EV Development: Optimize Energy with Precision Tools

The development of electric vehicles prioritizes understanding energy efficiency and power consumption. To achieve this, precise measurement, and analysis of data from various systems, especially batteries, motors, and inverters, are essential. Utilizing high-precision tools such as data loggers and power analyzers enables a thorough understanding of these systems’ performance and facilitates necessary improvements.

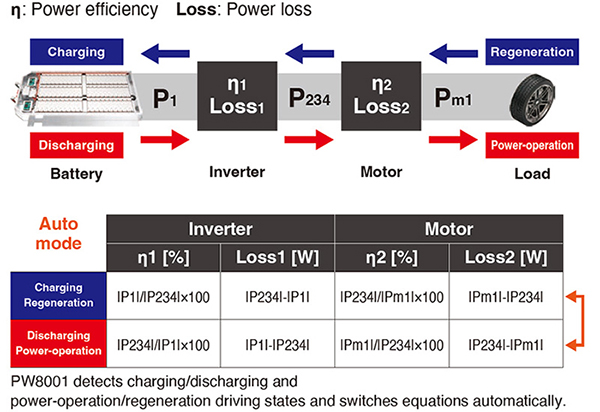

As illustrated in Fig. 1, it is vital to track the dynamic flow of energy, such as charging and discharging, as well as power operation and regeneration—in order to continuously measure efficiency and loss.

Fig. 1

Fig. 1

What are the factors that determine energy efficiency?

One of the factors in understanding the energy efficiency of electric vehicles is power consumption. In the development of electric vehicles, optimizing the efficiency of motors and inverters is key to effectively using limited battery capacity. Here, measuring and analyzing power consumption data using power analyzers is crucial. This data forms the foundation for improving system efficiency.

What are the other factors besides power consumption?

In evaluating xEV systems, efficient energy management of the entire vehicle is required. To achieve this, integrating power data with analog signals like temperature and vibration, along with CAN signals, is important. Integrating these diverse data types enhances the overall system performance and efficiency, leading to extended range and improved ride comfort.

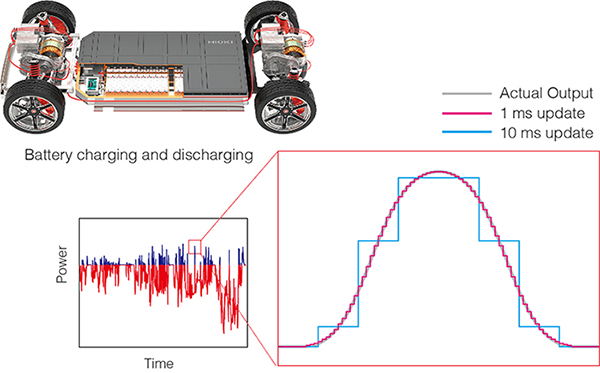

Capture accurate power data and get a complete picture in real time

Enhancing the efficiency of key components like motors and inverters in electric vehicles is essential for improving overall energy performance.

Accurately capturing rapidly fluctuating power data and understanding the entire vehicle's state in real-time is key to building an energy-efficient system. Such comprehensive data analysis enables the improvement of EV performance.

Differences in power data capture due to data update speed

Differences in power data capture due to data update speed

What are the key factors that affect electric vehicle driving range?

Temperature significantly impacts the driving range of electric vehicles. Specifically, data loggers are used to measure temperature and current, and power analyzers to measure power consumption.

Vehicle thermal management is critical

Temperature management in electric vehicles plays a central role in extending range. Properly controlling the thermal environment of the vehicle (thermal management) optimizes battery efficiency and reduces overall energy consumption.

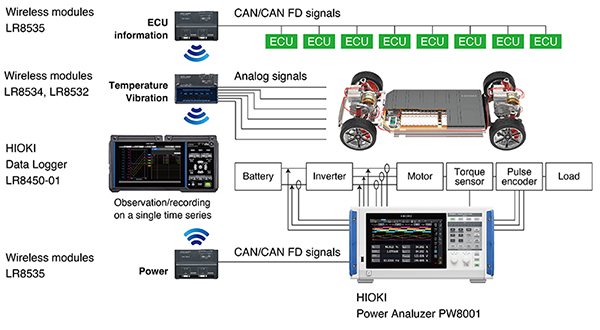

Observe various data simultaneously

Integrating data obtained from data loggers and power analyzers on the same timeline is crucial for devising effective management strategies. Linking data loggers with CAN input and power analyzers with CAN output allows for centralizing diverse data like temperature, current, and power, enabling more accurate analysis.

