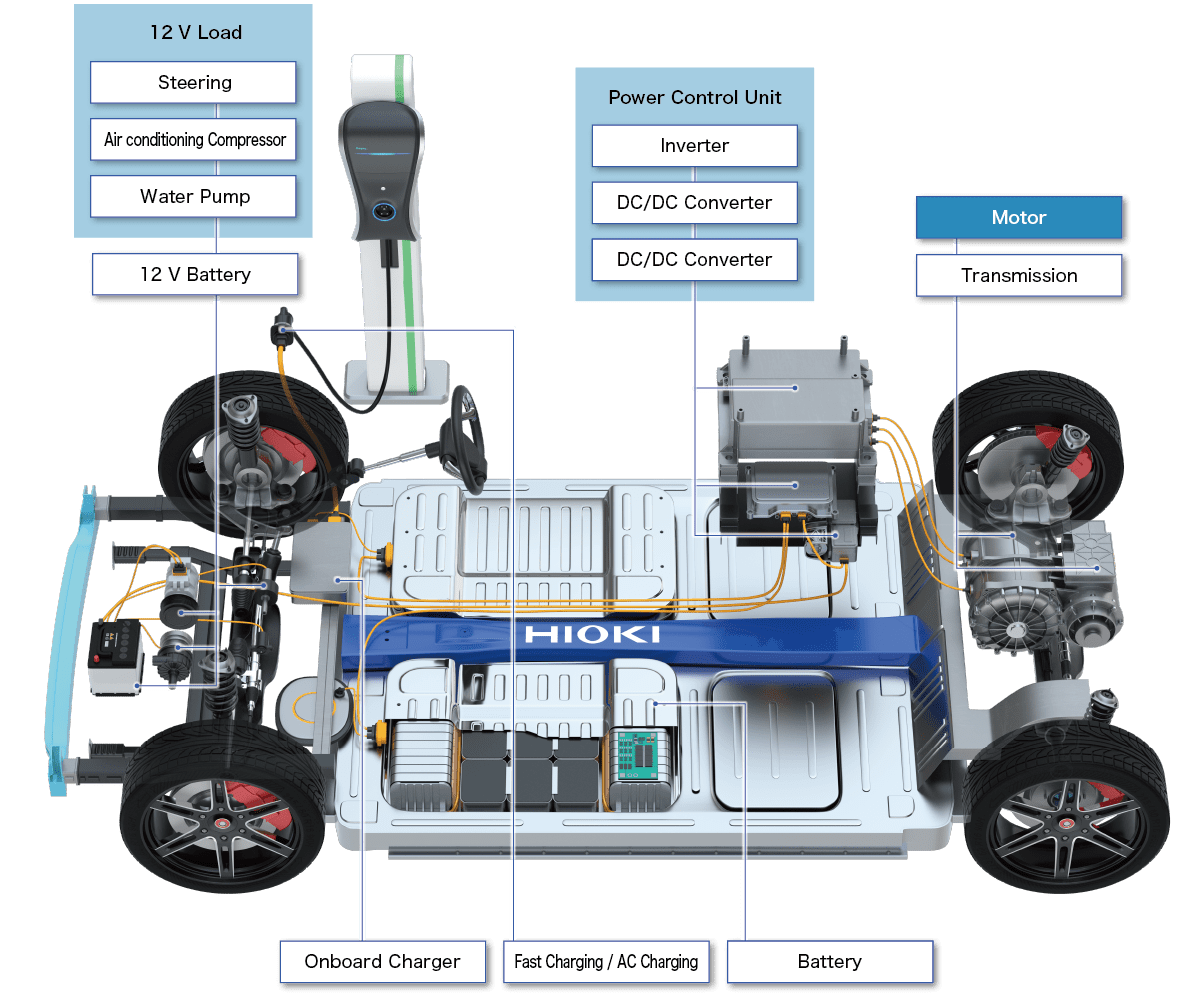

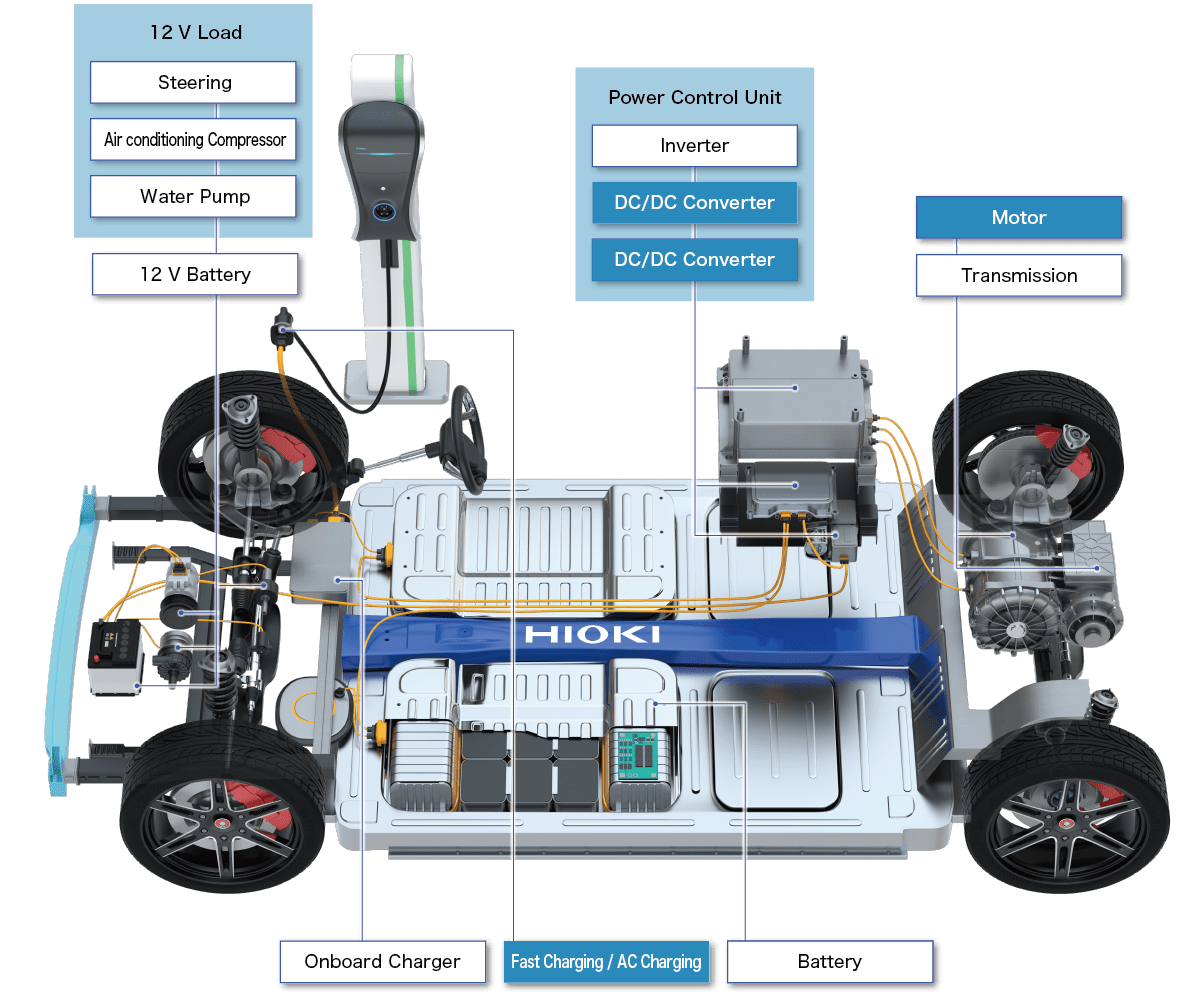

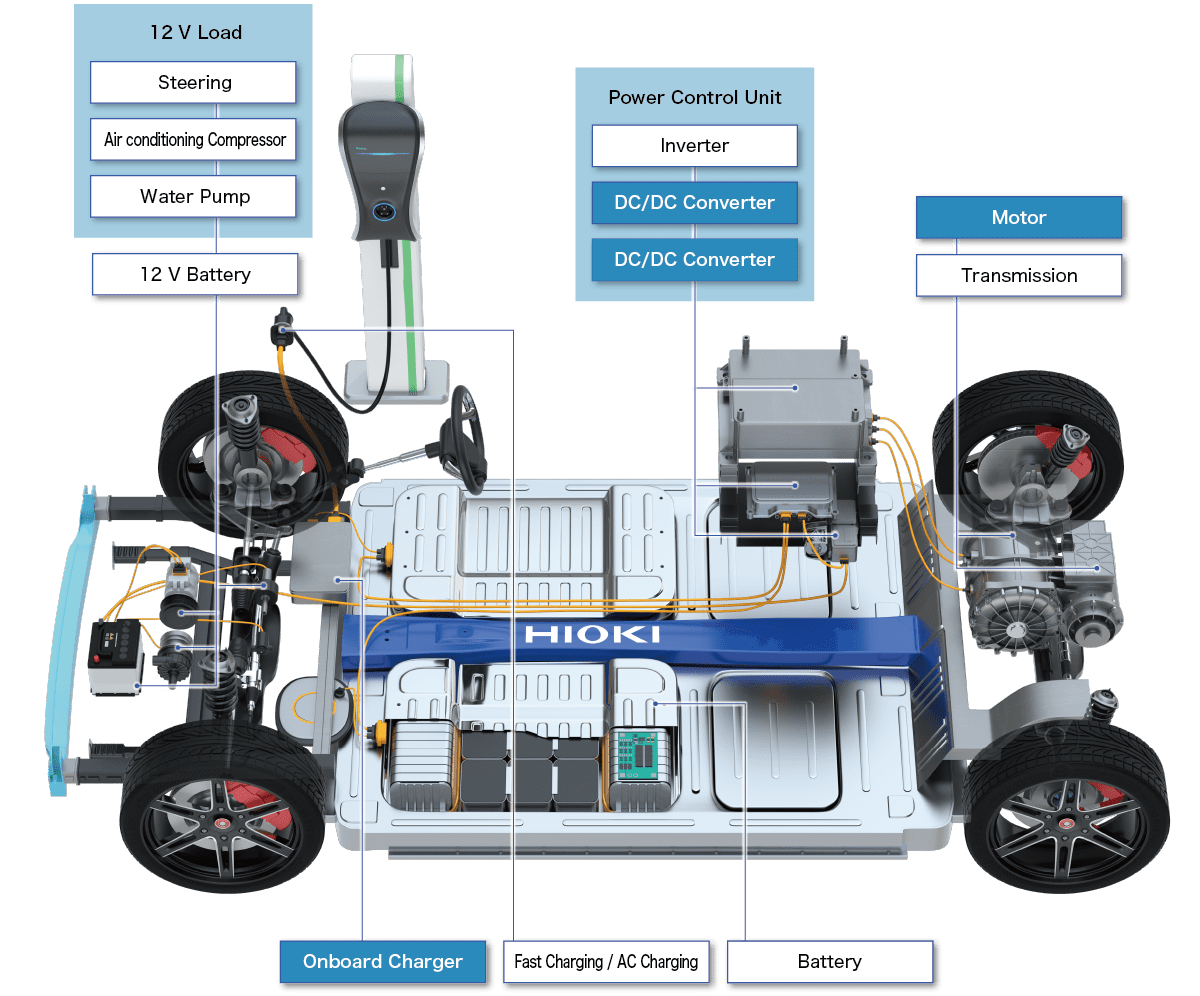

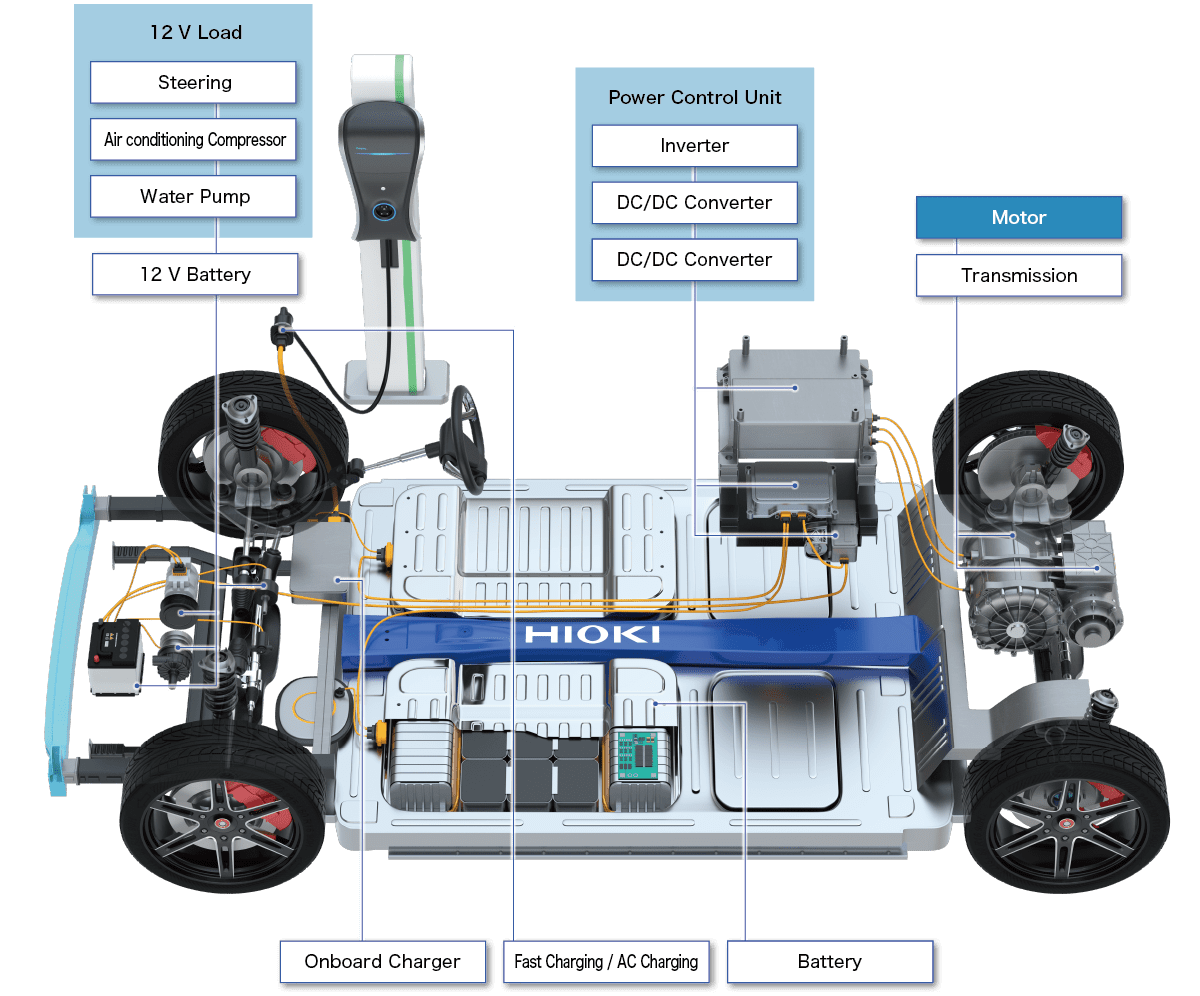

Test Automobile Fuel Economy

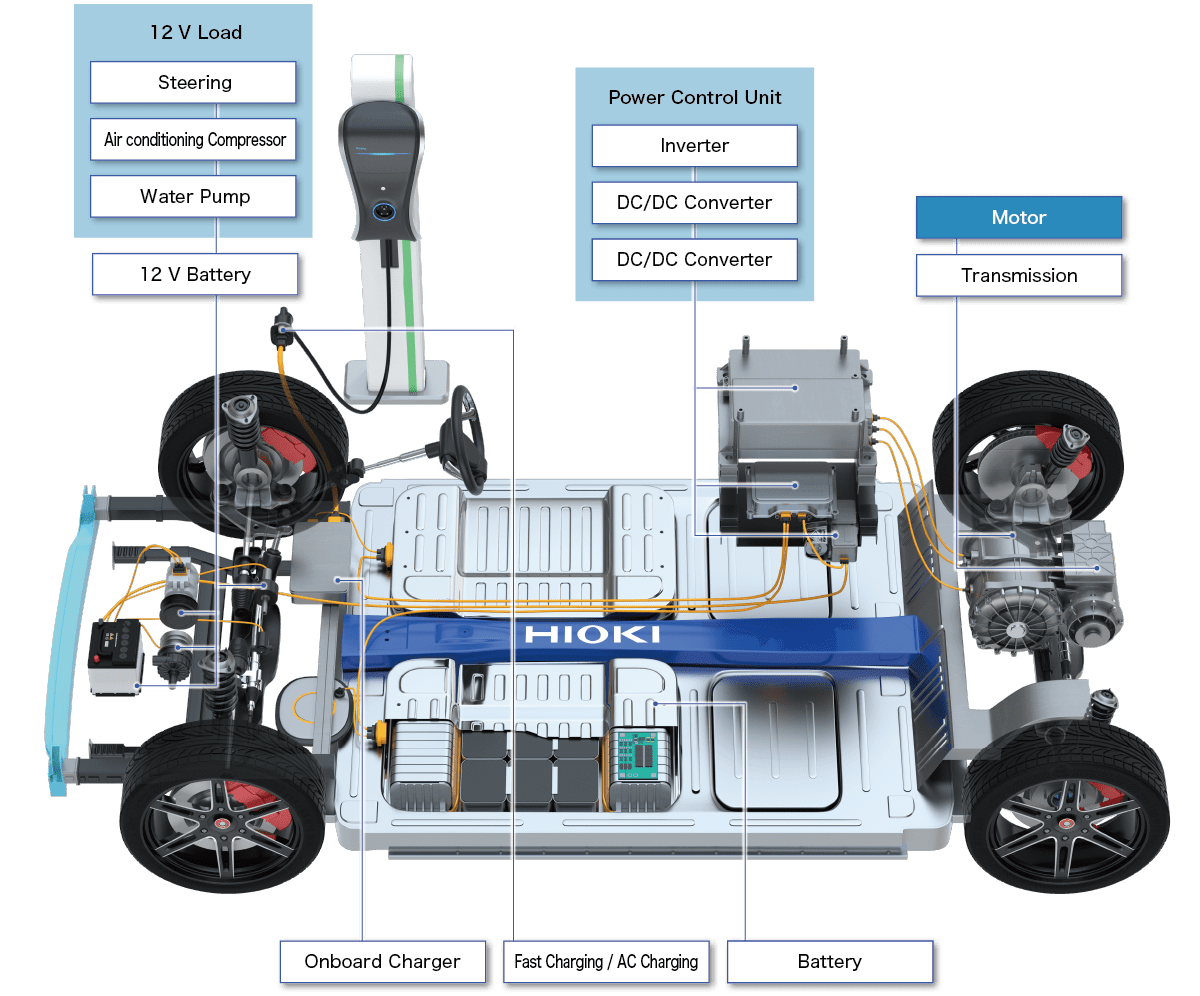

Taking fuel economy measurements that comply with WLTP international standards requires the precise measurement of current integration and power integration for the recharging/discharging of each battery in the system.

High accuracy clamp current sensors, the excellent DC accuracy of the PW3390, and the ability to integrate current and power at 50 ms intervals are extremely effective in meeting this application.

High accuracy clamp current sensors, the excellent DC accuracy of the PW3390, and the ability to integrate current and power at 50 ms intervals are extremely effective in meeting this application.

Measuring Motor Temperature

Apply thermocouples to the motor frame and winding to record temperature variations.

Display and record differences in temperature relative to the measurement environment as a waveform in real time.

Display and record differences in temperature relative to the measurement environment as a waveform in real time.

