Product Mar. 12, 2024

Unfazed by Mud, Rain, or Temperature Extremes: Hioki’s New Accurate Ground/Earth Resistance Meter

HIOKI E.E. COPORATION is pleased to announce release of the new Earth Tester FT6041, designed for verifying the safety of electrical wiring. The new instrument is impervious to the effects of mud, rain, and extreme heat or cold. That’s because IP67*1 dust and water protection combines with a broad operating temperature range of -25°C to 65°C (-13°F to 149°F) to ensure that the product is capable of accurate measurement in even the toughest of environments. Extensive functionality–such as the MEC (Measuring Earth with a Clamp) function for testing live ground wires, and a soil resistivity*2 function for grounding installation design–makes ground testing safer and more efficient.

- *1:IP67: A sealing effectiveness code that indicates the level of dust and water resistance as defined by the IEC 60529 international standard. The code’s two digits indicate the level of protection against solid particles and liquids, respectively. An IP67 device is dust-tight and can be immersed up to 1 meter without penetration of water.

- *2:Soil resistivity: A property that quantifies the ease with which current flows to the ground underfoot. In addition to being affected by geological properties of the ground (for example, whether it’s comprised of sand or rock), this value fluctuates with temperature and humidity. It is used to design grounding installations prior to their installation.

Development background

Electricity, which doesn’t directly generate CO2 directly during use, will be an important type of energy as we work to realize a clean, sustainable society. As the scope of its use broadens beyond household appliances like air conditioners and LED lighting to include new applications like electric vehicles (EVs) and solar power systems, the importance of electricity in society will only grow.

Grounding wires are critical for ensuring that electrical products operate in a safe and reliable manner. Grounding connections serve to safely route electricity leakage and hazardous voltages on electric wiring back to the ground underfoot. Ground resistance meters (like the Earth Tester FT6401) are essential tools for verifying that grounding connections have been reliably made to ensure electrical safety in buildings. Since such instruments measure the soil/ground, making contact with mud, water, and other substances in harsh environments is unavoidable. Moreover, extreme temperatures can cause instruments to malfunction or temporary freeze operation, interfering with work during extended periods of outdoor use. In short, ground resistance meters must be durable in the face of harsh environments so that work can be completed efficiently.

In addition, recent years have seen the field measuring instrument market make many improvements that improve on-site efficiency and safety. The prevalence of these improvements has pushed instrument makers to supply these improvements as standard functions. In this new Earth Tester, Hioki has answered calls by users in providing two new functions to ship standard: the ability to make measurements without shutting off building power and the ability to measure soil resistivity so that ground resistance can be managed more effectively. By supplying the FT6041 as an efficient, accurate ground resistance meter, Hioki is proposing solutions that can help realize a future characterized by safe and reliable electricity use.

What does “grounding” mean

Grounding means making an electrical connection between an electrical device or a building and the ground underfoot to facilitate safe use of electricity. Proper installation ensures safe electrical wiring by preventing electric shock and fire.

Another purpose of grounding is to avoid power quality issues such as power outages and malfunctions of electrical devices by routing high-frequency noise from the wiring to the ground underfoot. Grounding must be installed in compliance with laws and standards as well as be regularly maintained in order to ensure ground resistance values remain within safe levels.

Durability against harsh exposure of mud, sand, and extreme temperatures

Ground resistance meters are often used outdoors. In harsh environments where ground resistance meters are exposed to mud, sand, and puddles, water and dust protection is an essential product feature. These instruments must continue to operate properly even in environments characterized by extreme weather or temperatures, including areas with intense heat or cold weather. The FT6041 delivers reliable, malfunction-free measurement thanks to its IP67 dust/water protection and broad operating temperature range of -25°C to 65°C (-13°F to 149°F).

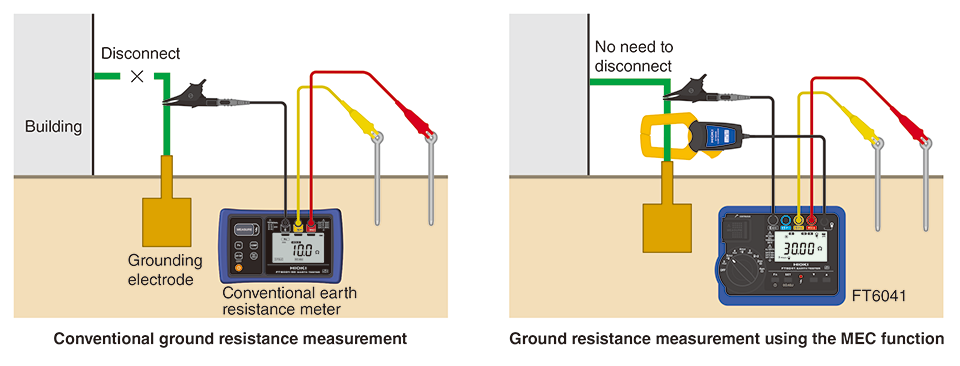

MEC function: measure ground resistance without disconnecting grounding electrodes

The conventional approach to measuring ground resistance requires that grounding electrodes be disconnected from the building’s electrical wiring, necessitating that the power be turned off at the site. However, it's not practical to shut off power at facilities like datacenters and hospitals, which must operate 24 hours a day. Moreover, that approach is more time-consuming as it requires tasks like disconnecting wiring in advance and verifying that the re-installation was successful. Using the newly developed sensors that can detect minuscule currents, the FT6041 can make measurements without requiring the power be turned off.

Soil resistivity measurement, a useful tool for grounding installation design

Structures like buildings and factories often use structural grounding, an approach that uses steel beams as grounding electrodes. In buildings that use structural grounding, rods/piles driven into the soil act like gigantic grounding electrodes. In such installations, ground resistance values are affected by the properties of the soil in the location where the building was built. Soil resistivity—which is in essence how much electricity-flow is impeded or resisted by the soil—varies with these geological properties. Knowing the resistivity can be useful when evaluating structural grounding installations. For example, the size, shape, and material of the grounding rod/pile also affects the final ground resistance values. Measuring the soil resistivity beforehand with the FT6041 allows building designers to estimate the time, effort, and price for installing the necessary grounding without starting their detailed design and calculations.

Applications

- Testing the ground resistance of electric-system wiring in buildings

- Testing the ground resistance of electrical equipment such as transformers and motors

- Testing the ground resistance of transmission towers, lightning rods, and other structures

Link

Contact us

For inquiries such as quotes, demonstrations, and trial usage, please use Hioki’s contact form for a personalized reply from your closest or most appropriate Hioki representative.

- The information provided is current as of the date of publishing.

- Please note that prices, specifications, and other information contained in this texts are subject to change without notice.

- The company names and product names used in this text are registered trademarks or trademarks of their respective companies.

About HIOKI

Established in 1935, HIOKI E.E. CORPORATION (TSE: 6866) has grown to become a world leader in providing consistent delivery of test and measuring instruments through advanced design, manufacturing, and sales and services. By offering over 200 main products characterized by safety and quality while meeting an expansive range of applications, we aim to contribute to the efficiency and value of our customers' work in research and development, production and electrical maintenance. Hioki products and services are available around the world through our extensive network of subsidiaries and distributors. For more information, visit us at www.hioki.com.