Observation of analog signals, CAN signals, and power fluctuations on the same time series

Observation of analog signals, CAN signals, and power fluctuations on the same time series

Precise temperature management and data analysis

Such an integrated data management approach significantly reduces the time spent organizing data, contributing to operational efficiency. Accurate and quick data analysis helps formulate and implement strategies to optimize electric vehicle performance and range more swiftly.

Temperature monitoring and data integration in electric vehicles play a crucial role in optimizing energy efficiency and extending range. Accurate temperature management and data analysis are key elements for success in EV development.

How can EV efficiency be improved?

Managing the energy loss is an important factor to improve energy efficiency of electric vehicles.

Besides optimizing the efficiency of crucial components like motors and inverters, understanding DC current (auxiliary DC battery) is necessary to further reduce power consumption. Electrical components in EVs use these DC currents, and their consumption and leakage currents affect the vehicle's overall energy efficiency.

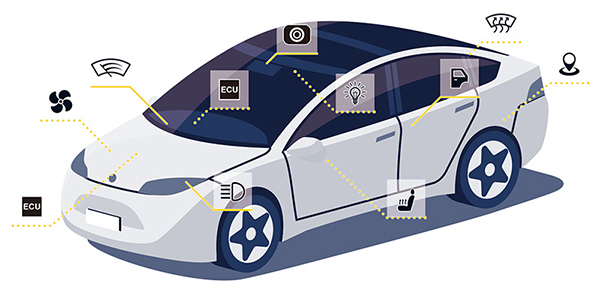

ECUs and electrical components in an electric vehicle

ECUs and electrical components in an electric vehicle

Grasp the current of electrical components

DC current is the lifeline for many electrical components in an electric vehicle, including the ECU (Engine Control Unit), wipers, power windows, heaters, headlamps, and cooling fans. Accurately grasping the consumption and leakage currents of these components is vital to minimize energy loss.

Current Measurement Challenges

Multi-point observation of consumption and leakage currents requires high-accuracy measurement of DC currents, often in the order of tens of milliamperes. Simultaneously measuring these over long periods is not a trivial task.

How to efficiently measure DC current in electric vehicles

Data logger that can perform multi-point observation and a technology to measure tens of milliamps orders with high accuracy is necessary to efficiently measure the DC current of electric vehicles.

Data logger that can efficiently observe current

The HIOKI data logger LR8450-01 is designed to meet such complex measurement needs. This multi-channel data logger, using wireless measurement modules, can be placed near the measurement targets, reducing wiring efforts.

Example of EV current detection by current sensor and image of data collection of distributed measurement points by wireless measurement module

Example of EV current detection by current sensor and image of data collection of distributed measurement points by wireless measurement module

Compact size current sensor

HIOKI’s current modules U8556, wireless current module LR8536, current sensors CT7812 (2A) , and CT7822 (20A) are noted for their compact size. They can easily access complex wiring and efficiently operate in confined spaces like those inside an electric vehicle. These tools, capable of high-accuracy measurements, are suitable for onboard measurements and effectively monitor EV energy loss, thereby aiding in improving the overall energy efficiency of the electric vehicle.

Complicated wiring requires a slim design current sensor

Complicated wiring requires a slim design current sensor

What instruments are used to measure energy efficiency?

Accurately measuring power consumption is important for evaluating energy efficiency in electric vehicles. This requires a combination of precision instruments, each serving a specific role:

Related products

- Power Consumption Measurement

Power Analyzer PW8001World-class measurement accuracy: Basic accuracy ±0.03%, DC accuracy ±0.05%, 50 kHz accuracy 0.2% (When using the 15MS/S Input Unit U7005).

- Current Detection (by connecting to Power Analyzer)

AC/DC Current Sensor CT6904A (500 A)The CT6904A has a frequency bandwidth of DC to 4 MHz, which is top-class for a 500 A rated pass-through sensor.

- Data logging of temperature, current consumption, and dark current

Data Logger LR8450-011ms Sampling Portable Logger Expandable to 330 Channels with Your Choice of Plug-in or Wireless Input Modules.

- DC current detection

Current Sensor CT7812 (2 A) and CT7822 (20 A)Easy to install in confined locations with complex wiring.