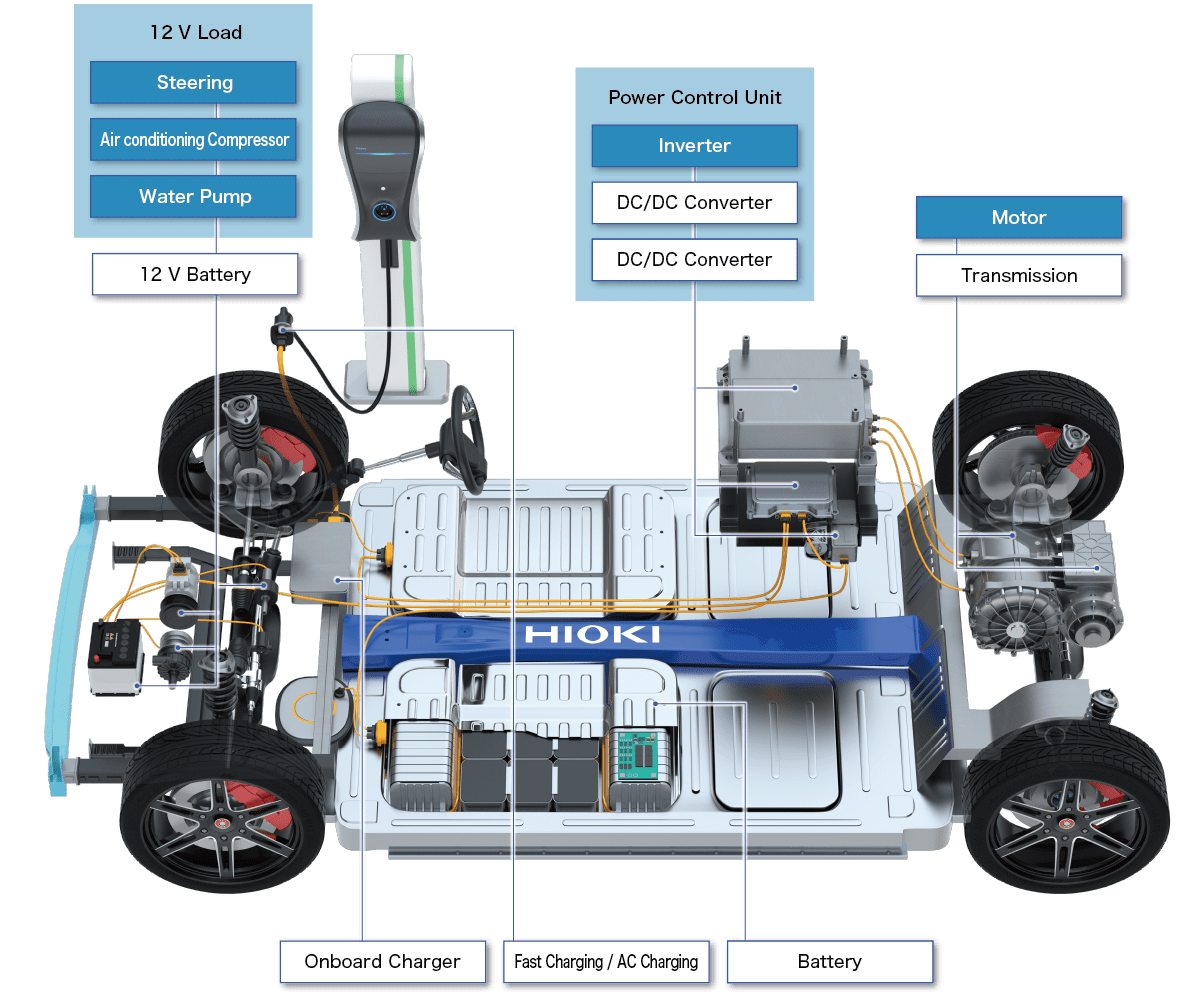

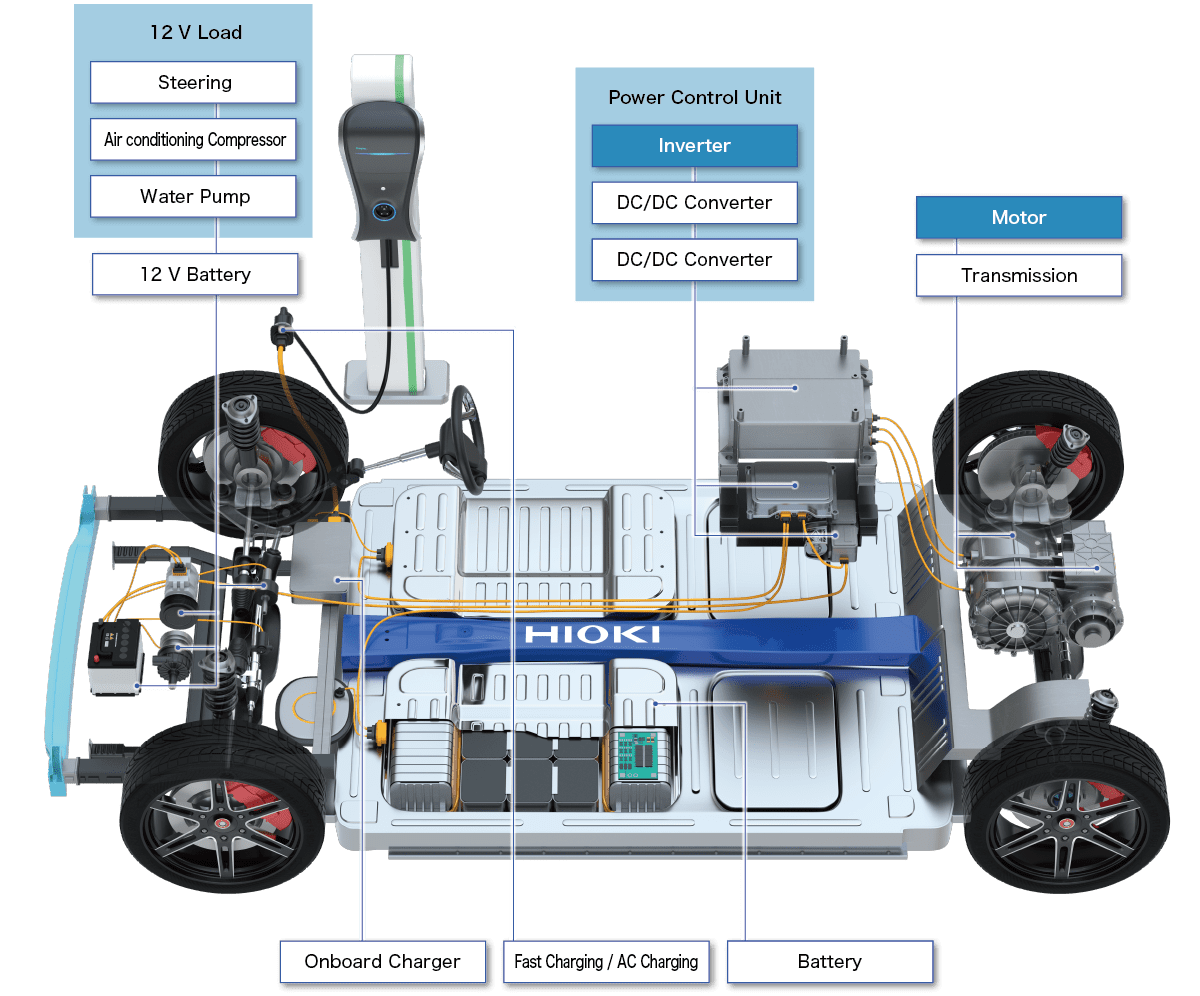

EV and EV Motor Evaluation Using CAN/CAN FD

Accurately assess behavior during HILS testing and vehicle evaluation by simultaneously measuring control and sensor data on the CAN bus and actual analog values.

Measuring Dynamic Motor Characteristics

Record inverter output voltage and current, torque, and RPM from motor start to stop.

Calculate inver ter output power, motor power, and motor efficiency using waveform calculations.

Calculate inver ter output power, motor power, and motor efficiency using waveform calculations.

Measuring Motor Torque Vibrations

Measure torque and vibration, and analyzebehavior during motor operation.

Discover resonance phenomena and other unpredicted frequency components by using FFT calculations to perform a frequency analysis.

Discover resonance phenomena and other unpredicted frequency components by using FFT calculations to perform a frequency analysis.

Measuring Resolver Rotation Angles

A resolver is used as a sensor to accurately measure the angular position of the motor.

Resolvers are used in harsh environments such as industrial motors, servers, and electric vehicles (EVs) because they can operate under demanding conditions for extended period of time. In order to increase EV range, it's necessary to control motors with a high degree of precision so as to boost their energy efficiency.

Resolvers are used in harsh environments such as industrial motors, servers, and electric vehicles (EVs) because they can operate under demanding conditions for extended period of time. In order to increase EV range, it's necessary to control motors with a high degree of precision so as to boost their energy efficiency.

