Facilitating LiB Market Growth and Environmental Protection

Improve lithium-ion battery (LiB) quality and development efficiency through proprietary electrode resistance measurement technology

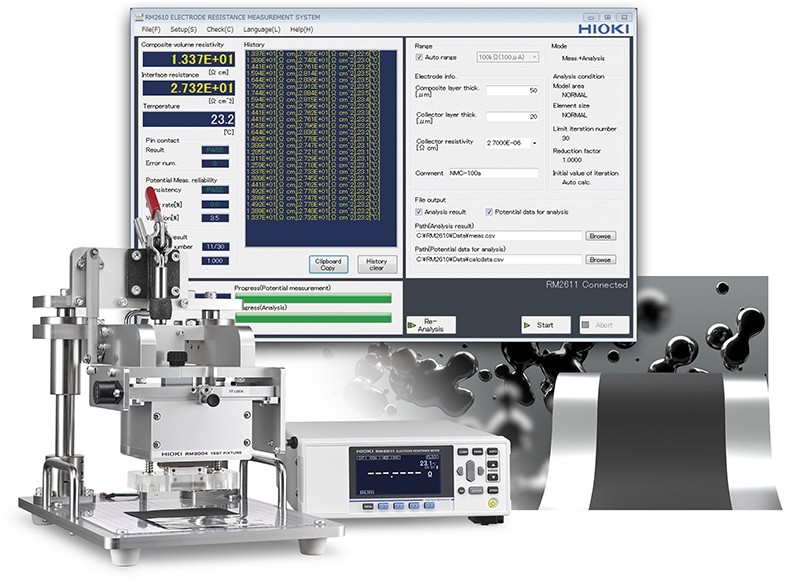

Electrode Resistance Measurement System RM2610

Electrode Resistance Measurement System RM2610

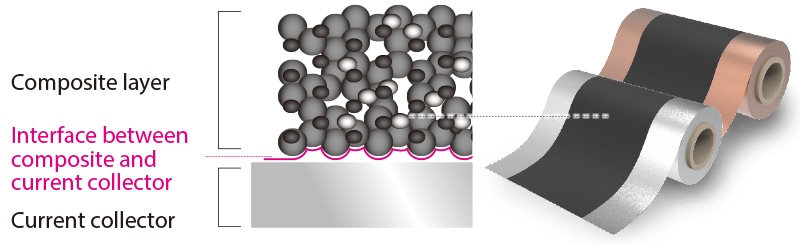

The Electrode Resistance Measurement System RM2610 is a quantification and measurement system that isolates the resistance characteristics of electrode sheets, a major component of lithium-ion batteries (LiBs), into the composite layer resistance and the interface resistance between the composite layer and collector.

By placing a test fixture (with test probes) in contact with the surface of an electrode sheet to measure its potential and then analyzing the results with proprietary Hioki techniques, it is possible to visualize the composite layer resistance and the interface resistance between the composite layer and collector.

In the midst of rapidly growing demand for lithium-ion batteries, battery and material performance as well as quality consistency have become key issues.

Lithium-ion batteries (LiBs) are widely used as rechargeable batteries in compact devices such as smartphones and computers due to their low weight and high capacity. Currently, production volume is growing rapidly worldwide against the backdrop of evolution, improvement, and development as rechargeable batteries for use in electric vehicles (EVs) as the world transitions to a society that is not carbon-dependent.

Since the output and service life of lithium-ion batteries rise as their internal resistance decreases, it’s extremely important to consider the resistance characteristics of electrode sheets, which are a major battery component. However, until recently, no rational evaluation procedure had been discovered.

Electrode sheet diagram

Electrode sheet diagram

Contributing to the evolution and consistent quality of LiBs by proposing a new performance indicator with a proprietary measurement and analysis system

We've made it possible to quantify resistance characteristics, which until now had been impossible to visualize. The approach makes it possible to assess electrode sheet characteristics and quality trends and to visualize changes in resistance characteristics caused by changes in material composition, enabling testing earlier in the lithium-ion battery research and manufacturing process.

Improved yields in research, development, and production processes mean higher productivity.

Helping reduce environmental impacts by contributing to the evolution of lithium-ion batteries

Rechargeable batteries play an essential role in electrifying vehicles and efficiently using renewable energy as environmental awareness grows. Demand for lithium-ion batteries is rising due to adoption of EVs, information technologies (IT), and the Internet of Things (IoT), creating demand for even higher-performance, lower-cost batteries. Our Electrode Resistance Measurement System RM2610 is making a new contribution to lithium-ion battery R&D and cost savings.