Product Jan. 05, 2022

Hioki Wins Nagano Institute of Invention and Innovation Chairman’s Prize for Invention Related to Electrode Resistance Measurement System at the 2021 Kanto Region Invention and Innovation Awards

Hioki is pleased to announce that its invention of an electrode resistance measurement system (patent No. 6472664) has been recognized with the Nagano Institute of Invention and Innovation Chairman’s Prize at the 2021 Kanto Region Invention and Innovation Awards, which were hosted by the Japan Institute of Invention and Innovation. The honor came in response to Hioki’s first submission of an invention to the regional award program.

The program, which was founded in 1921, recognizes engineers, researchers, and developers who realize exceptional inventions, ideas or designs in eight regions nationwide (Hokkaido, Tohoku, Kanto, Chubu, Kinki, Chugoku, Shikoku, and Kyushu).

The accolade recognized what is the world’s first technology for evaluating electrode sheets, a major component of lithium-ion batteries (LIBs), for its ability to:

(1) Generate a numerical index of contact resistance at the interface between different conductive materials, which cannot be contacted from outside a battery.

(2) Significantly reduce development times and improve development efficiency for LIBs by allowing the evaluation process to be performed before electrode sheets are embedded in battery cells.

(3) Help extend LiB service life and improve safety and performance by providing the ability to evaluate variations (uniformity) inside the materials of electrode sheets.

(4) Simplify the process of evaluating electrode sheet performance and facilitate quantitative evaluation of parameters such as batteries’ rapid charging and discharging characteristics.

These technologies can be used to make quantitative evaluations of the characteristics and quality of rechargeable batteries such as LiBs, yielding new evaluation indicators that will be effective in extending the service life and improving the safety and performance of rechargeable batteries. In this way, they will help realize a low-carbon society through such transformations as the shift to electric vehicles (EVs) and the achievement of carbon neutrality.

Hioki will continue to pursue research and technological development to bring value to people worldwide and help realize a sustainable society.

Award and recipients

Nagano Institute of Invention and Innovation Chairman’s Prize

Electrode resistance measurement system (patent No. 6472664)

Yuki Kawamuro, EM Unit, HIOKI E.E. CORPORATION

Nobuhisa Handa, EM Unit, HIOKI E.E. CORPORATION

Tetsuya Takahashi, Manager, EM Unit, HIOKI E.E. CORPORATION

Introduction to a product that uses the award-winning invention

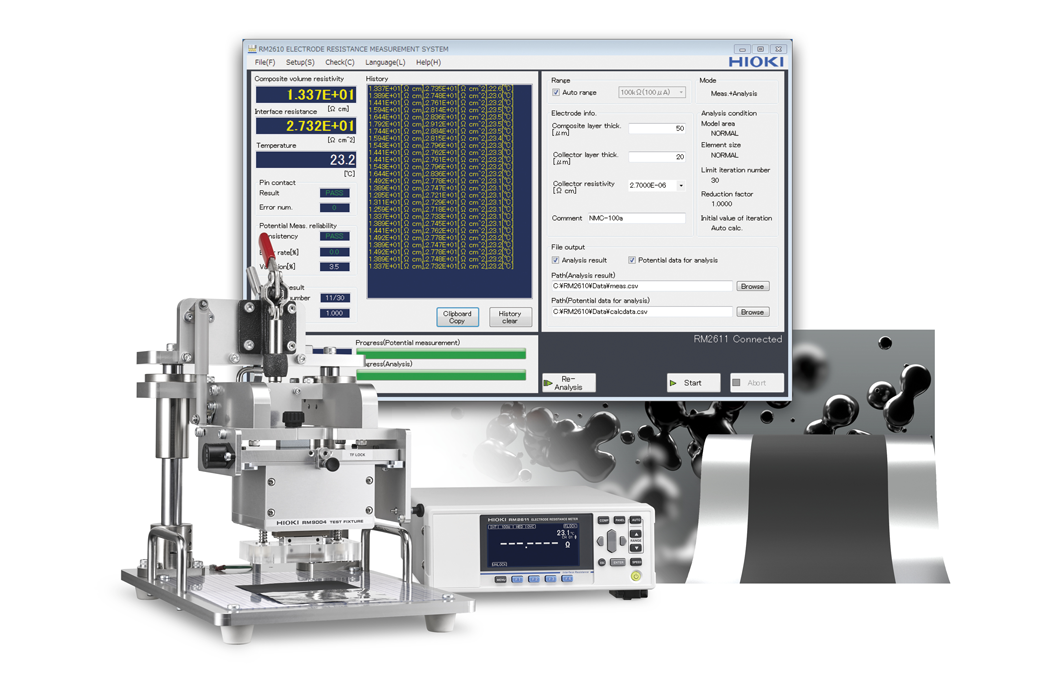

The RM2610 Electrode Resistance Measurement System is a quantification and measurement system that isolates the resistance characteristics of electrode sheets, a major component of LIBs, into the composite layer resistance and the interface resistance between the composite layer and the collector. Potential is measured by placing a test fixture (consisting of test probes) in contact with the surface of an electrode sheet. Then a proprietary Hioki analytical method is used to visualize the composite layer resistance and the interface resistance between the composite layer and the collector.

In the past, it was not possible to evaluate electrode sheets until the LiB containing them was assembled, requiring companies to spend valuable man-hours on prototype production. In addition, the conventional measurement method (measuring pass-through resistance and volume resistivity using the 4-probe method) measured only the electrode sheet’s overall resistance characteristics. There was no method for ascertaining the electrode sheet’s composite layer resistance or the interface resistance between the composite layer and the collector. The ability to assess these resistance characteristics dramatically improves LiB quality and development efficiency, not only by allowing engineers to make detailed observations of how different materials, compositions, and manufacturing conditions can improve performance, but also by enabling evaluation at the electrode sheet stage.

About HIOKI

Established in 1935, HIOKI E.E. CORPORATION (TSE: 6866) has grown to become a world leader in providing consistent delivery of test and measuring instruments through advanced design, manufacturing, and sales and services. By offering over 200 main products characterized by safety and quality while meeting an expansive range of applications, we aim to contribute to the efficiency and value of our customers' work in research and development, production and electrical maintenance. Hioki products and services are available around the world through our extensive network of subsidiaries and distributors. For more information, visit us at www.hioki.com.