Layer Short Testing of Motor Windings

Detect insulation failures (layer shorts) and deterioration in motor windings.

Generate pass/fail judgments with greater precision than conventional approaches by quantifying response waveforms.

Generate pass/fail judgments with greater precision than conventional approaches by quantifying response waveforms.

Motor Winding Maintenance

Perform impulse testing and use the results in motor winding maintenance and trend management.

Partial Discharge (PD) Testing of Inverter-Driven Motors

Detect latent defects with AC partial discharge testing and surge partial discharge testing.

Motor and Winding Insulation Resistance & Withstand Voltage Testing

Carry out insulation resistance and withstand voltage testing.

Ensure a high level of safety by testing the state of insulation as part of shipping inspections.

Ensure a high level of safety by testing the state of insulation as part of shipping inspections.

Winding Resistance Measurement

Check for wire breaks by measuring winding resistance with a high level of precision.

Check for incorrect wire thickness and turn count by using a high-precision resistance meter to make the measurements.

Check for incorrect wire thickness and turn count by using a high-precision resistance meter to make the measurements.

Motor Coil Inductance Measurement

Measure winding inductance. Check phase balance, motor dynamic performance, RPM variations, and compatibility of the driver motor.

Motor Weld Quality Testing

Test weld quality (check for weld defects) in rectangular wire stators using a DC resistance meter with high resolution and measurement accuracy.