Battery Pack Voltage Measurement: What You Need to Know

In electric vehicle (EV) development, extending driving range and reducing charging time are critical factors for improving overall performance. To meet these demands, charge/discharge testing of battery packs is conducted, and data loggers are used to precisely measure the voltage and temperature of each individual cell.

As EV battery systems continue to shift toward higher voltages, ensuring safe and efficient measurement becomes increasingly important. This article outlines the key considerations for accurately monitoring voltage and temperature in high-voltage battery packs, helping to support safer and more efficient EV development.

What matters when evaluating battery performance?

A battery pack is made up of multiple cells connected in series. Even slight variations in individual cell characteristics can significantly affect the overall performance of the battery pack. That’s why it’s essential to monitor voltage and temperature at the cell level, and not just the pack level.

A core aspect of EV development is assessing battery pack performance, primarily through charge-discharge testing. This involves repeatedly charging and discharging the battery pack over a specific period to evaluate its performance, durability, and safety. Accurately recording the battery’s voltage and temperature data during these tests is vital. High-precision data loggers are recommended for this purpose.

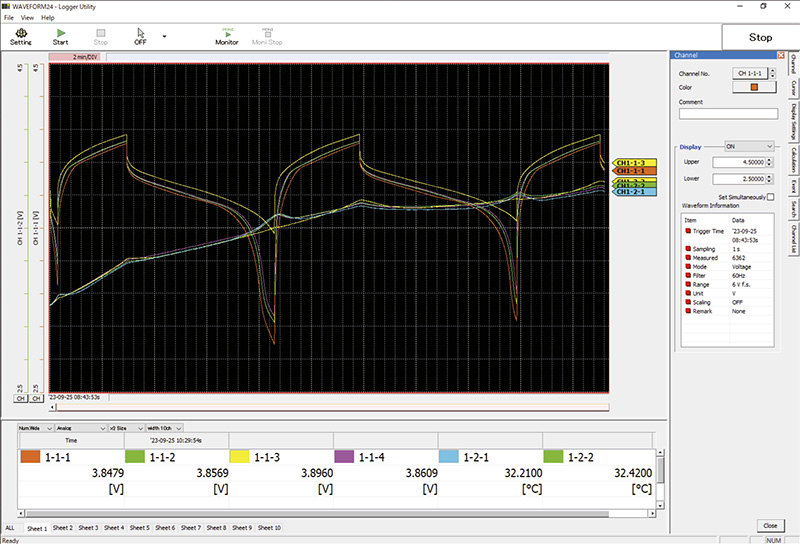

Example waveform of charge/discharge characteristics of a battery pack (charging voltage and package temperature)

Example waveform of charge/discharge characteristics of a battery pack (charging voltage and package temperature)

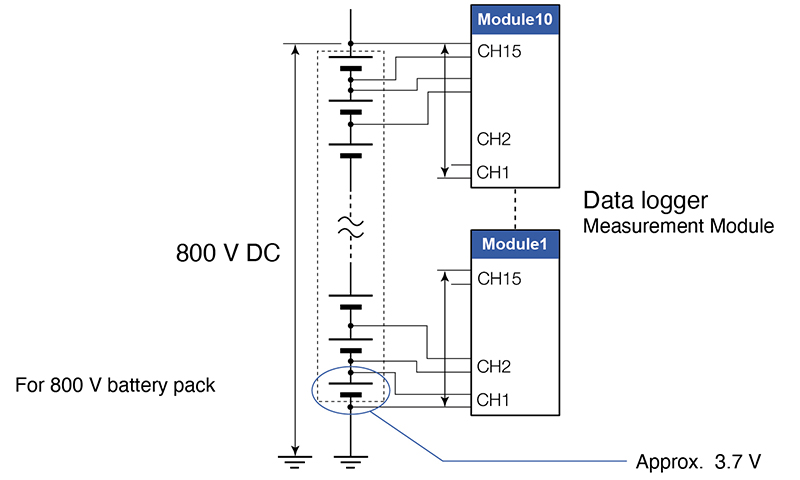

Fig. 1: Terminal-to-ground voltage

Fig. 1: Terminal-to-ground voltage

Higher voltage demands for battery packs

Extending electric vehicle range and reducing charging time is crucial for performance improvement, hinging on increasing battery pack voltage.

Accurate measurement of each cell's voltage and temperature during charge-discharge tests is essential, forming the basis for the overall performance assessment of the battery pack. Thus, data loggers used in these tests require specific features like high insulation input, withstand voltage, and multi-channel functionality. Choosing data loggers designed for high-voltage usage ensures safer and more accurate data collection.

Why insulation performance matters in battery measurement

The voltage of a single cell is around 3.7 V, but the data logger's ground potential is subjected to the high voltage of the stacked cells. Therefore, data loggers with high insulation performance are required.

In charge-discharge evaluation tests, recording the voltage and temperature helps understand battery characteristics. Battery packs consist of numerous cells connected in series. A single cell's malfunction can lead to overall performance degradation, making it essential to understand each cell's behavior.

As shown in Fig. 1, a high voltage is applied between the input channels and ground of the data logger.

With further increase in battery pack voltage, the number of cells also increases. Therefore, data loggers capable of expanding the number of channels and offering flexible configurations are needed.

Choosing the Right Data Logger for Battery Applications

Hioki Data Logger LR8101, LR8102 are equipped with modules dedicated to high-voltage measurements. These modules are compatible with a ground-to-ground voltage of 1500 V, allowing safe cell voltage measurement even with battery packs of 800 V or more. This characteristic is especially important in the modern trend of higher voltage EV battery packs. In addition, these data loggers can be linked together with measurement modules and are highly scalable. This makes it possible to measure the voltage and temperature of each cell of the battery pack individually and accurately, as well as to measure multiple battery packs and other electrical components at the same time. This scalability is also essential for the meticulous analysis and optimization of complex EV systems.